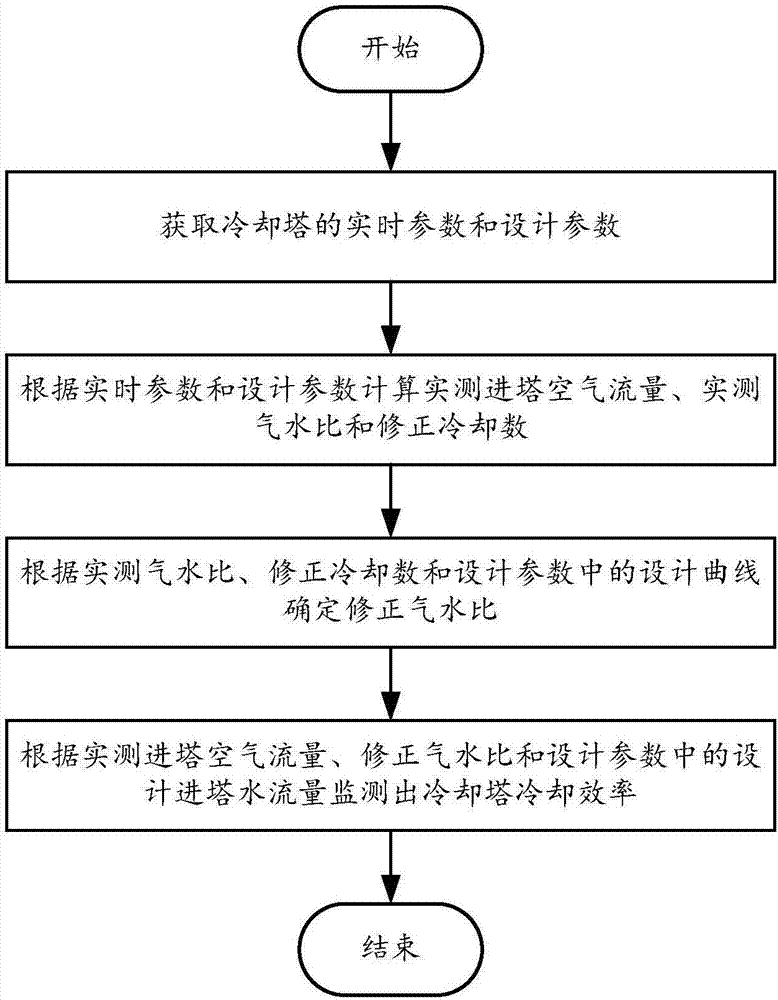

Method and system for monitoring cooling efficiency of cooling tower

A cooling efficiency and cooling tower technology, applied in the field of testing, can solve the problems of high labor costs, inability to monitor the operation status of cooling towers for a long time, and poor timeliness, and achieve the effects of strong timeliness, reduced labor costs, and fast and accurate monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

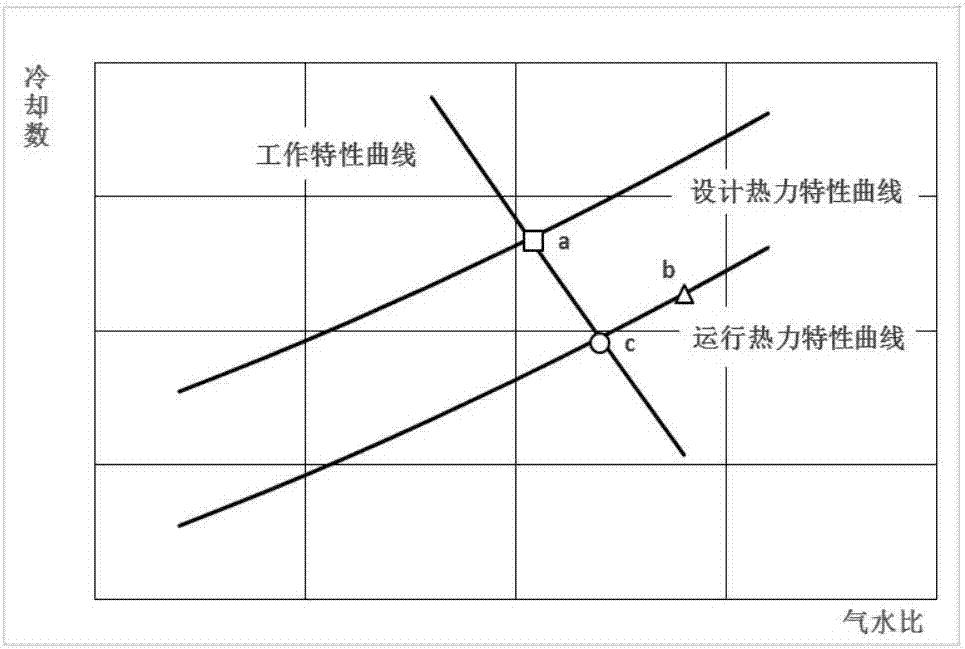

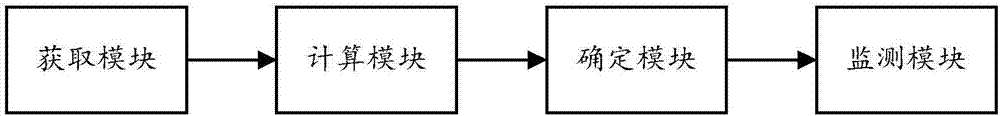

Method used

Image

Examples

Embodiment Construction

[0056] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0057]A cooling tower is a device that uses water as a circulating coolant to discharge waste heat from industrial production or refrigeration processes into the atmosphere. Its principle is to use water and air to exchange heat and cold to generate steam, and the steam evaporates to take away heat to achieve cooling. Cooling towers are divided into: natural ventilation cooling towers, mechanical ventilation cooling towers and mixed ventilation cooling towers according to ventilation methods; cooling towers are divided into wet cooling towers, dry cooling towers and wet and dry cooling towers according to the contact mode of hot water and air Tower; Cooling towers are divided into counter-flow cooling towers, cross-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com