Method for quantitatively determining content of various types of heavy metal in fly ash by adopting XRF (X-ray Fluorescence) instrument

A technology for quantitative determination of heavy metals, applied in the field of environmental engineering, can solve the problem of lack of rapid, accurate and quantitative determination of fly ash, etc., and achieve the effect of strong timeliness, simple operation and rapid determination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Sample pretreatment

[0038] The fly ash produced in the flue gas purification system of the domestic waste incineration plant was taken as the sample to be tested.

[0039] 2. Preparation of fly ash standard samples

[0040]The ratio by weight is 6:4. Calcium oxide and silicon dioxide are mixed to form the base material. Then take a fly ash standard sample of known concentration, add the base material and mix, the weight ratio of the base material to the fly ash standard sample is 5:0~0:5, so as to make a fly ash standard sample. Wherein, the concentration of lead in the fly ash standard sample is 5000 mg / kg, the concentration of chromium is 810 mg / kg, the concentration of copper is 1050 mg / kg, the concentration of zinc is 16800 mg / kg, the concentration of arsenic is 54 mg / kg, cesium The concentration of cadmium is 18.3mg / kg, the concentration of cadmium is 226mg / kg, and the concentration of barium is 4650mg / kg.

[0041] 3. Determination

[0042] The sample to b...

Embodiment 2

[0048] 1. Sample pretreatment

[0049] The fly ash produced in the flue gas purification system of the domestic waste incineration plant was taken as the sample to be tested.

[0050] 2. Preparation of control samples

[0051] The ratio by weight is 3:7-7:3, calcium oxide and silicon dioxide are mixed to form the base material. Then take a fly ash standard sample of known concentration, add the base material and mix, the weight ratio of the base material and the fly ash standard sample added is 4:1~1:4, so as to make a fly ash standard sample. Wherein, the concentration of lead in the fly ash standard sample is 800-6000 mg / kg, the concentration of chromium is 60-4000 mg / kg, the concentration of copper is 300-6500 mg / kg, the concentration of zinc is 2500-75000 mg / kg, the concentration of arsenic The concentration of cesium is 5-150mg / kg, the concentration of cesium is 1-50mg / kg, the concentration of cadmium is 160-350mg / kg, and the concentration of barium is 200-12000mg / kg. ...

Embodiment 3

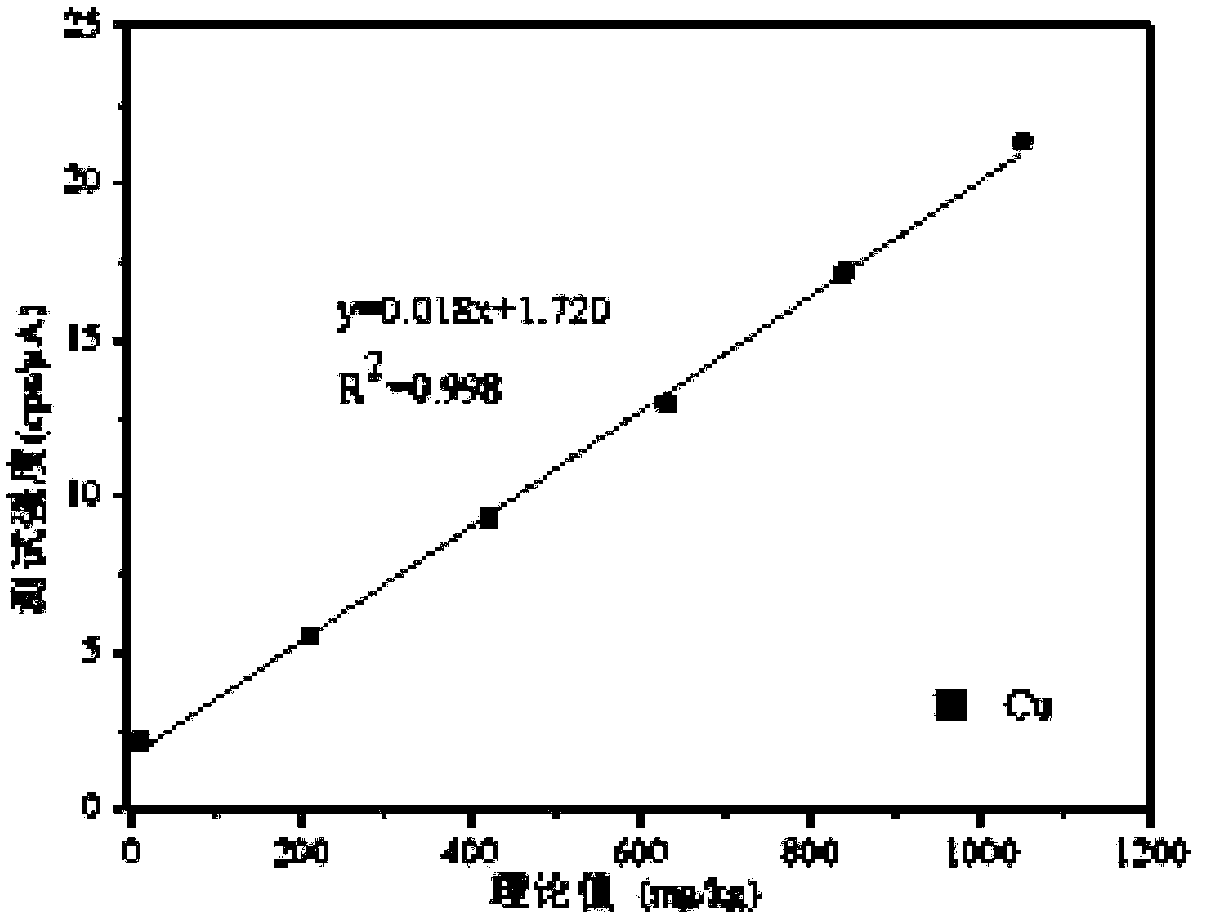

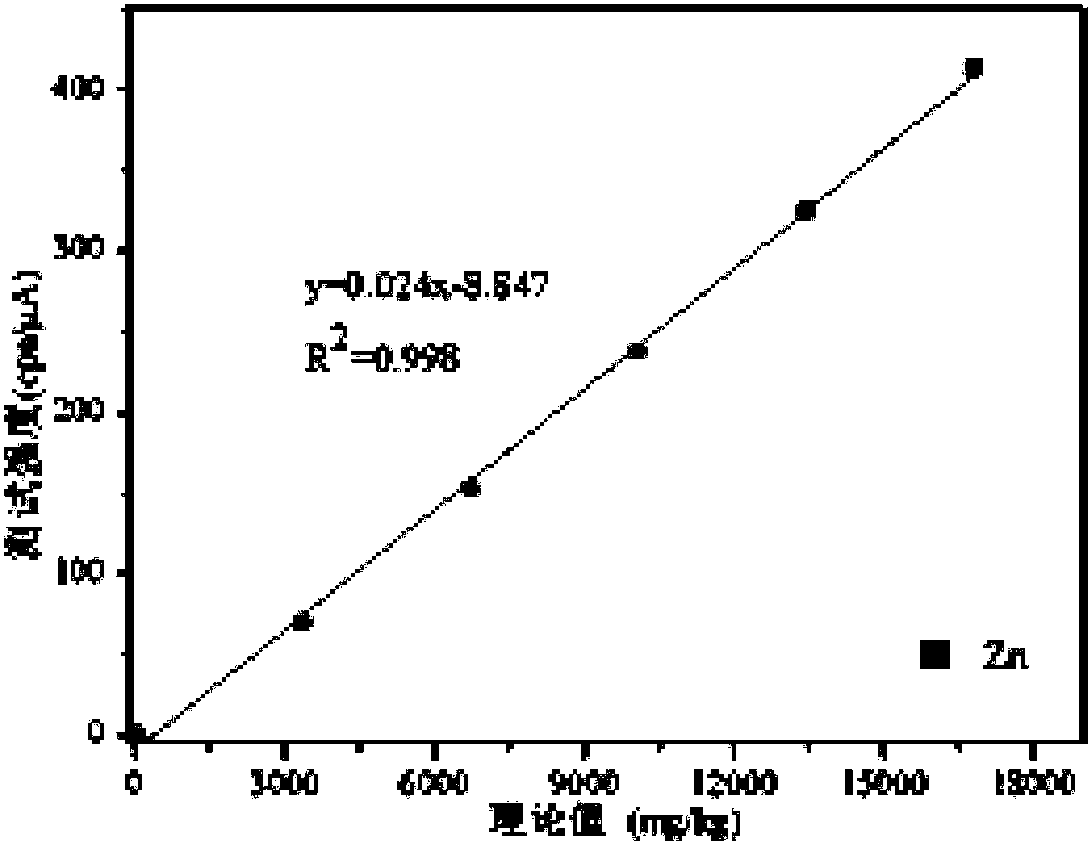

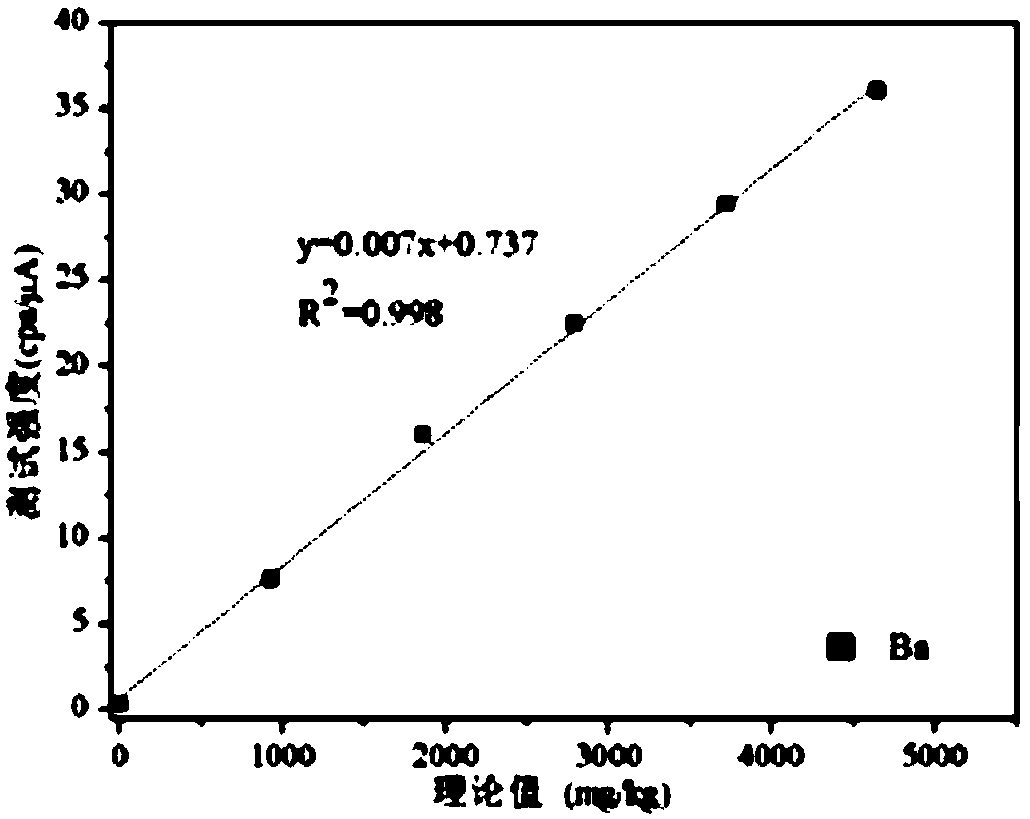

[0059] According to the preparation method of the fly ash standard sample in step 2 of Example 1, the ratio by weight is 6:4, and calcium oxide and silicon dioxide are mixed to form the base material. Then take a fly ash standard sample of known concentration, add the base material to mix, the weight ratio of the base material to the fly ash standard sample is 5:0, 4:1, 3:2, 2:3, 1:4, 0:5, a total of 6 fly ash standard samples were prepared, and according to the content values of various heavy metal elements in the fly ash standard samples, the content values of each heavy metal element in the 6 fly ash standard samples were calculated. The specific contents of eight heavy metal elements including Pb, Cr, Cu, Zn, As, Se, Cd and Ba are shown in Table 1.

[0060] Table 1 Contents of eight heavy metal elements in fly ash standard samples / (mg / kg)

[0061]

[0062] Take 5g of the 6 fly ash standard samples and put them into the sample test box supporting the XRF instrument....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com