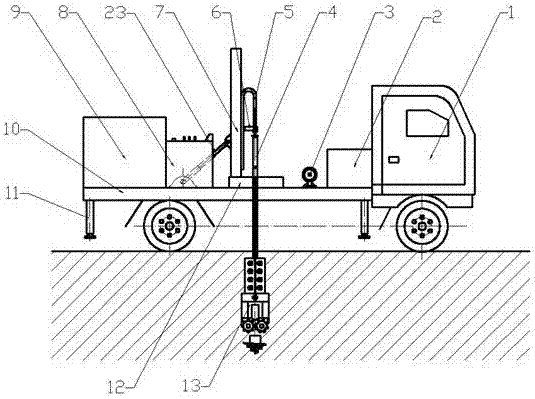

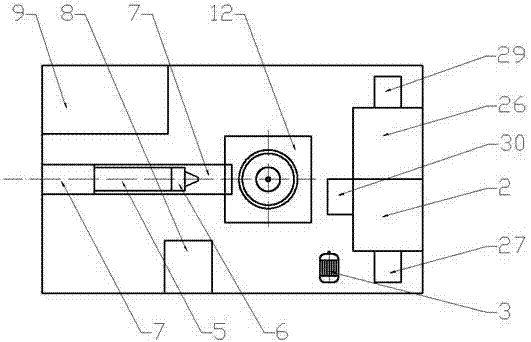

Horizontal foundation bearing capacity testing equipment and testing method

A technology for ground bearing capacity and testing equipment, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve problems such as large errors in experimental data, achieve small disturbance, accurate experimental data, and reduce manpower physical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

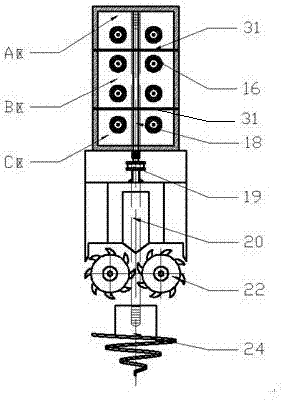

[0038]Embodiment 1. The inside of the steel plate frame 15 is provided with two layers of sliding devices 31, and the inside of the steel plate frame 15 is divided into three test work areas, wherein A area and C area are two areas for removing boundary effects, and B area is an intermediate test area . During the experiment, the test jack groups 16 inside the areas A, B, and C applied pressure to both sides at the same time to obtain experimental data. In order to make the experimental data more authentic, the data of the intermediate test area (B area) is taken as the final experimental data.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com