Battery pack with a separating device

A separation device and battery pack technology, applied in the vehicle field of battery packs, can solve problems such as electrical hazards for rescuers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

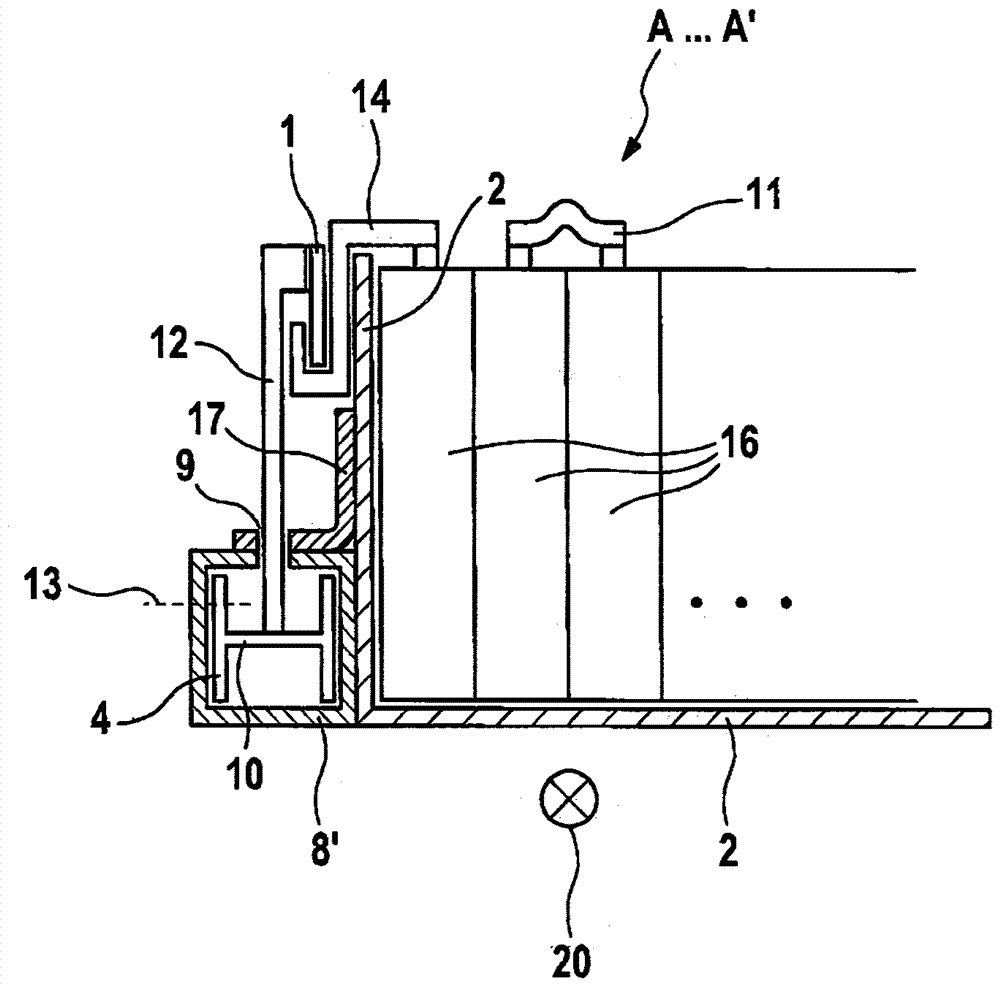

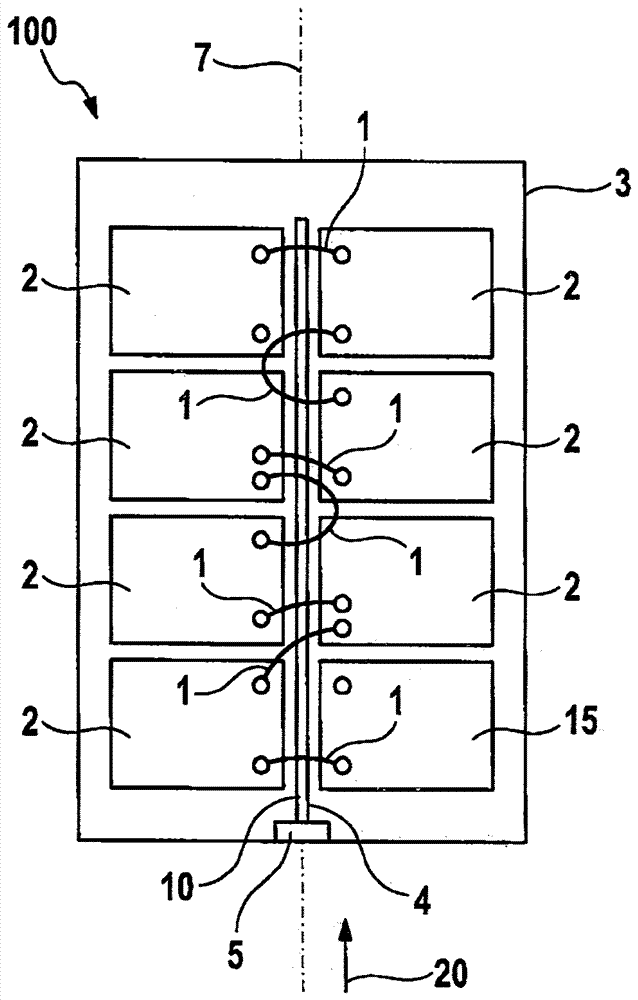

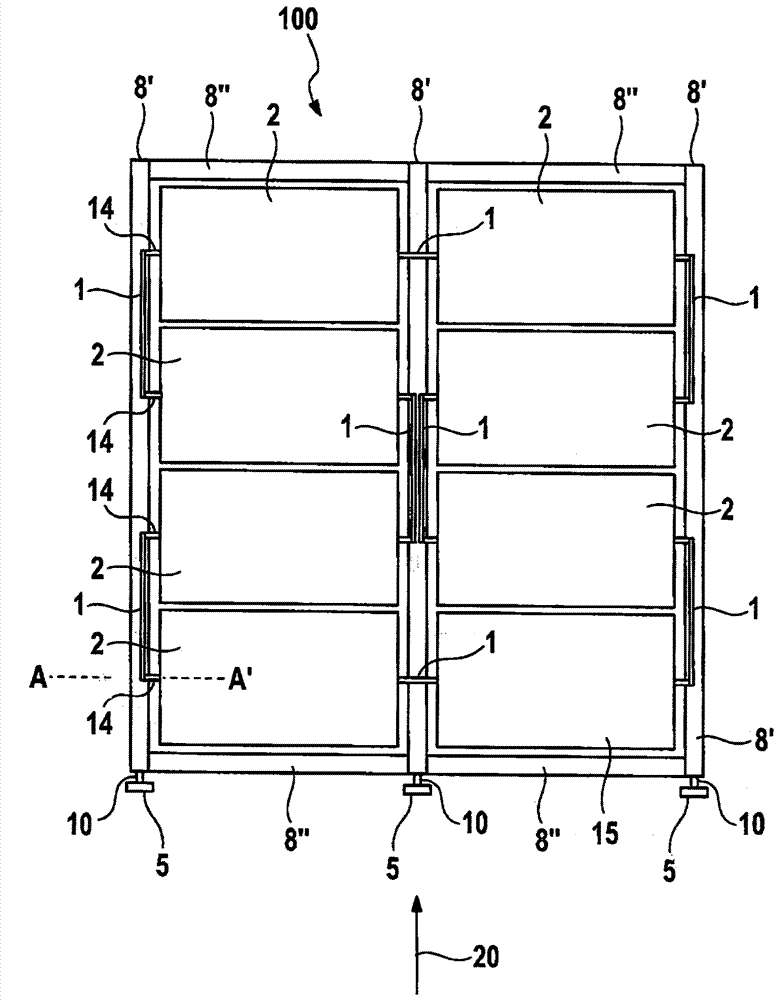

[0030] figure 1 A battery pack 100 is shown, which is arranged in the installation space 3 . Here, by figure 1 A separating device 10 for separating a plurality of battery modules 2 connected in series is clearly visible, in which battery modules 2 are electrically connected to one another via releasably pluggable module connectors 1 . The separating device 10 has a separating rail 4 displaceable in its longitudinal direction 20 , which is arranged centrally between the battery modules 2 on a central axis 7 . The separation device 10 is arranged along one side of the battery module 2 and is mechanically connected with a plurality of module connectors 1 traversing the separation device. The electrical connection via the releasably pluggable modular connector 1 is detachable by movement of the separating rail 4 in its longitudinal direction 20 . The battery pack 100 includes a battery control unit BCU 15 in addition to the battery module 2 . During the deformation of the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com