Molecular assembly superstructure materials based on core molecules, preparation methods and applications

A core molecule, super structure technology, applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problem of particle dependence, etc., to improve the content and loading of sulfur, high porosity and specific surface area, improve specific energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

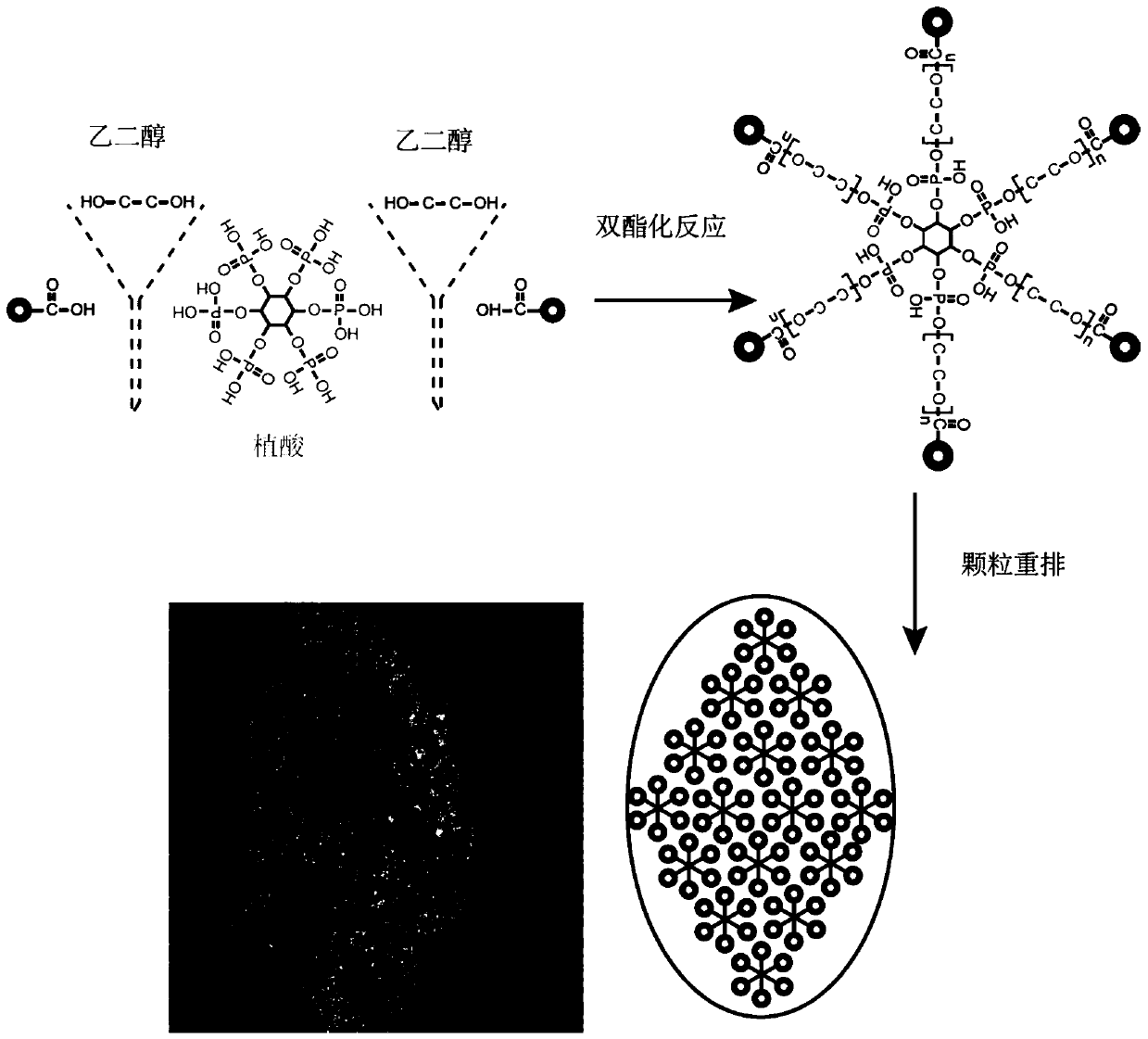

Method used

Image

Examples

Embodiment 1

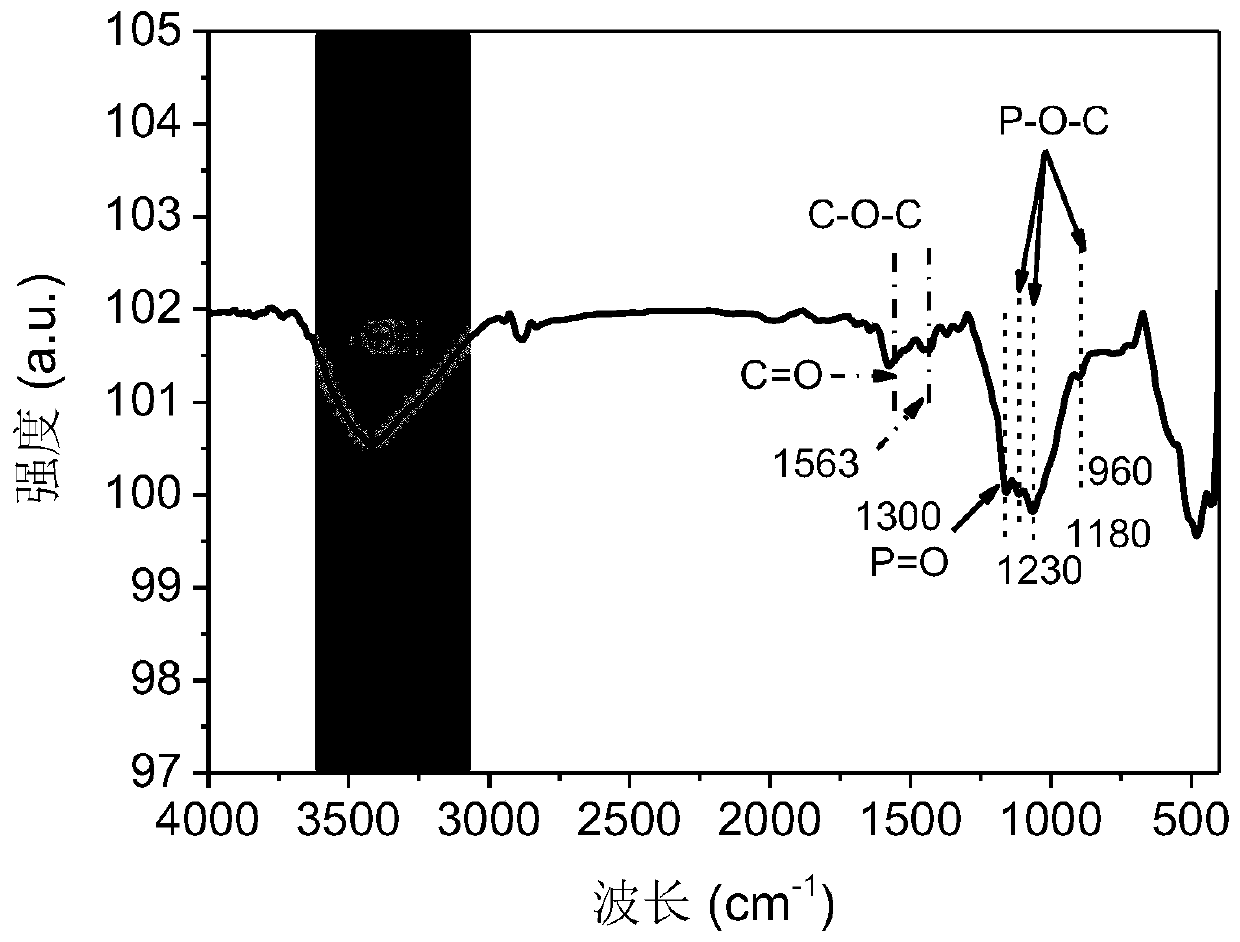

[0056] Disperse 1 g of nano-scale Ketjen black in 60 mL of commercially available concentrated nitric acid, react at 130 °C for 1 h under reflux conditions, wash with deionized water to neutrality and dry at 60 °C to obtain 1 g of nano-scale carboxylic acid Acidified Ketjen Black, dispersed in 100mL of deionized water, mixed with 0.5g of phytic acid, fully dissolved at 30°C; then firstly added 0.7587mL of ethylene glycol, then 0.87 g ammonium persulfate, heated to 130°C for 2h to form phosphate bond and carbonate bond; cooled to room temperature, filtered to obtain a solid, then washed with deionized water until the pH was neutral, and then dried at 120°C for 6h A reaction product is obtained; the reaction product is calcined at 1000° C. under an argon atmosphere, and the obtained powder is the aforementioned molecular assembly superstructure material based on core molecules.

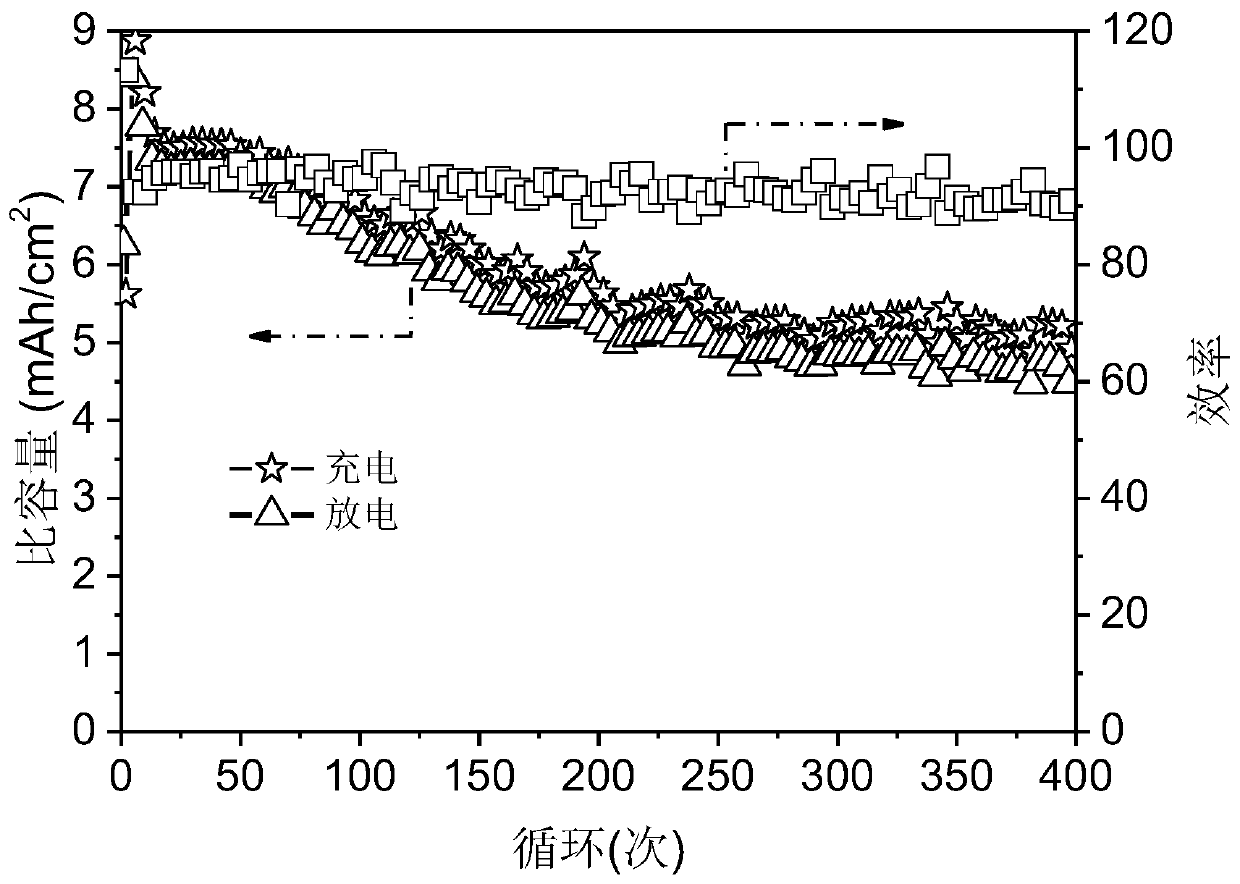

[0057] 100 mg of the molecular assembly superstructure material based on the core molecule obtained ...

Embodiment 2

[0066] Disperse 1g of nano-scale Ketjen Black in 60mL of 1mol / L orthophosphoric acid, react at 130°C for 1h under reflux conditions, wash with deionized water until neutral and dry at 60°C to obtain 1g of nano-scale Phosphorylated Ketjen black, dispersed in 100mL ethanol, mixed with 0.5g phytic acid, fully dissolved at 30°C; then firstly added 0.7587mL ethylene glycol, then 0.87g Ammonium persulfate, heated to 130°C for 2 hours of connection reaction to form a phosphate bond; cooled to room temperature, filtered to obtain a solid, then washed with deionized water until the pH was neutral, and then dried at 120°C for 6 hours to obtain the reaction product; The reaction product is calcined at 1000° C. under an argon atmosphere, and the obtained powder is the molecular assembly superstructure material based on core molecules.

[0067] Evenly disperse 100 mg of the core molecule-based molecular assembly superstructure material obtained in this example in 100 mL of deionized water ...

Embodiment 3

[0076] Disperse 1g of nano-scale Ketjen black in 60mL of 1mol / L benzenesulfonic acid, react at 130°C for 1h under reflux conditions, wash with deionized water until neutral and dry at 60°C to obtain 1g of nano-scale Grade sulfonated Ketjen Black, dispersed in 100mL of isopropanol, mixed with 0.5g of phytic acid, fully dissolved at 30°C; then firstly added 0.7587mL of ethylene glycol under stirring and condensing reflux at 500rpm, then Add 0.87g of ammonium persulfate, heat to 130°C for connection reaction for 2h, form phosphate bond and sulfonate bond; cool to room temperature, filter to obtain solid, then wash with deionized water until the pH is neutral, and then in 120°C The reaction product was obtained by drying at low temperature for 6 hours; the reaction product was calcined at 1000° C. under an argon atmosphere, and the obtained powder was the aforementioned molecular assembly superstructure material based on core molecules.

[0077] Evenly disperse 100 mg of the core ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com