Gluing machine

A glue applicator and glue bucket technology, applied in the field of glue applicators, can solve the problems of poor glue applicator effect, low production efficiency, time-consuming and laborious, etc., and achieve good glue applicator effect, improved production efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

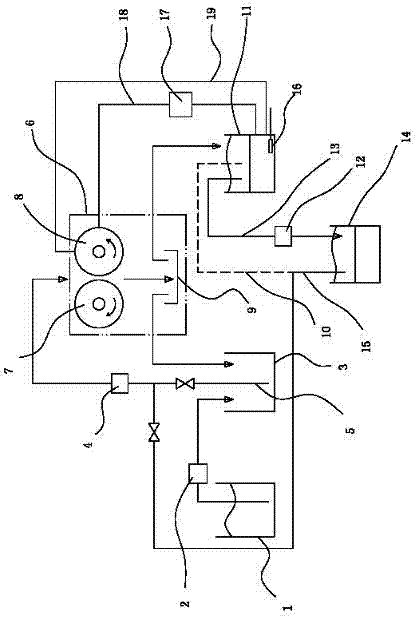

[0010] Glue applicator principle of the present invention is as figure 1 As shown, according to its working process, it is divided into four parts:

[0011] 1. Glue supply and circulation:

[0012] The first glue barrel 1 is filled with glue, which is delivered to the second glue barrel 3 by the glue delivery pump 2, and the glue in the second glue barrel 3 is delivered to the main body 6 of the glue applicator by the pump 4 through the glue delivery pipeline 5, and falls Into the I roller 7 and II roller 8, there is a diversion groove 9 under the I roller 7 and II roller 8, during the operation of the equipment, the excess glue falls into the diversion groove 9, the placement of the second rubber barrel 3 The position is just enough to allow the glue in the diversion groove 9 to fall into it.

[0013] 2. Cleaning:

[0014] Cleaning operation is required when the equipment is not performing gluing operations. The cleaning liquid in the cleaning liquid tank 11 is transported...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap