A composite mold set for integrated processing of automobile drive axle housing cover

A technology of composite molds and axle housings, used in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult to meet the quality requirements of the whole vehicle assembly, unstable shaping effect, complex mold structure, etc., and achieve the blank shaping process. Stabilize, improve production tact, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

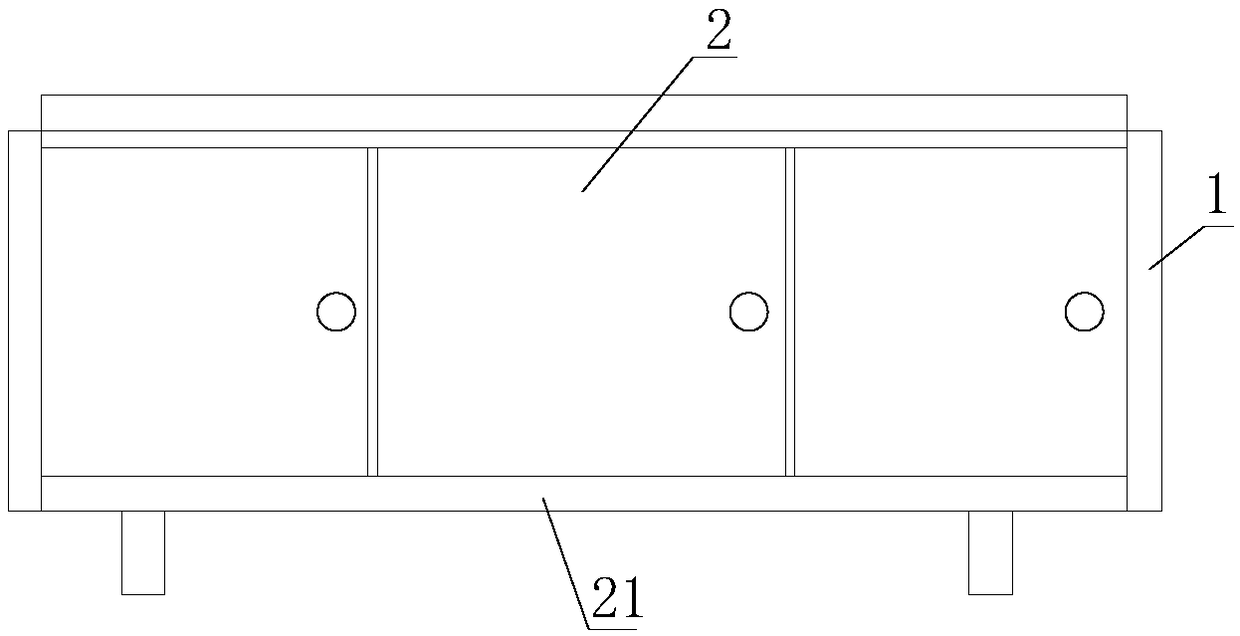

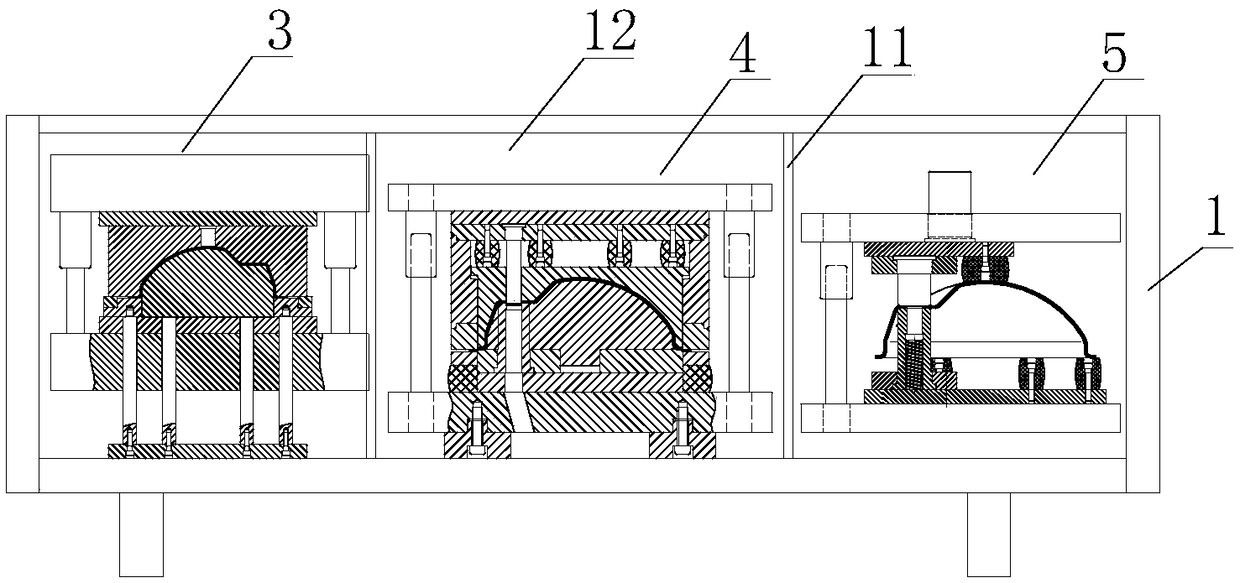

[0042] Such as figure 1 , figure 2 As shown, an integrated processing composite mold set for an automobile drive axle housing cover includes a casing 1, and a plurality of partitions 11 are arranged in the casing 1, and a mold installation cavity 12 is formed between the partitions 11, and the mold The opening of the installation cavity 12 is provided with a dodge door 2, and a guide rail 21 corresponding to the dodge door 2 is provided at the bottom of the casing, and a composite mold for forming an automobile drive axle case cover is respectively provided in each independent mold installation cavity. 3. Composite die 4 for trimming and punching the axle case cover of the automobile drive axle and flattening die 5 for the convex platform of the axle case cover of the automobile drive axle.

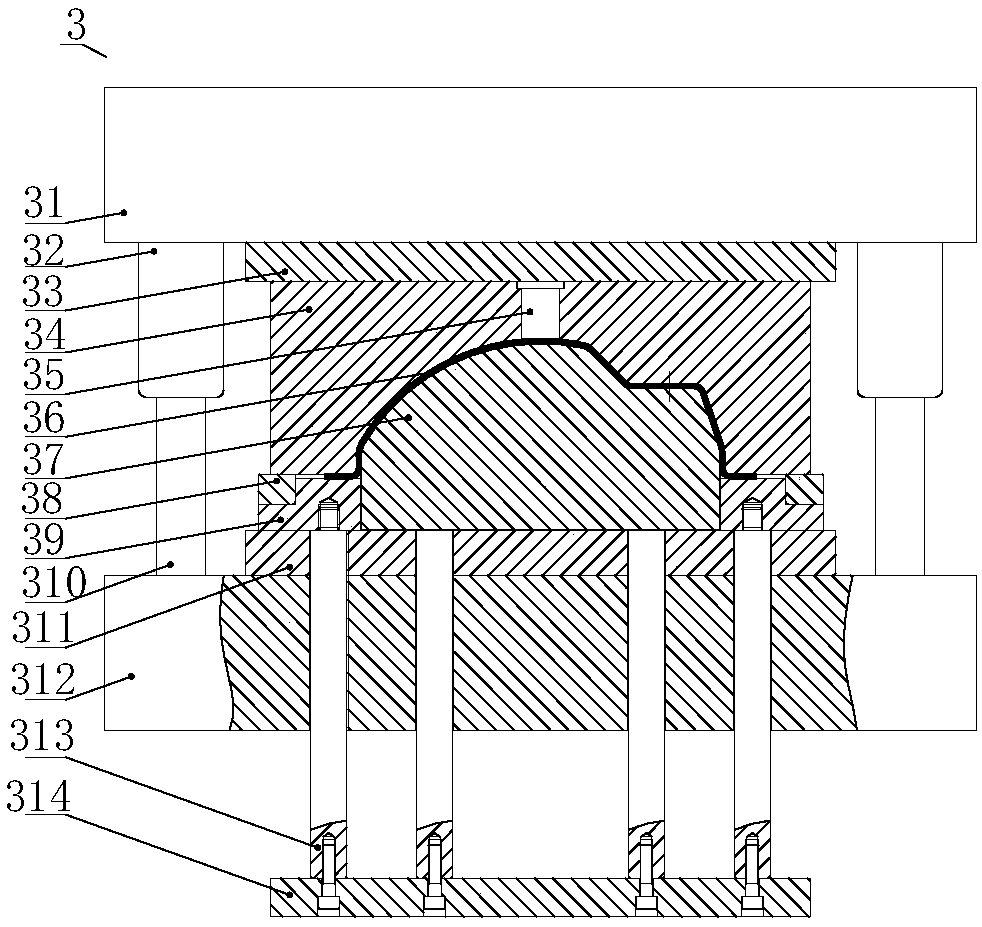

[0043] Among them, such as image 3 , Figure 3a , Figure 3b , Figure 3c As shown, the automobile drive axle axle case cover forming composite mold 3 includes an upper mold and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com