Molding equipment and process of waterproof or antistatic or anti-counterfeiting single corrugated board

A single corrugated cardboard, forming equipment technology, applied in the direction of paper, papermaking, textiles and papermaking, etc., can solve the problems that the forming equipment can not meet the waterproof, anti-counterfeiting or antistatic, can not meet the processing needs and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

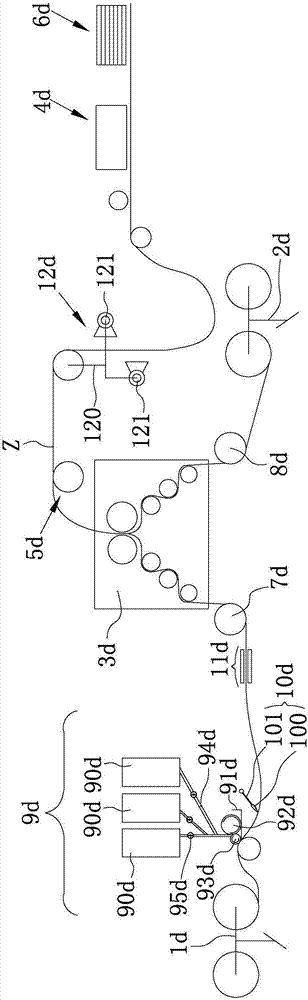

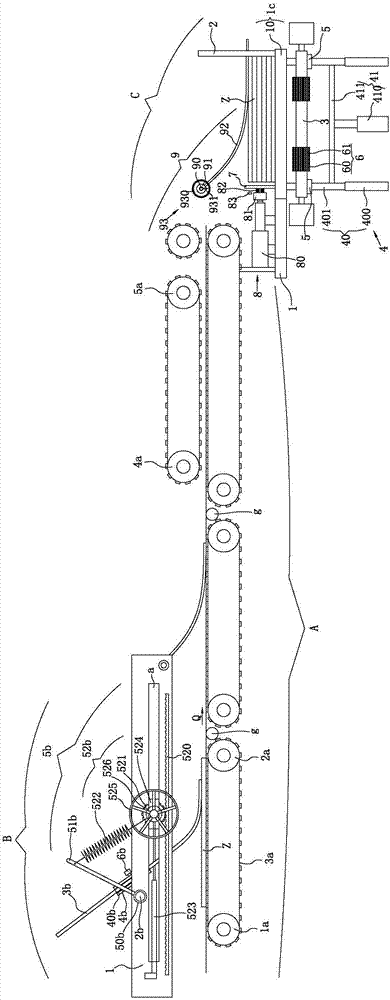

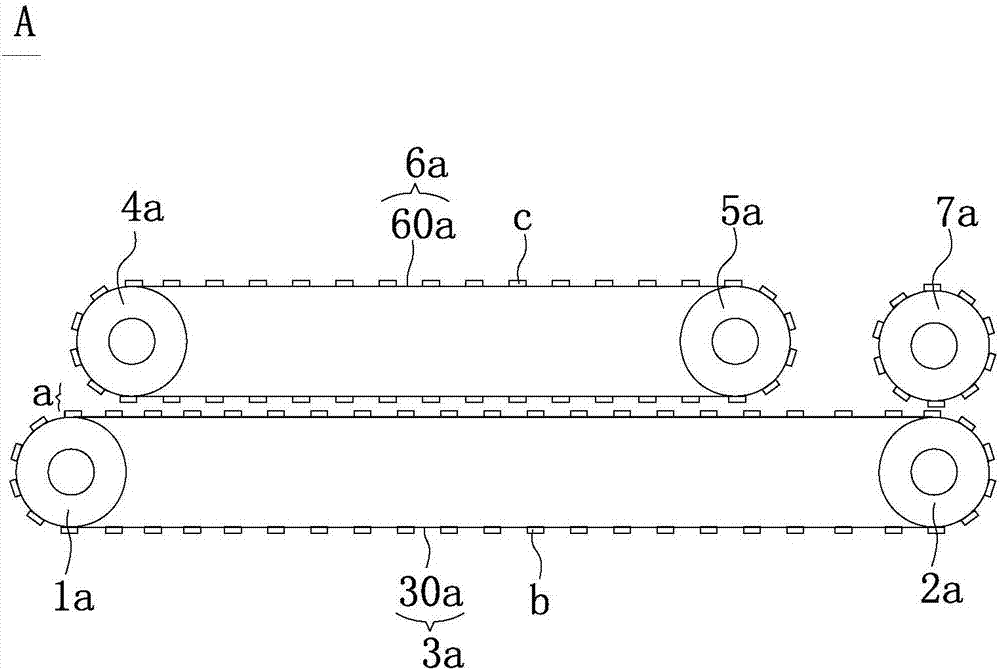

[0073] Such as Figures 1 to 8 As shown, the waterproof or antistatic or anti-counterfeiting single corrugated cardboard forming equipment provided by this embodiment includes a first paper holder 1d and a second paper holder 2d for placing two kinds of paper; The corrugating machine 3d between the second paper frame 2d; Cutting device 4d; The outlet of corrugating machine 3d is connected with the entrance of cutting device 4d to facilitate the conveying device 5d of cardboard transmission; Cardboard collecting machine 6d; The first preheating roller 7d between the frame 1d and the corrugator 3d; the second preheating roller 8d arranged between the second paper frame 2d and the corrugating machine 3d; the first preheating roller 7d and the The paint dipping device 9d between the first paper frame 1a, the leveling device 10d and the ultraviolet irradiation device 11d; the heat supply unit for supplying heat to the first preheating roller 7d and the second preheating roller 8d, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com