Straight type anchor wing rod

A bolt and straight plate technology, which is applied in the installation of bolts, mining equipment, earthwork drilling and mining, etc., can solve problems such as the expansion of the end of the bolt, and achieve good support effects, significant engineering benefits, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

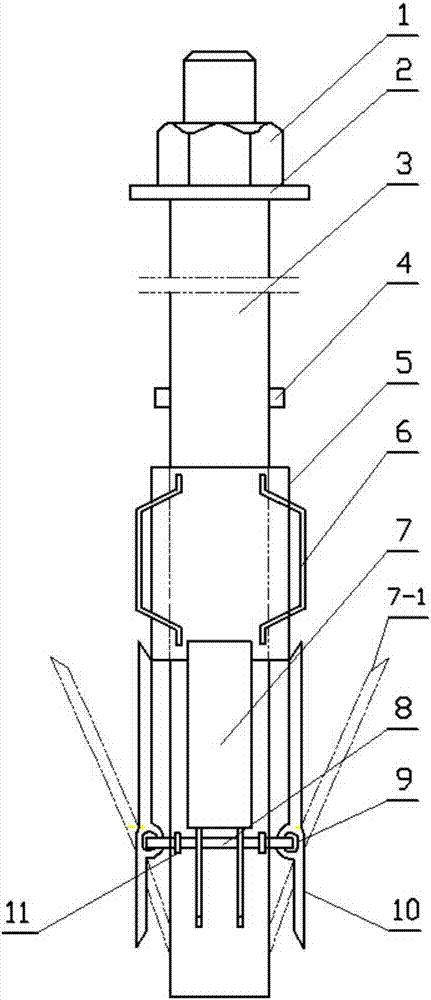

[0011] exist figure 1 Among them, the straight plate type anchor rod, including: anchor nut 1, washer plate 2, anchor rod body 3, stop pin 4, push wing steel pipe 5, positioning rib 6, wing 7, opened wing 7- 1. Reinforcement ring 8, wing ring 9, support column 10, fixed ring 11; the straight plate anchor wing has a cylindrical anchor body 3, and the lower part of the anchor body 3 is covered with a steel ring 8. A fixed fixed ring 11 is evenly arranged on the steel ring 8 and is connected to the wing 7 with the rotatable wing ring 9; the wing 7 is supported in parallel and stands on one side of the anchor rod body 3; The bottom of the wing 7 is a support station column 10, which can limit the opening angle of the upper wing 7; above the wing 7, a movable push-wing steel pipe 5 is installed in the sliding sleeve, and the circumferential surface of the push-wing steel pipe 5 is in the shape of The 120-degree vertical evenly welds the reinforcing bar positioning rib 6; on the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com