Adhesive dust collection system for dust removal in coal mine excavation working face

A technology of excavating working face and gluing, applied in the direction of adhesive, dustproof, mining equipment, etc., can solve the problem of insufficient dust removal effect and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to clearly illustrate the solutions in the present invention, preferred embodiments are given below and detailed descriptions are given in conjunction with the accompanying drawings.

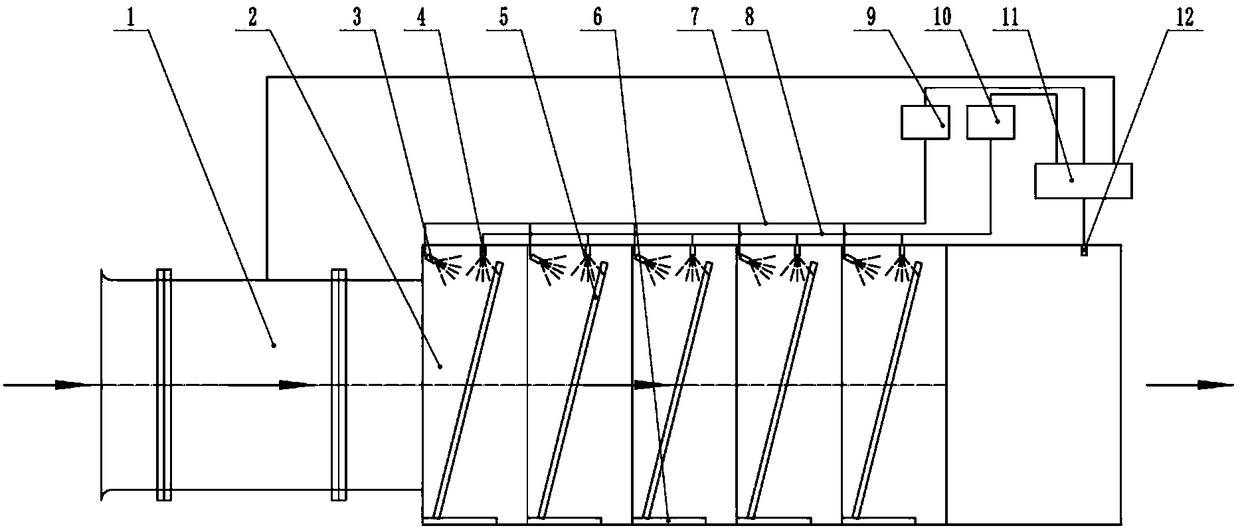

[0021] Depend on figure 1 It can be seen that the adhesive dust collection system for dust removal in coal mine driving face of the present invention includes a ventilation power subsystem 1, an adhesive dust collection subsystem and a control subsystem, and the adhesive dust collection subsystem includes a dust removal chamber 2, a glue spraying device 3. Glue spray pump 9, water spray device 4, water spray pump 10 and dust removal filter grid 5, the dust removal filter grid 5 is evenly coated with dust catch adhesive; the air outlet of the ventilation power subsystem 1 is connected to the The air inlet end of the dust removal chamber 2 is fluidly connected, and the gas outlet end of the dust removal chamber 2 is connected with the atmospheric fluid; The gas outlet is separatel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com