A greenhouse power generation system

A power generation system and greenhouse technology, which is applied in the field of heat pump power generation or heating facility processing, can solve the problems of many factors to be considered, insufficient space utilization, and high renovation costs, so as to speed up the construction cycle, improve heat energy utilization efficiency, and reduce investment costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

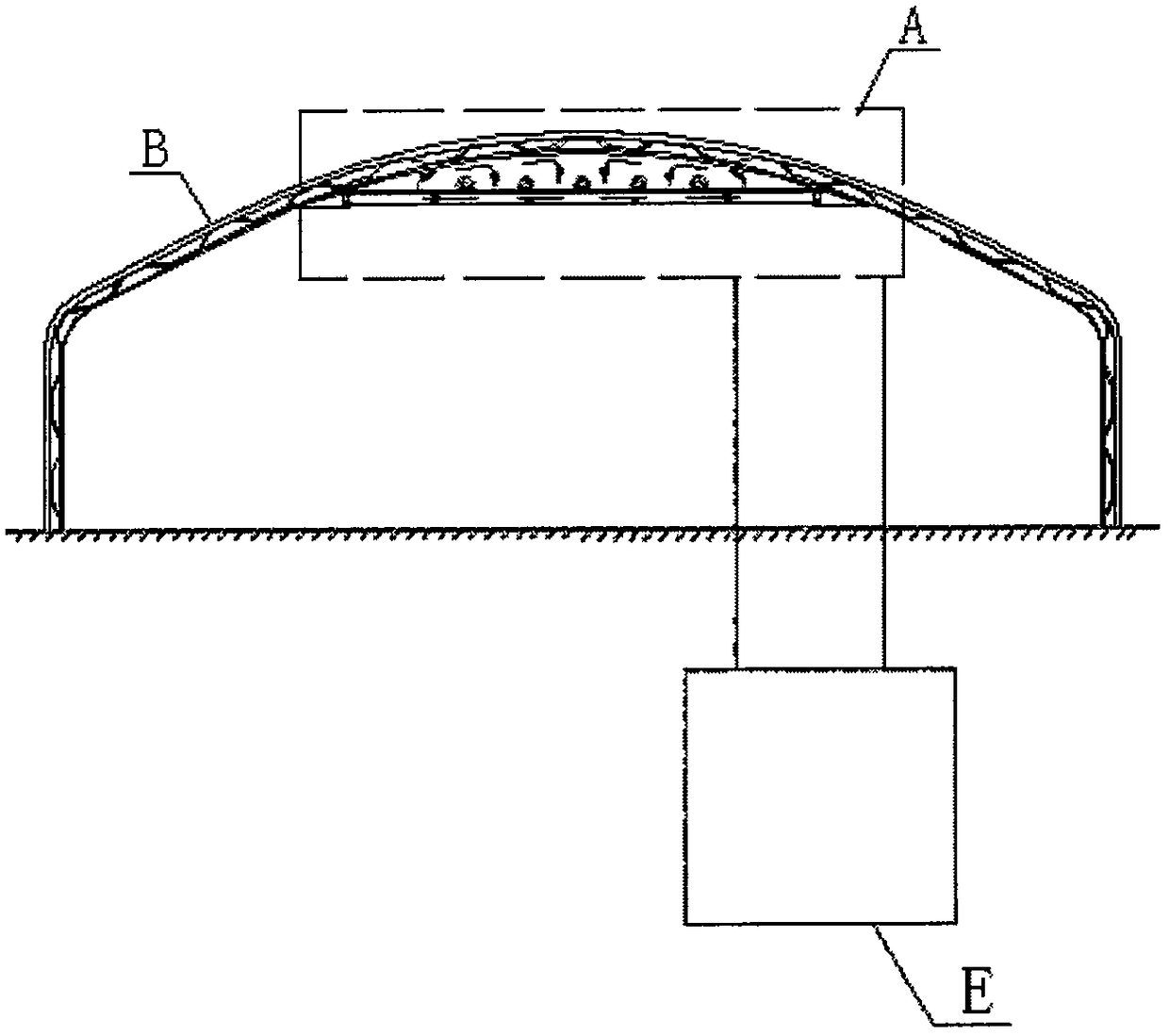

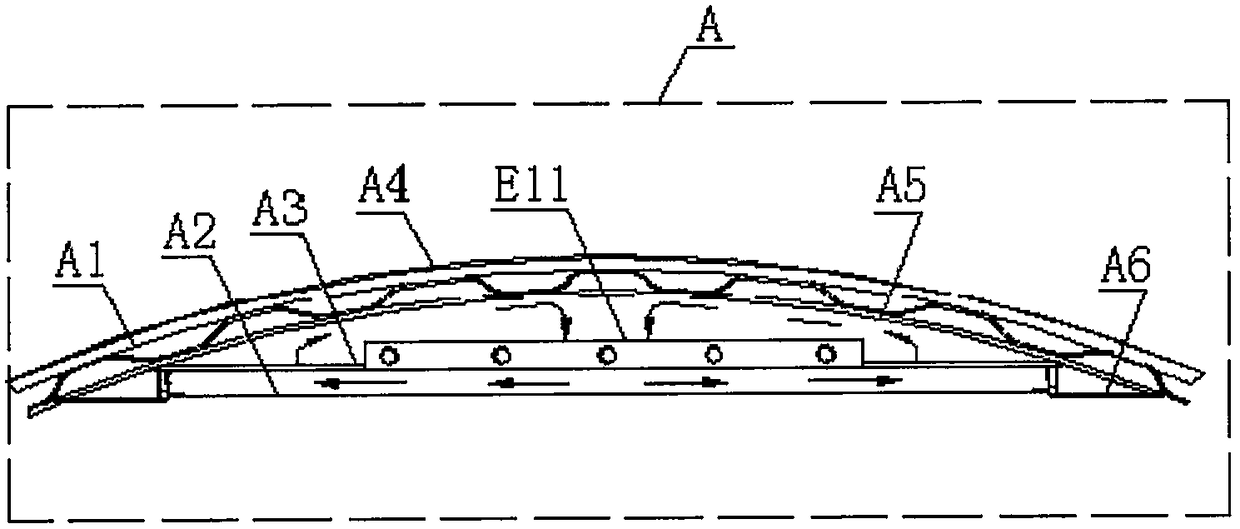

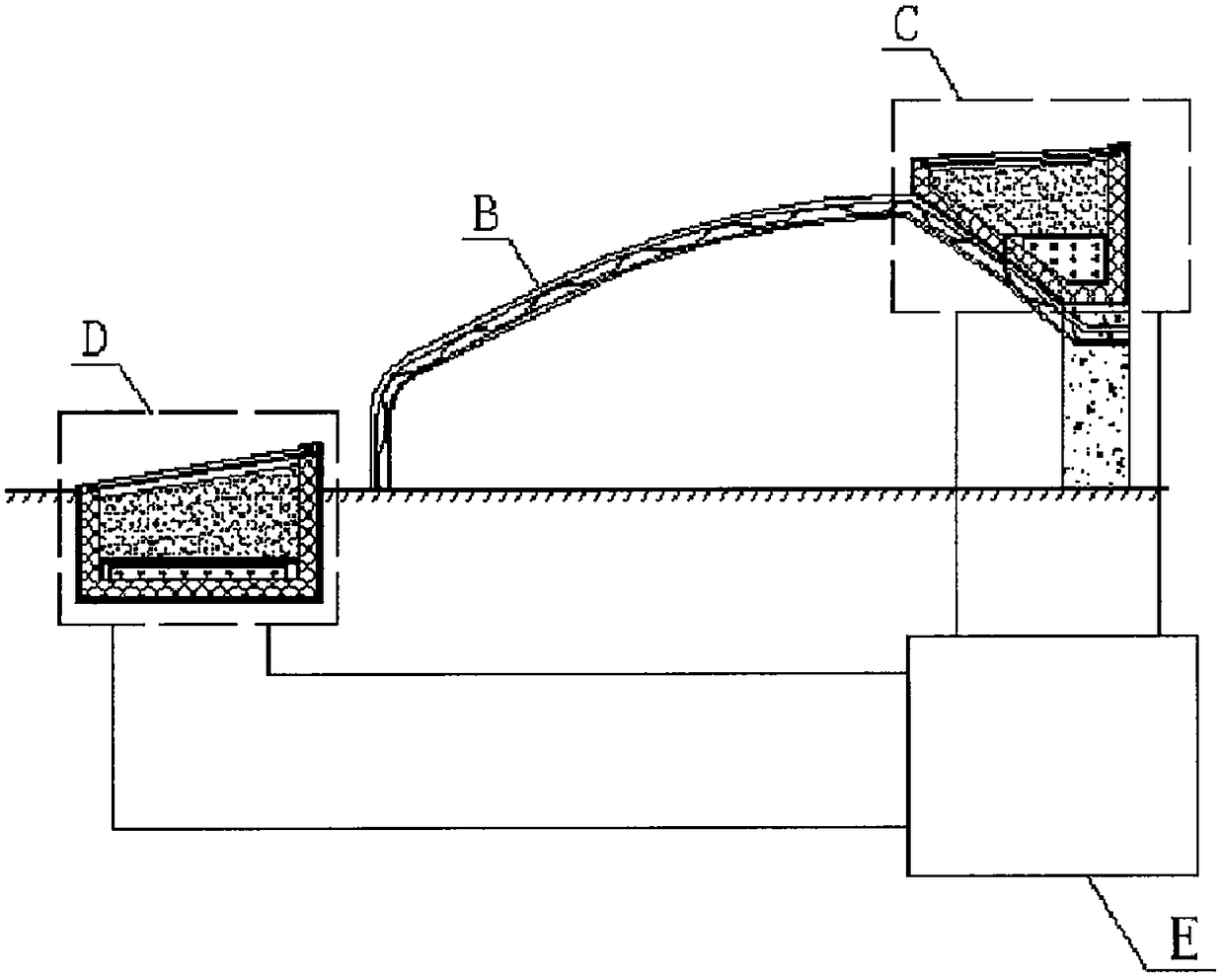

[0029] like Figure 1-2 As shown, the schematic diagram of the embodiment of the diaphragm solar greenhouse power generation system installed on the top of the greenhouse according to the present invention can be seen that it specifically utilizes the existing greenhouse structure to place a single-layer or multi-layer plastic film in the sunlight greenhouse B. A diaphragm type thermal storage device A is formed at the inner top of the inner top, and one or two layers of diversion plastic diaphragms A2 are hoisted on the inner top of the sunshine greenhouse B with slings or slings A6, and the diversion plastic diaphragms A2 and laid on Between the one or two layers of greenhouse plastic film A4 on the skeleton A1 of the greenhouse A, the support bar A3 fixed by the skeleton reinforcement steel bar A5 is installed on the plate or tube heat absorber E11 for the heat pump, thereby using the heat pump of the greenhouse B. The manufactured diaphragm heat storage device A is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com