A Pushing Piston System and Its Application in Pulse Tube Refrigerator

A technology of pulse tube refrigerator and piston, which is applied in refrigerators, refrigeration and liquefaction, compressors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

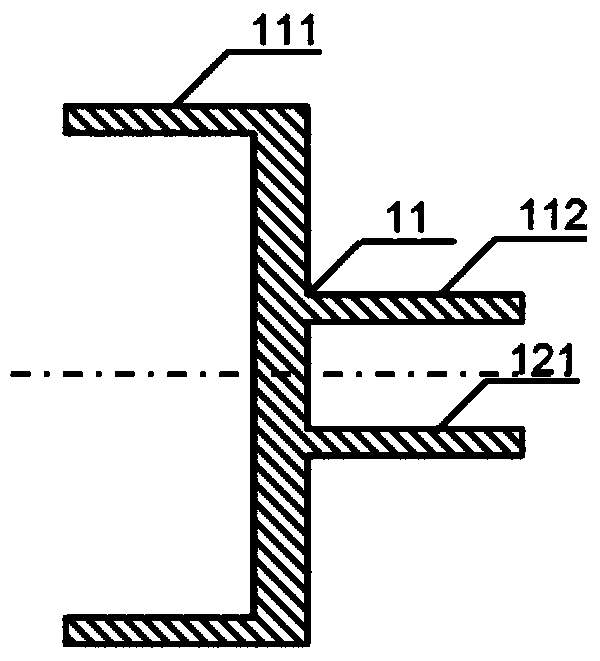

[0061] figure 1 As shown, there is a push piston 111 in the push piston body 11, a push piston rod 112, and a push piston shaft mounting hole 121. Push the piston 111, push the piston rod 112, and push the piston shaft mounting hole 121 to ensure sufficient coaxiality.

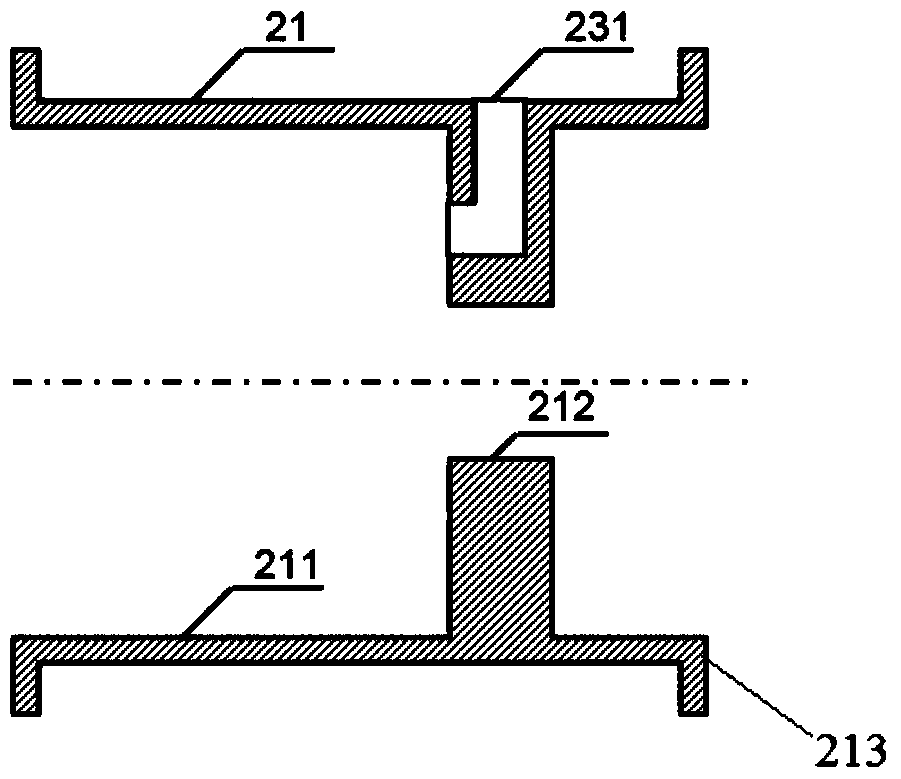

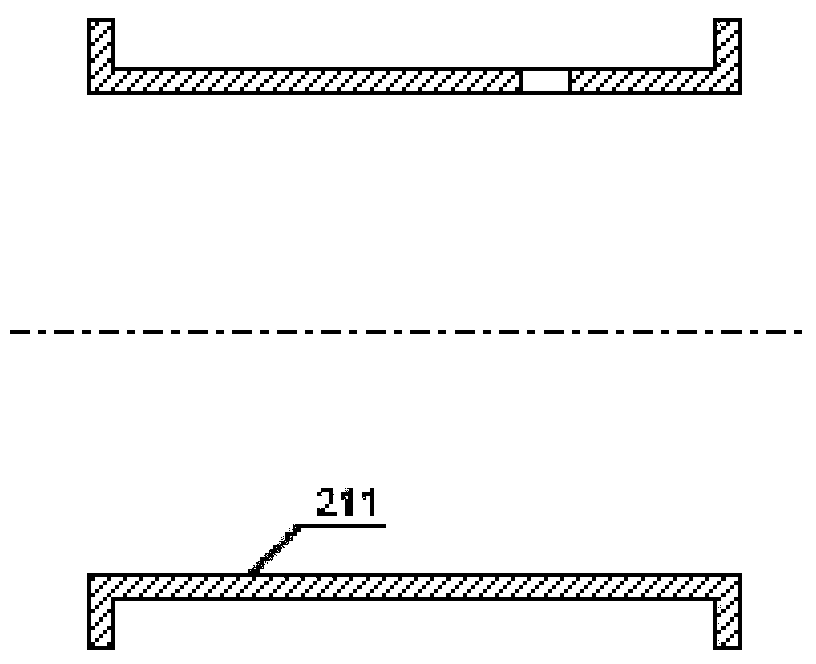

[0062] figure 2 As shown, there is a moving piston cylinder 211 in the moving piston cylinder body 21, a moving piston rod hole 212, a moving piston cylinder installation port 213 and a back cavity port 231. Push the piston cylinder 211, push the piston rod hole 212, and push the piston cylinder installation port 213 to ensure sufficient coaxiality.

[0063] Because in the actual processing process, the push piston cylinder body 21 is processed once, and the coaxiality of the push piston cylinder 211, the push piston rod hole 212 and the push piston cylinder mounting port 213 is also considered, which is difficult. Therefore, the push piston cylinder body 21 can be processed separately, that is, the push p...

Embodiment 2

[0071] Figure 10 It is a multi-stage stepped push piston system, wherein the multi-stage stepped push piston is made hollow and has a pressure balance hole 113, so that the mass of the multi-step stepped push piston can also be used as the volume of the gas storage, such as Figure 8 As shown, the multi-stage step type push piston has a first push piston 141, a second push piston 142 and a third push piston 143, and the second push piston 142, the third push piston 143 and the first push piston 141 keep coaxial as far as possible Spend. Figure 9 Among them, the second push piston cylinder 212 and the third push piston cylinder 213 are respectively arranged between the front end cover 22 of the push piston cylinder block and the second push piston 142 and the third push piston 143, and the two should keep sufficient coaxiality as far as possible. Spend.

[0072] Wherein, the moving piston cylinder 211 (which can be regarded as the first moving piston cylinder in this embodi...

Embodiment 3

[0075] Figure 13 It is a reverse E-type push piston system, wherein the push piston 111 is a reverse E-type piston, such as Figure 11 shown; Figure 12 Push Piston Cylinder Block Front Cover shown for use with Reverse E-Type Pistons; as Figure 13 As shown, in the anti-E type push piston system, a first push piston front chamber 221a and a second push piston front chamber 221b are provided, and the first push piston front chamber 221a has a first push piston front cavity port 232a, and the second push piston front chamber The front chamber 221b has a second push piston front chamber port 232b. All the other structures are the same as in Example 1.

[0076] Figure 13-1 It is a structural schematic diagram of the reverse E-type moving piston system used in a multi-stage pulse tube refrigerator in this embodiment. The freezing part 40 is composed of a cooler 41, a first-stage regenerator 42a, a first-stage cold head 43a and a first-stage pulse tube 44a; and the first-stag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com