Electric power glass wall hard matter cleaning device

A technology for cleaning devices and glass walls, which can be applied to cleaning machines, cleaning equipment, carpet cleaning, etc., and can solve problems such as not being able to adapt to walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

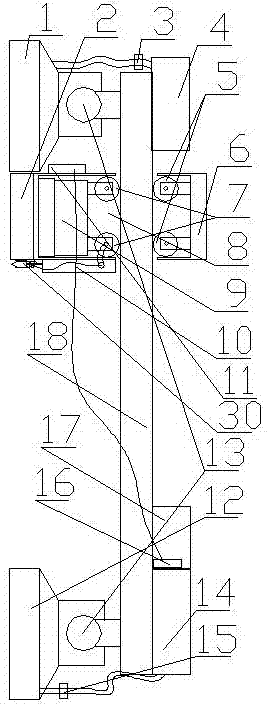

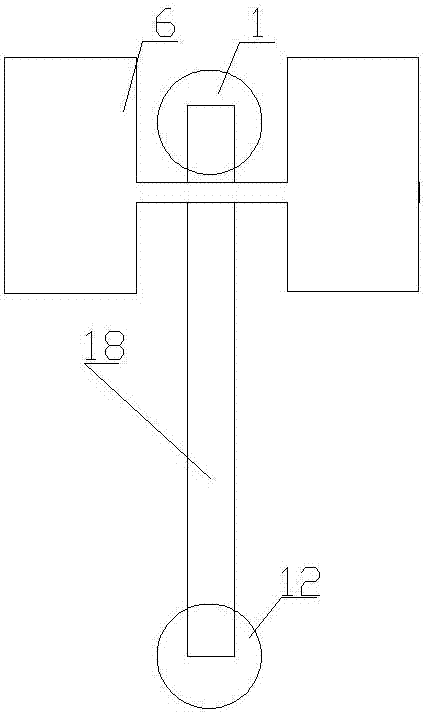

[0031] An electric glass wall hard object cleaning device, including a slide rail and a brush body 6 arranged on the slide rail 18, the brush body is provided with bristles 2, and an upper suction cup 1 is arranged on the inner upper part of the slide rail, and the slide rail The inner lower part is provided with a lower suction cup 12, and the brush body is provided with a drive mechanism that drives the brush body to move up and down along the slide rail. The upper part of the slide rail is provided with an upper air pump 4 connected with the upper suction cup. The lower air pump 14 connected to the lower suction cup, the brush body is provided with an elastic foreign body cleaning mechanism for clearing hard objects on the glass wall.

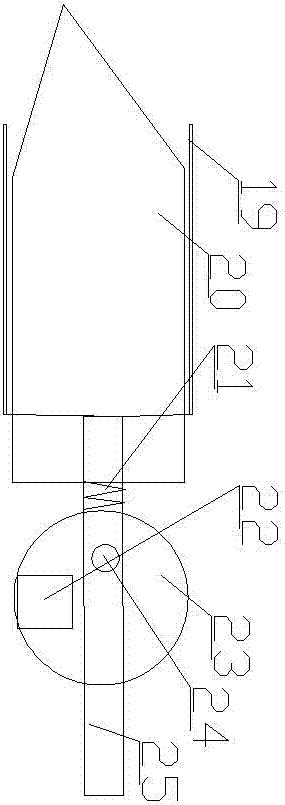

[0032] When the bristles are pressed on the glass, the cutter body does not touch the glass from head to toe. At this time, under the joint action of the eccentric wheel, the distance between the cutter body and the glass is 0.5 mm. The cutt...

Embodiment 2

[0042] An electric glass wall hard object cleaning device, including a slide rail and a brush body 6 arranged on the slide rail, the brush body is provided with bristles 2, an upper suction cup 1 is arranged on the inner upper part of the slide rail, and the inner side of the slide rail The bottom is provided with a lower suction cup 12, and the brush body is provided with a driving mechanism that drives the brush body to move up and down along the slide rail. The upper part of the slide rail is provided with an upper air pump 4 connected with the upper suction cup. The lower air pump 14 that suction cup is connected.

[0043] The upper suction cup is connected with the slide rail through the Vientiane ball head assembly 13 .

[0044] The lower suction cup is connected with the slide rail through a Vientiane ball joint assembly 13 .

[0045] The air guide pipe of the upper air pump 4 and the upper suction cup is provided with an upper electromagnetic valve 3 .

[0046] The a...

Embodiment 3

[0053] An electric glass wall hard object cleaning device, including a slide rail and a brush body 6 arranged on the slide rail, the brush body is provided with bristles 2, an upper suction cup 1 is arranged on the inner upper part of the slide rail, and the inner side of the slide rail The bottom is provided with a lower suction cup 12, and the brush body is provided with a driving mechanism that drives the brush body to move up and down along the slide rail. The upper part of the slide rail is provided with an upper air pump 4 connected with the upper suction cup. The lower air pump 14 connected to the suction cup, the brush body is provided with an elastic foreign matter cleaning mechanism 30 for clearing hard objects on the glass wall.

[0054] When the bristles are pressed on the glass, the cutter body does not touch the glass from head to toe. At this time, under the joint action of the eccentric wheel, the distance between the cutter body and the glass is 0.5 mm. The cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com