Pharmaceutical preparation tank with cleaning and height-adjusting functions

A technology of height adjustment and batching tank, which is applied to mixers with rotating stirring devices, mixer accessories, transportation and packaging, etc. It can solve the problem of affecting the batching effect of lipid materials, unfavorable use by people of different heights, and the height of batching tanks cannot be adjusted, etc. problems, to achieve the effect of saving manpower, improving the effect of ingredients, and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

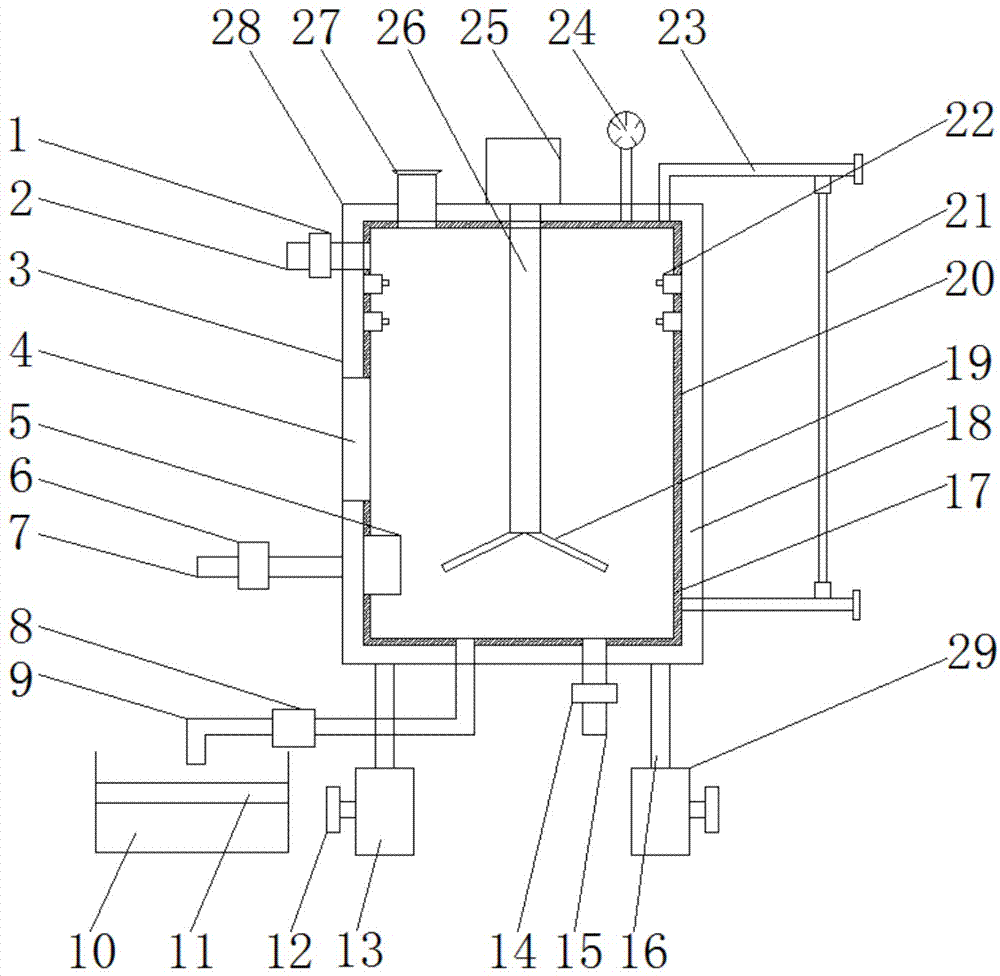

[0014] combine figure 1 , in an embodiment of the present invention, a pharmaceutical batching tank with cleaning and height adjustment functions, including a first water inlet pipe 2, a second water inlet pipe 7, a water outlet pipe 9, a waste liquid collection tank 10, a discharge pipe 15, and a nozzle 22 , drainage tube 23, hydraulic gauge 24, motor 25, feed pipe 27, tank body 28 and telescopic rod 29, two telescopic rods 29 of the same specification are symmetrically installed at both ends of the bottom of the tank body 28, and the telescopic rod 29 includes a tube Body 13, bolt 12 and rod body 16, rod body 16 is slidingly connected in the cylinder body 13, and the cylinder body 13 is provided with a threaded through hole threaded with the bolt 12, and the bolt 12 rotates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com