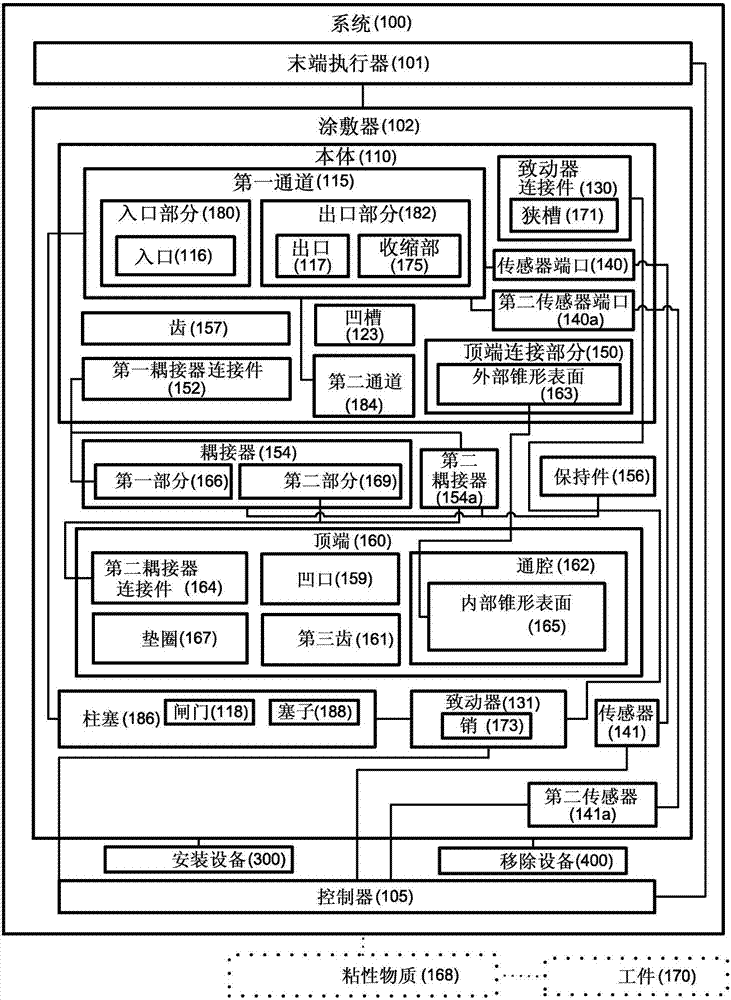

Applicators For Delivering Glutinous Substance To Workpiece From End-Effector And Associated Apparatuses, Systems, And Methods

A technology for end effectors and viscous substances, applied in the direction of coatings, devices for applying liquid to surfaces, brushes, etc., can solve time-consuming and difficult problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 26

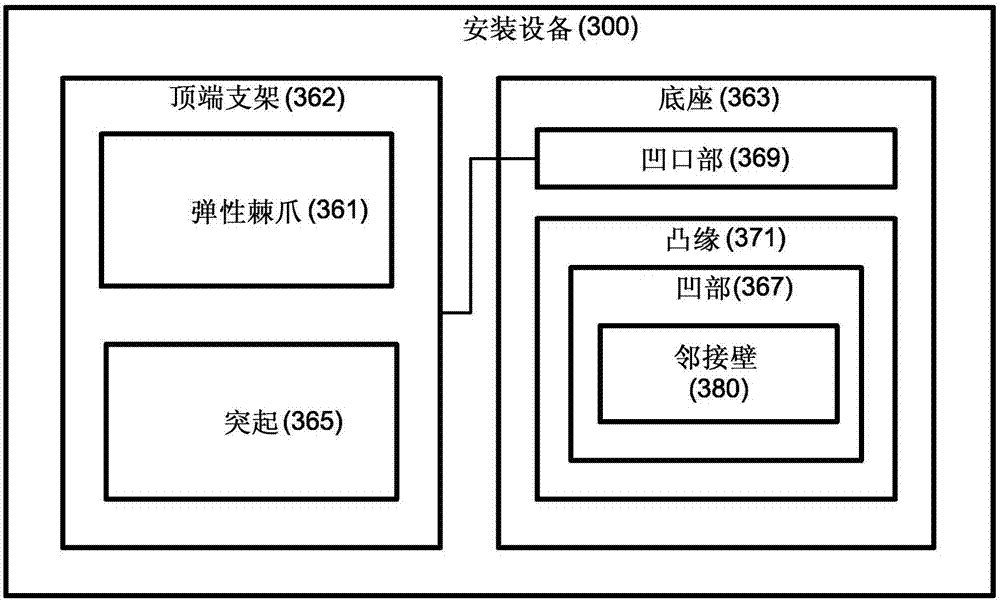

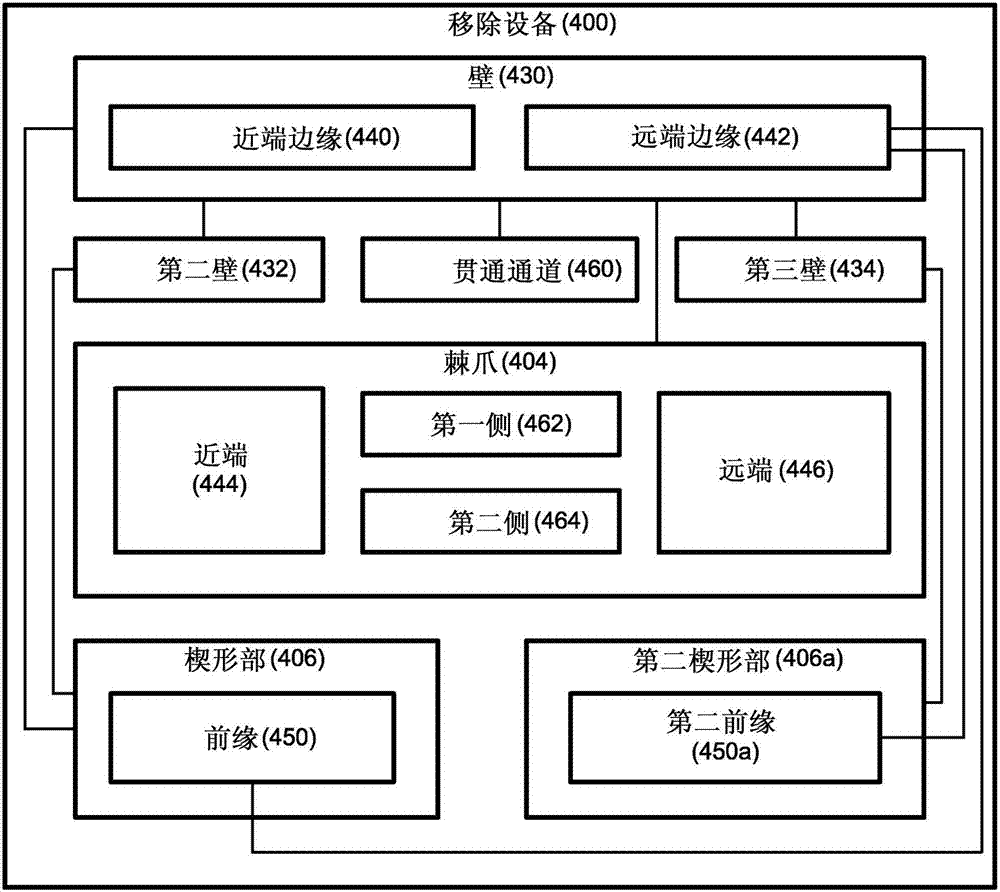

[0123]Tip 160 configured to releasably attach to body 110 facilitates interchangeability of the tip with body 110 . For example, differently sized and shaped tips 160 each configured to differently apply viscous substance 168 to workpiece 170 may be releasably attachable to body 110 in response to application constraints associated with workpiece 170 . This interchangeability of tip 160 facilitates the ability to utilize one body 110 to differently apply adhesive 168 to workpiece 170 . Using one body 110 and multiple interchangeable tips 160 to differentially apply adhesive 168 to workpieces facilitates reduced manufacturing delays and costs. For example, body 110 may be made of a different (eg, more expensive and easier to manufacture) material than tip 160 . Coupler 154 interlocks with tip 160 and body 110 such that coupler 154 has up to three degrees of freedom relative to tip 160 and body 110 to facilitate securing tip 160 to body 110 . Additionally, the coupler 154 allo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com