Forging equipment

A kind of equipment and forging technology, which is applied in the direction of metal processing equipment, forging presses, forging presses, etc., can solve problems such as connection defects between briquetting blocks and hydraulic rods, briquetting blocks falling off, and briquetting blocks tilting, so as to avoid vibration disturbance and improve shock absorption Efficiency, the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

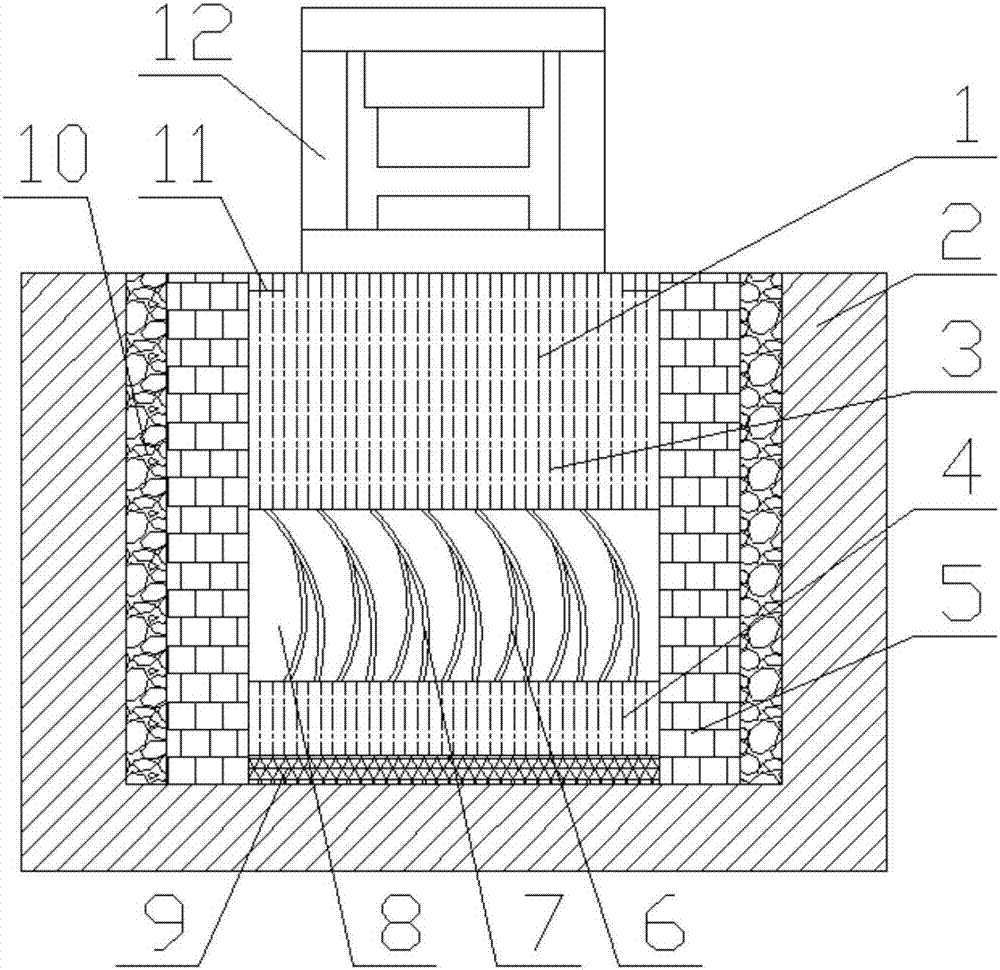

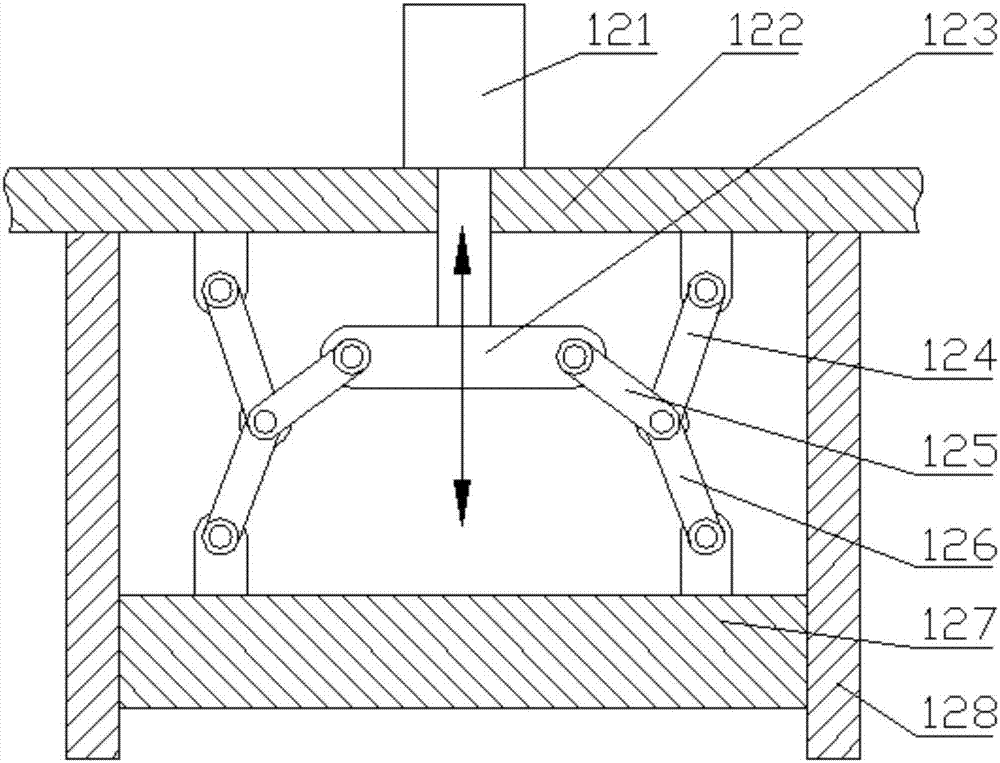

[0034] A shock-absorbing device for forging, comprising a groove 1 excavated in the ground, a concrete layer 2 is arranged around and on the bottom of the groove 1, and an upper pillar 3 and a lower pillar 4 are arranged in the center of the groove 1. Surrounding the upper pillar 3 and the lower pillar 4 is provided with an enclosure 5, the enclosure 5 can be a brick wall structure, under the lower pillar 4 is padded with a hard rubber pad 9, the forging equipment 12 is fixed on the upper pillar 3; A sandstone layer 10 is filled between the outer layer and the side wall of the groove 1. Multiple sets of shock-absorbing structures are arranged between the upper pillar 3 and the lower pillar 4, and the multiple sets of shock-absorbing devices are uniformly distributed along the cross-sectional direction of the groove 1, which is realized. The forging device 12 includes a frame 122, a hydraulic cylinder 121 arranged on the frame 122, and guide rails 128 arranged on both sides of t...

Embodiment 2

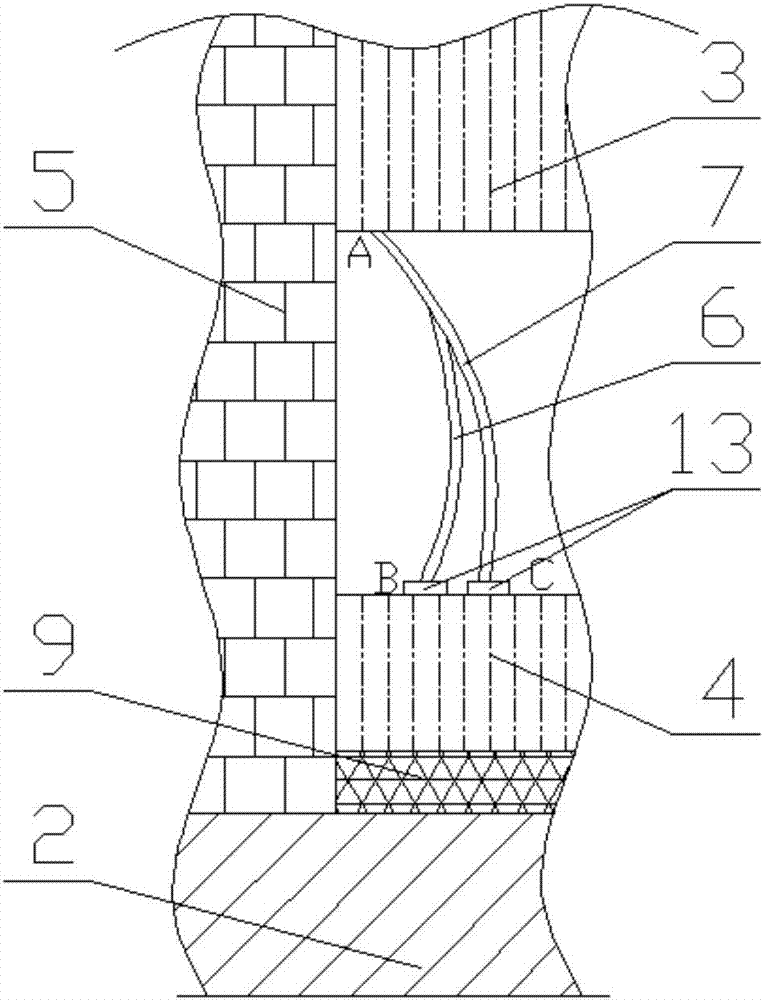

[0036] On the basis of the first embodiment, the damping structure includes a main damping plate 7. The two ends of the main damping plate 7 are respectively connected with the upper pillar 3 and the lower column 4, and the main damping plate 7 is also connected with auxiliary damping The other end of the plate 6 and the auxiliary damping plate 6 is connected with the upper pillar 3 or the lower pillar 4. When the forging equipment 12 exerts downward force, the main damping plate 7 and the auxiliary damping plate 6 will be squeezed, and the main damping plate 7 and the auxiliary damping plate 6 will be deformed, thereby achieving the purpose of damping and buffering.

Embodiment 3

[0038] On the basis of the second embodiment, the main damping plate 7 is set as an arc-shaped main damping plate 7, the auxiliary damping plate 6 is set as an arc-shaped auxiliary damping plate 6, and the convex direction of the main damping plate 7 Consistent with the convex direction of the auxiliary damping plate 6, the main damping plate 7 and the auxiliary damping plate 6 are connected to form a herringbone structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com