Conveyor

A technology of conveying device and running body, which is applied in conveyors, mechanical conveyors, transportation and packaging, etc., and can solve the problem that the screw drive method is not known

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

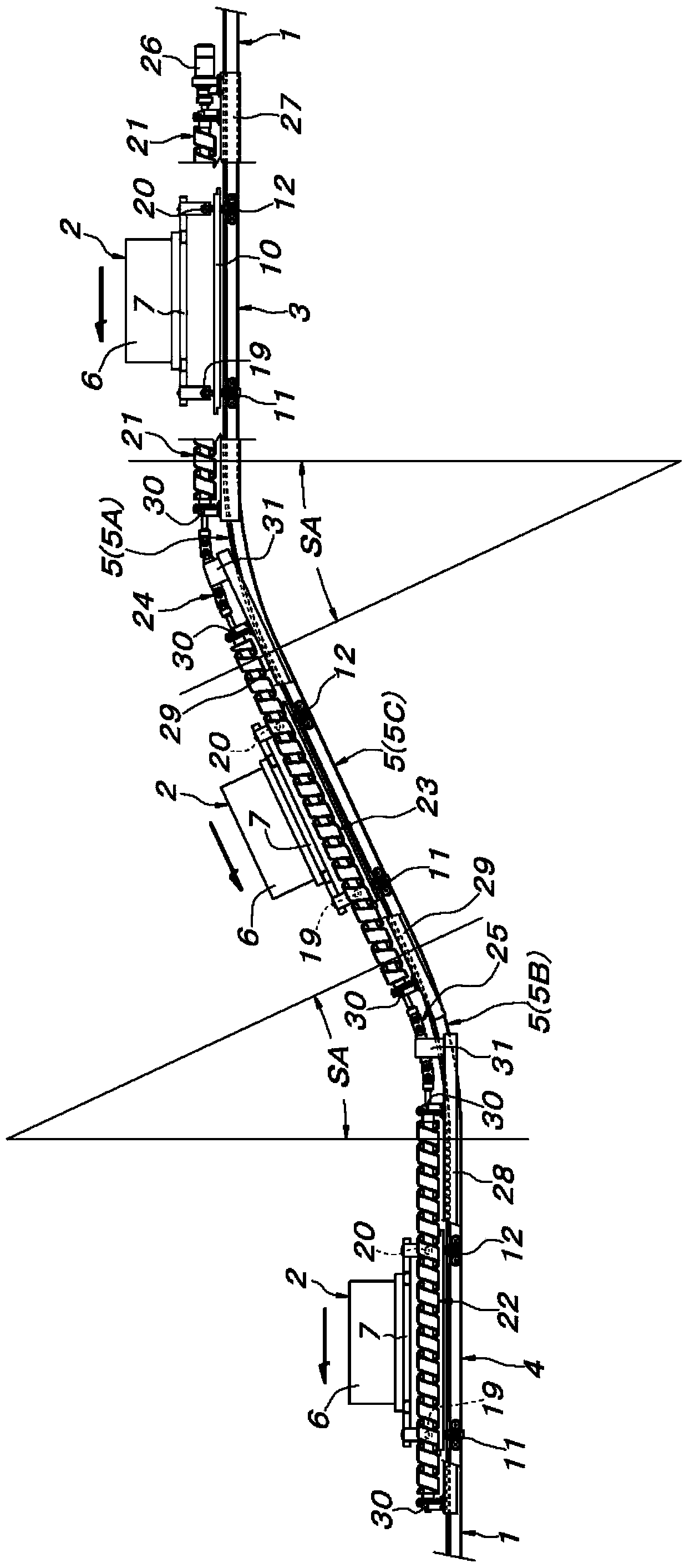

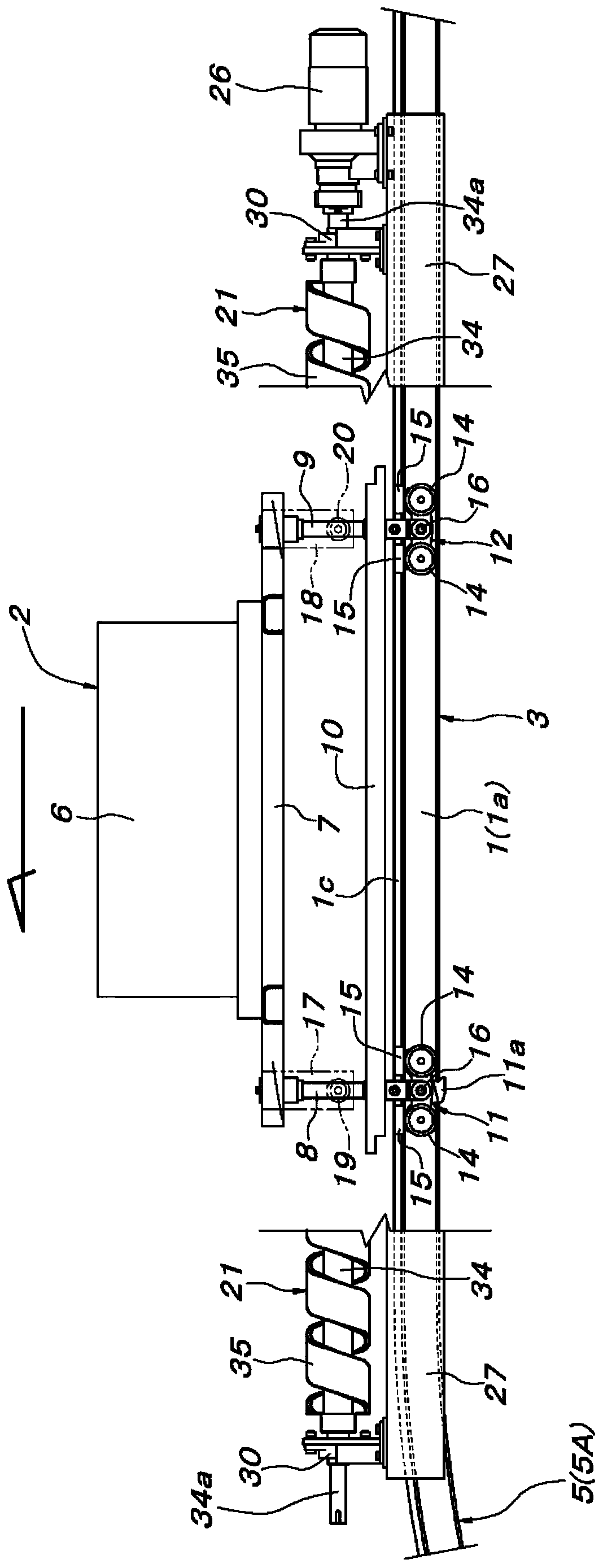

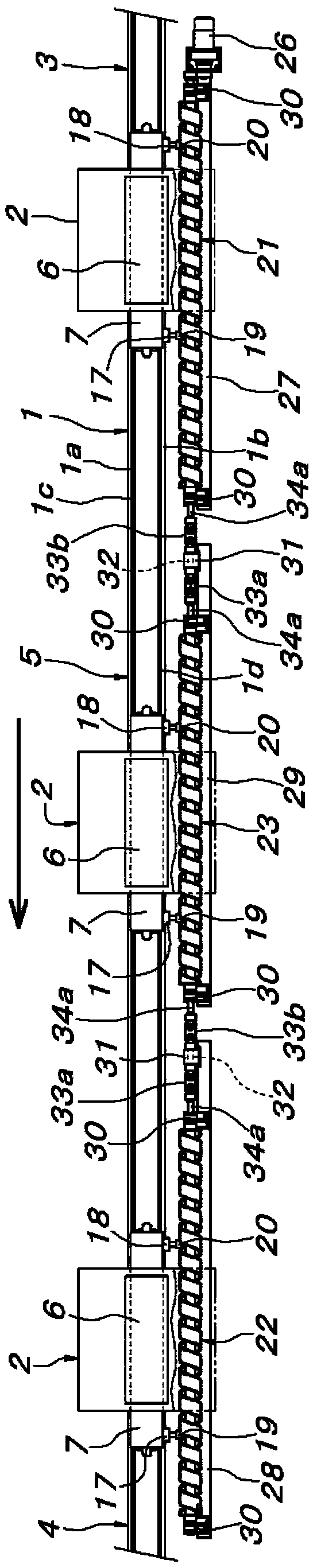

[0056] based on Figure 1~6 Referring to the first embodiment, an inclined path portion 5 connecting the upper horizontal path portion 3 and the lower horizontal path portion 4 is provided on the traveling path of the transport traveling body 2 constituted by the guide rail 1 . In this embodiment, the transport running body 2 travels from the upper horizontal path portion 3 to the lower horizontal path portion 4 via the inclined path portion 5 . The traveling body 2 for conveying is made up of the following components: a long main body 7 in the forward and backward travel direction, and the main body 7 is provided with a conveyed object supporting part 6 on the upper side; The pillar members 8 and 9 are connected to be vertically downward from the central position in the width direction of the front and rear ends of the main body 7; the load rod 10 for friction driving is mounted on the front and rear pair of supporting pillar members. 8, 9 in the vicinity of the lower end an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com