Automatic pressing structure of carton cover

A technology for pressing structures and cartons, applied in packaging and other directions, can solve the problems of inability to improve production efficiency, inability to realize automatic packaging, and high production costs, and achieve the effects of reducing labor, reliable and durable structure, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

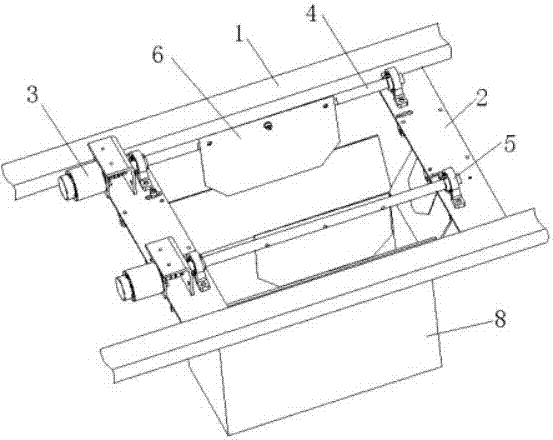

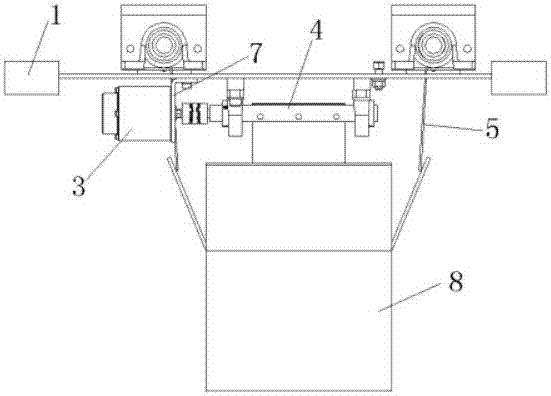

[0021] Such as Figure 1-2 As shown, the automatic compression structure of the carton cover includes two parallel beams 1, a mounting plate 2 is fixedly connected between the two beams 1, and a compression structure is installed above and below the mounting plate 2. , the pressing structure includes a driving motor 3 fixed on the mounting plate 2, the output shaft of the driving motor 3 is connected with a rotating shaft 4, and the two ends of the rotating shaft 4 are connected with bearing housings 5, and the rotating shaft 4 is fixed A compression plate 5 is connected, and the number of the compression structures is four and surrounds a rectangle.

[0022] Specifically, one side of the pressing plate 5 is fixedly connected to the rotating shaft 4 , and the other side is provided with chamfers, so that the carton surface will not be scratched when pressing the carton cover.

[0023] Specifically, the pressing plates 5 do not interfere with each other, and the four driving m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com