Method for manufacturing cutlery

A manufacturing method and tableware technology, which is applied in the field of tableware manufacturing, can solve the problems of increased process, separate process, and increased cost, and achieve the effects of improving surface quality, preventing deformation, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, preferred embodiments of the present invention are described in detail with reference to the accompanying drawings. In order to enable those with basic knowledge in the technical field of the present invention to implement the present invention in detail, this description should not limit the present invention technical thinking and scope. Also, the terms used herein to define relative positions such as front and rear, left and right, up and down, inside and outside are based on the drawings.

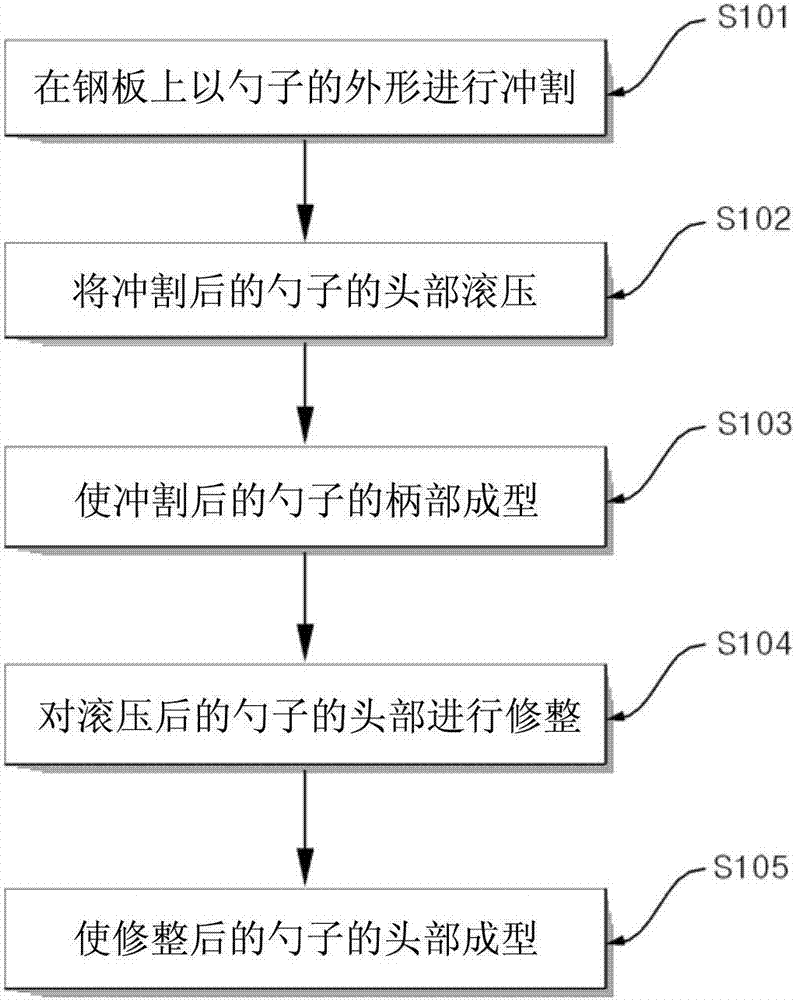

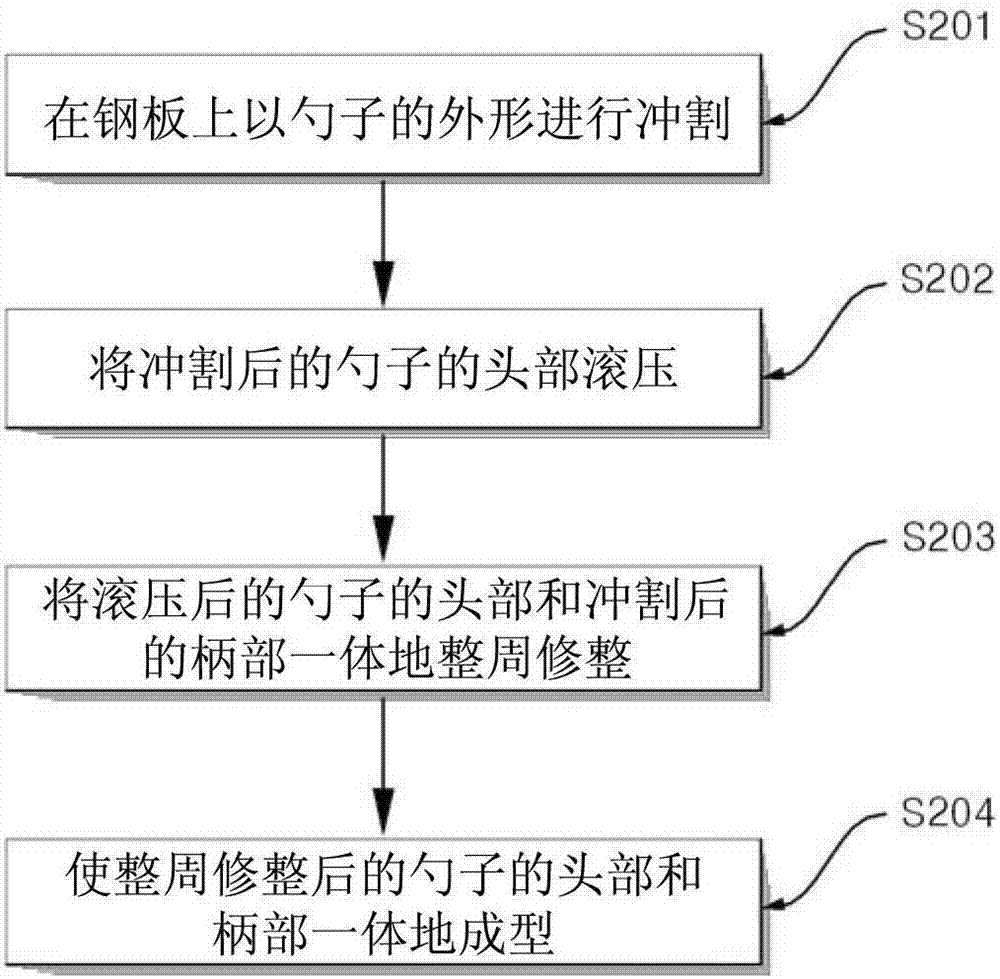

[0044] figure 2 It is a figure showing the process of manufacturing a spoon as a kind of tableware by a method according to an embodiment of the present invention, image 3 is shown in use figure 2 This is a diagram showing an example of an integrated mold used in the molding process when manufacturing spoons using this method.

[0045] The manufacturing method of the spoon according to the embodiment of the present invention is by figure 2 The procedure shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com