Method for producing naked barley puffed and crisp food by means of hot air-microwave combined drying

A combined drying and microwave puffing technology, which is applied in the field of food processing, can solve the problems of high water content, unsuitable storage, and short shelf life of Yuanmai sweet unstrained spirits, and achieve the effects of shortening drying time, significant economic and social benefits, and increasing sweet taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

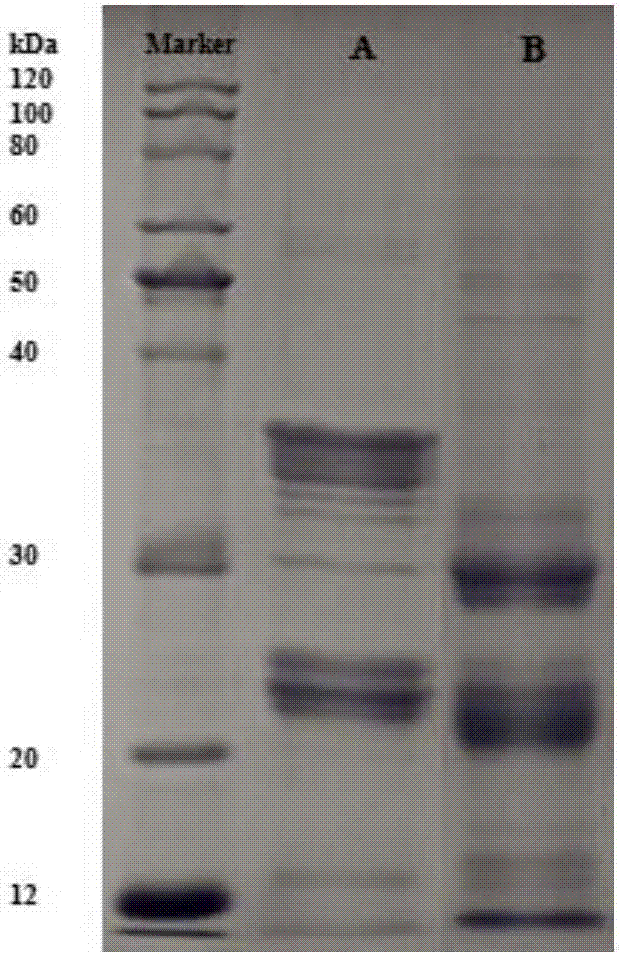

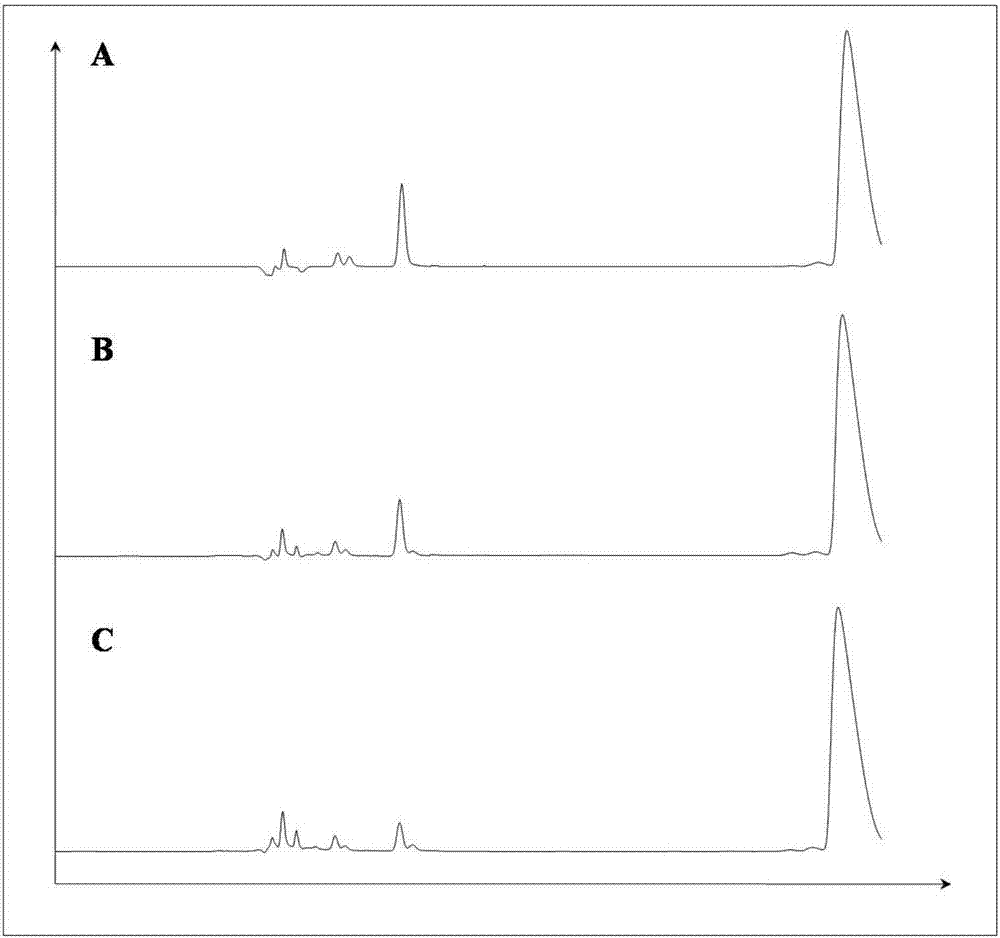

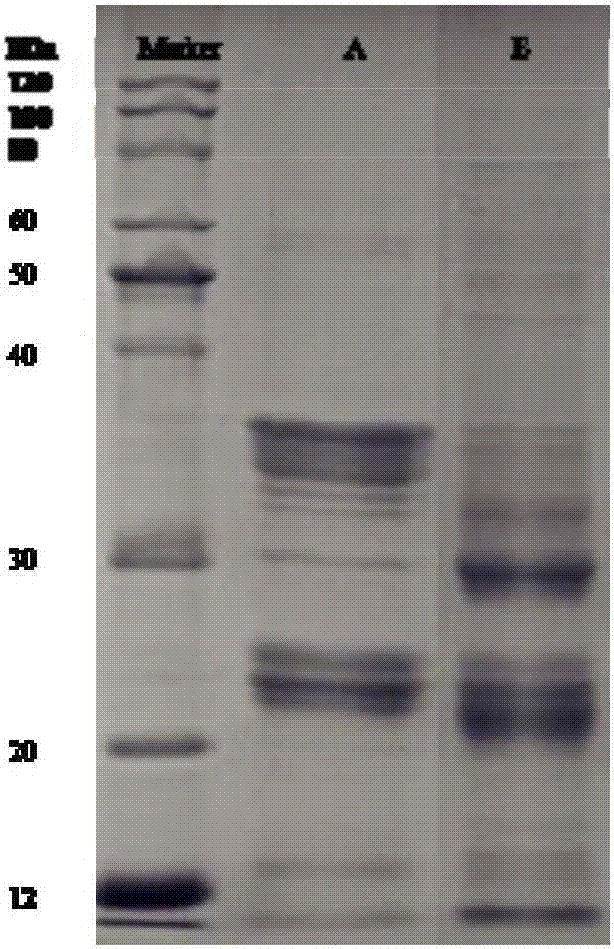

Embodiment 1

[0035]Select and remove the impurities, shriveled grains and bad grains in the barley, wash and dry, add 5 times of water to it, soak at 22°C for 6 hours, drain and set aside. Add water of the same quality into the steamer, place gauze on the steaming sheet, spread the soaked barley on it, and cook at 90-105°C for 15 minutes at a power of 1500W. Spot Rhizopus oryzae on a PDA plate and place it upside down in a 25°C incubator for cultivation. When obvious white mycelium grows, pick a small amount of mycelium and transfer it to a fresh PDA plate for activation until the mycelium grows vigorously. And when a large amount of gray-brown spores visible to the naked eye are produced, scrape off the mycelia with a sterile coating stick, add a very small amount of water, and fully grind into a spore homogenate in a mortar. The mass concentration of the spores in the homogenate is 10 7 -10 9 individual / mL. Put the washed rice into an electric rice cooker, add 3 times of water, cook fo...

Embodiment 2

[0047] Select and remove the impurities, shriveled grains and bad grains in the barley, wash and dry, add 2 times of water to it, soak at 26°C for 10 hours, drain and set aside. Add water of equal quality into the steamer, place gauze on the steaming sheet, spread the soaked barley on it, and steam for 20 minutes at a power of 1200W. Spot Rhizopus oryzae on a PDA plate and place it upside down in a 25°C incubator for cultivation. When obvious white mycelium grows, pick a small amount of mycelium and transfer it to a fresh PDA plate for activation until the mycelium grows vigorously. And when a large amount of gray-brown spores visible to the naked eye are produced, scrape off the mycelia with a sterile coating stick, add a very small amount of water, and fully grind into a spore homogenate in a mortar. The mass concentration of the spores in the homogenate is 10 7 -10 9 individual / mL. Put the washed rice into an electric rice cooker, add 4 times of water, cook for 30 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com