Processing method for heating non-combusted cigarette

A heat-not-burn, processing method technology, which is applied to tobacco, tobacco processing, cigarette manufacturing and other directions, can solve the problems of small smoke volume, difficult volatilization of the active ingredients of cut tobacco, poor smoking quality, etc., so as to improve porosity, reduce Resistance and the effect of shredded tobacco on the adsorption of flue gas and improving the passing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

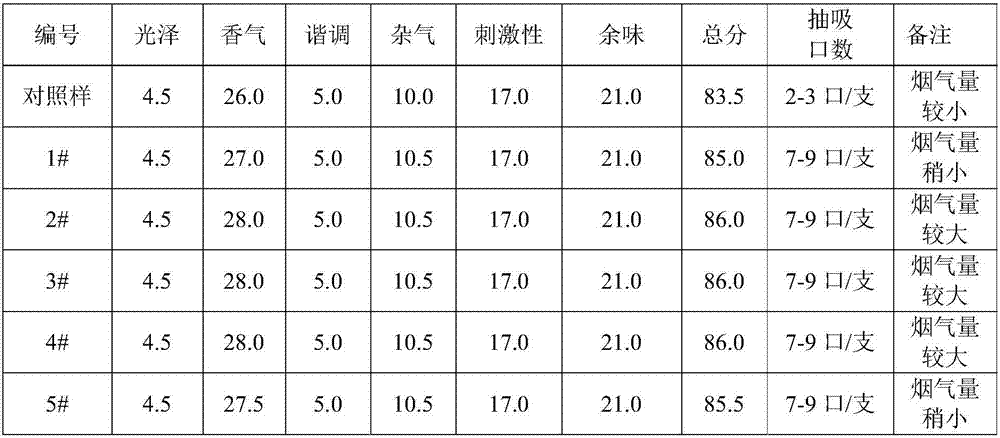

[0042] Quantitative 100.0±5.0g / m 2 , The papermaking reconstituted tobacco leaves with a thickness of 0.22±0.02mm are cut into multiple long shredded tobaccos in one direction by a cutting device. Close up into an orderly arranged shredded tobacco rod, and then wrap the forming paper to form a cylindrical tobacco rod with orderly arranged shredded tobacco. Cut the tobacco rod according to the length specification of 100.0mm, and then cut the cylindrical tobacco rod with a length of 100.0mm according to the length of 10.0mm, and then connect it with the cigarette filter tip to form the 1# sample of the heat-not-burn cigarette.

[0043] Set the widths of the strips of shredded tobacco to 0.8mm, 1.0mm, 1.2mm, and 1.5mm respectively, repeat the above-mentioned process, and obtain 4 heat-not-burn cigarettes with different widths of the strips of shredded tobacco, 2#, 3#, 4#, 5# sample. In addition, using the conventional cigarette technology, the reconstituted tobacco leaves of t...

Embodiment 2

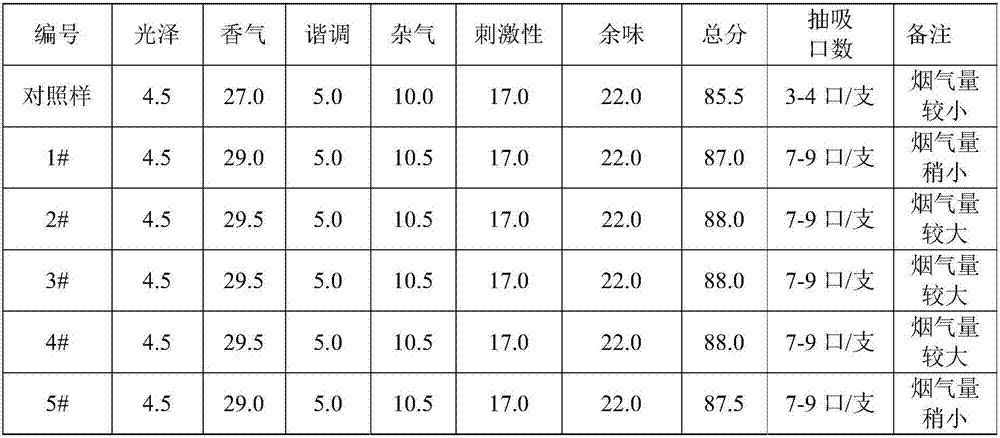

[0048] Quantitative 95.0±3.0g / m 2 , The dry-process reconstituted tobacco leaves with a thickness of 0.25±0.02mm are cut into multiple long shredded tobacco in one direction by a cutting device, and the width of the long shredded tobacco is 0.5mm, and the multi-slender shredded tobacco is cut by a cigarette rolling machine or a filter rod forming machine, etc. The device laterally squeezes the shredded tobacco and closes it into an orderly arranged shredded tobacco rod, and then wraps the forming paper to form a cylindrical tobacco rod in which the shredded tobacco is arranged in an orderly manner. The strip is cut according to the length of 12.0 mm and then connected with the cigarette filter tip to form a heat-not-burn cigarette 1#.

[0049] Set the width of the long shredded tobacco to 0.8mm, 1.0mm, 1.2mm, and 1.5mm respectively, and repeat the above-mentioned process to obtain 4 heat-not-burn cigarettes 2#, 3#, and 4# with different widths of the shredded tobacco , 5# sam...

Embodiment 3

[0054] Quantitative 95.0±5.0g / m 2 Thick pulp reconstituted tobacco leaves with a thickness of 0.20±0.02mm are cut into multiple strips of shredded tobacco in one direction with a cutting device, and the width of the strips of shredded tobacco is 0.5mm. and other devices along the lateral extrusion of the shredded tobacco to form an orderly arranged shredded tobacco rod, and then wrap the forming paper to form a cylindrical tobacco rod with an orderly arrangement of the shredded tobacco. After the tobacco rod is cut according to the length of 15.0 mm, it is connected with the cigarette filter tip to form a 1# heat-not-burn cigarette.

[0055] Set the widths of the long shredded tobacco to 0.8mm, 1.0mm, 1.2mm, and 1.5mm respectively, repeat the above-mentioned process, and obtain 4 heat-not-burn cigarettes 2#, 3#, 4#, 5# sample. In addition, using the conventional cigarette technology, the reconstituted tobacco leaves of the thick pulp method are cut into small pieces (general...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com