Method for eliminating pinhole-shaped pock flaws of pickling plate

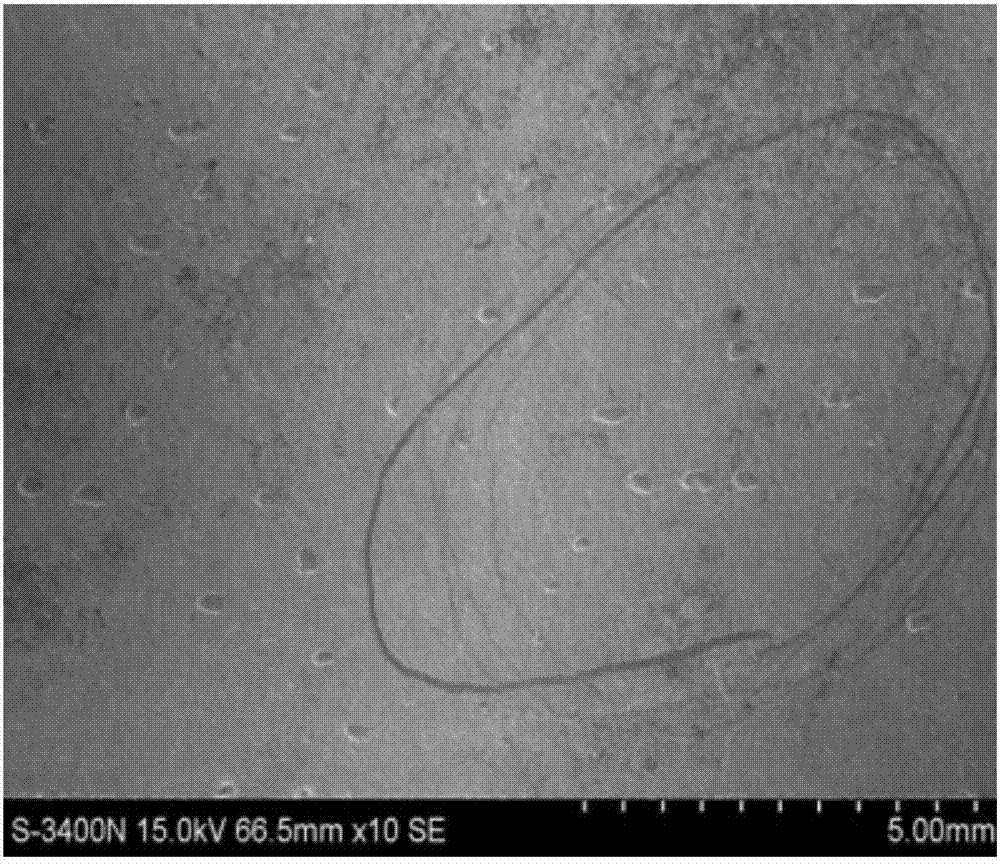

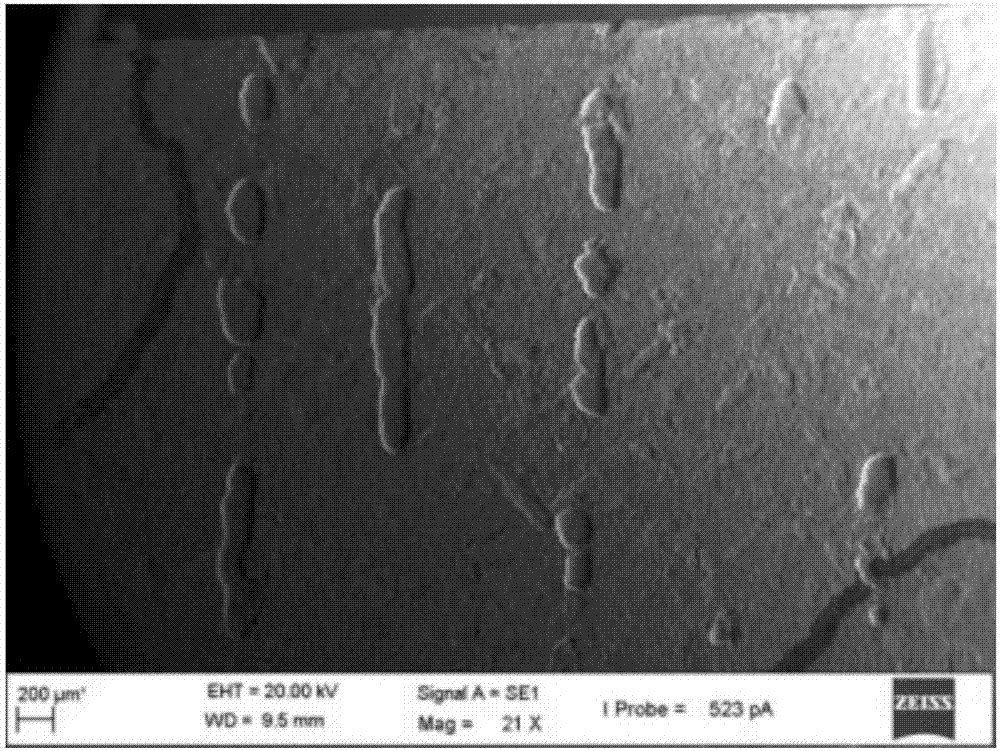

A pickling plate and pitting technology, which is applied in the field of steel rolling, can solve the problem of pinhole-shaped pitting and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

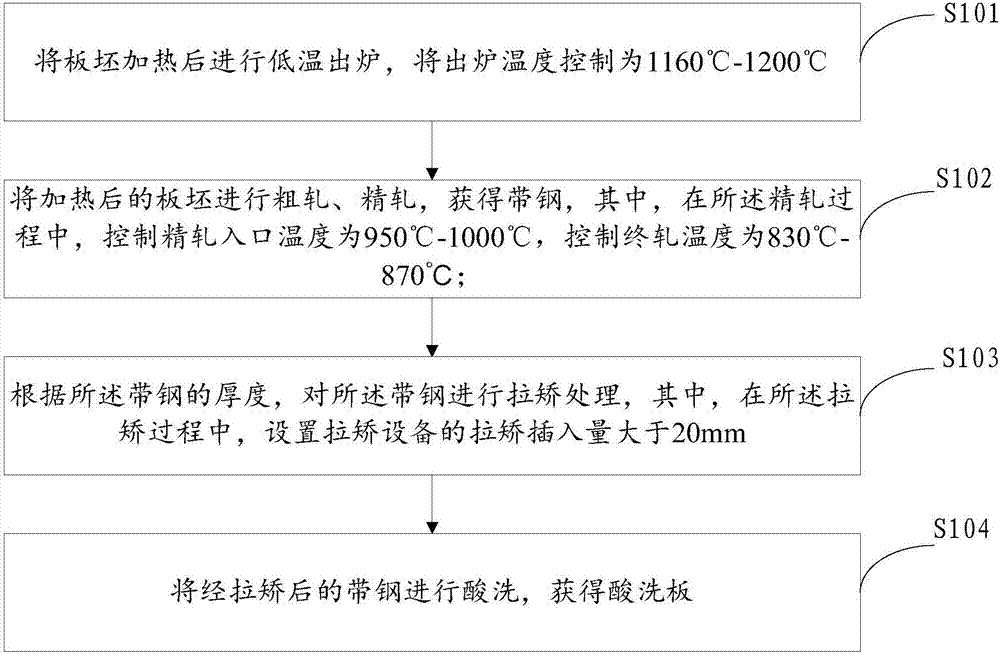

[0032] The embodiments of the present invention provide a method for eliminating pinhole-like pitting defects of pickling plates, which solves the technical problem that pinhole-like pitting easily occurs on the surface of hot-rolled pickling plates in the prior art. The technical effect of simply and effectively eliminating pinhole-like pits on the surface of the pickling board is realized.

[0033] In order to solve the technical problems in the above-mentioned prior art, the general idea of the technical solution provided by the embodiment of the present application is as follows:

[0034] After the slab is heated, it is released from the furnace at a low temperature, and the temperature of the furnace is controlled at 1160°C-1200°C;

[0035] performing rough rolling and finish rolling on the heated slab to obtain strip steel, wherein, in the finish rolling process, controlling the finish rolling inlet temperature to be 950°C-1000°C, and controlling the finish rolling tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com