Device for processing apparatus, particularly for laser processing apparatus, and laser processing apparatus

A technology of laser processing and processing equipment, which is applied to the device in the preamble and the field of laser processing equipment, and can solve the problems of inability to suck away particles or emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

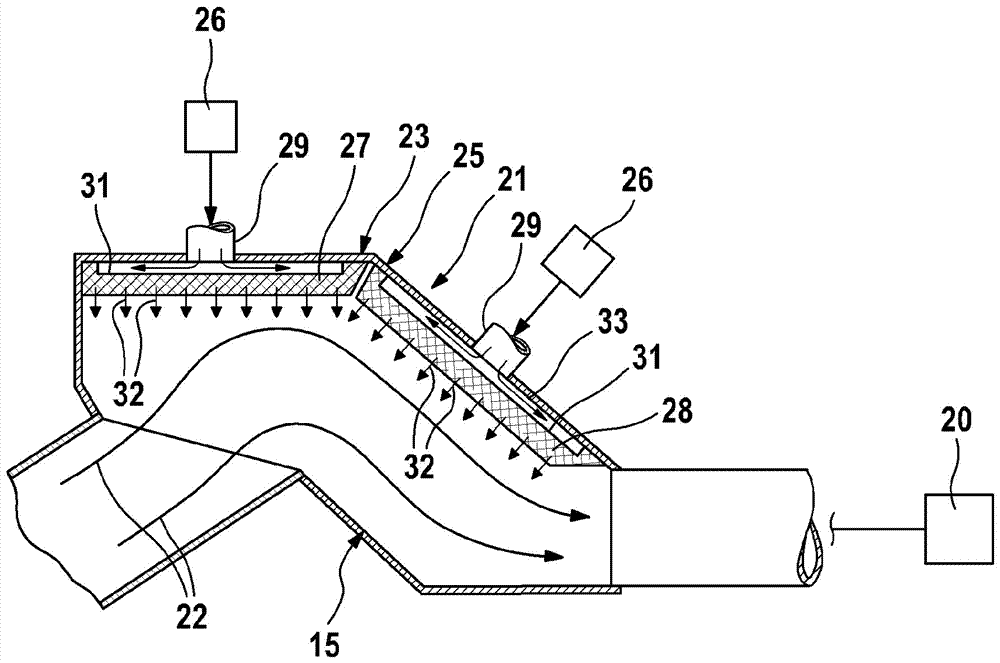

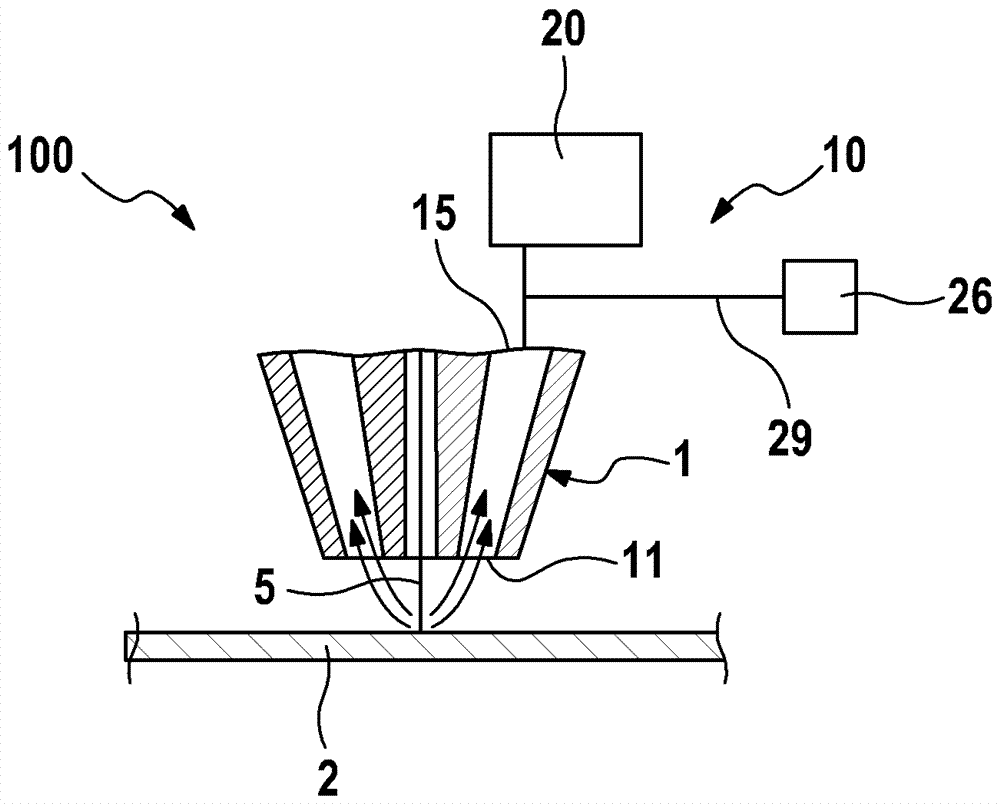

[0020] exist figure 1 A treatment head 1 of a treatment device designed as a laser treatment device 100 is shown in a strongly simplified manner in FIG. The laser processing device 100 is used, for example, for the separation or shearing of a workpiece 2 which is formed, for example, in the form of a sheet. For this purpose, a laser beam 5 emerges from the treatment head 1 of the laser treatment system 100 , which is guided by an optical system (not shown) and which strikes, for example, perpendicularly to the surface of the workpiece 2 . When the laser beam 5 hits the workpiece surface, the material of the workpiece 2 is melted or evaporated. The vaporized material of the workpiece 2 is a particle-containing emission. In order that these emissions or particles do not settle on the workpiece surface 2 , the laser processing device 100 also has a device 10 for suctioning the emissions or particles from the region of the workpiece 2 .

[0021] The device 10 has, for example, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com