Circular disc positioning assembly

A technology for positioning components and discs, used in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low degree of automation, increase production costs, long labor time, etc., achieve high degree of automation, improve quality, and solve positioning problems troublesome effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

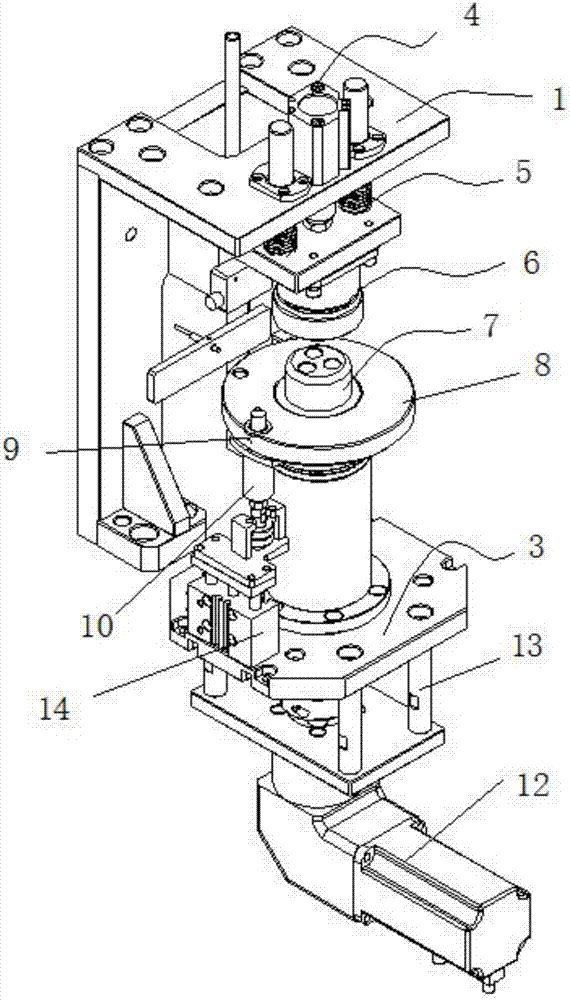

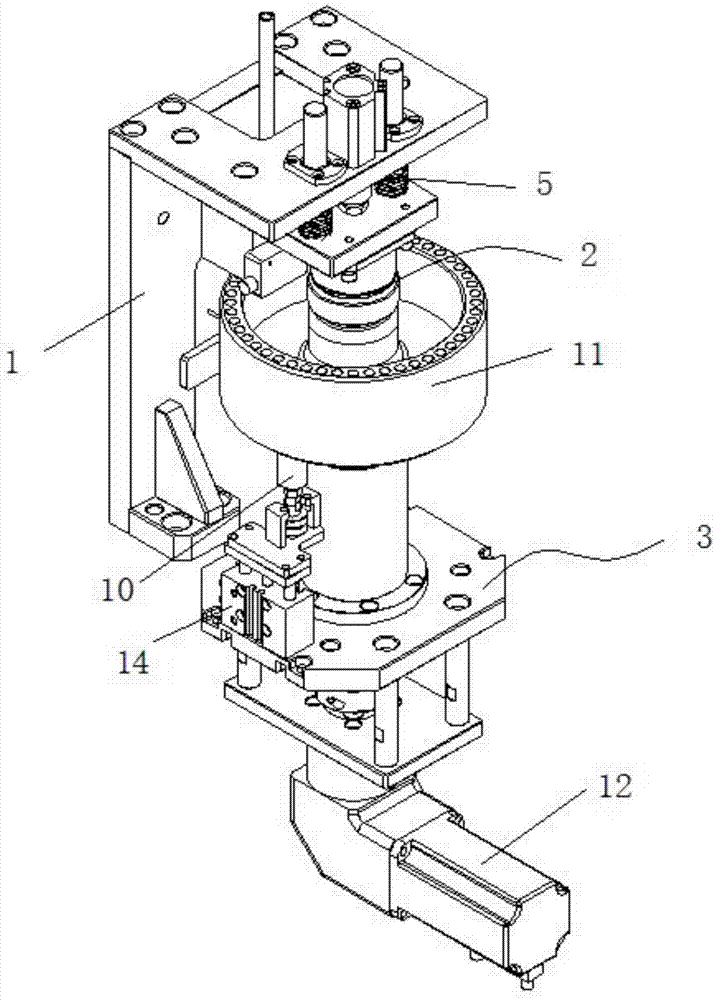

[0013] See figure 1 and figure 2 A disc positioning assembly shown has a fixed bracket 1, a pressing mechanism 2, and a jacking mechanism 3. The pressing mechanism 2 is fixed on the fixing bracket 1, and the jacking mechanism 3 is arranged on the At the bottom, the pressing mechanism 2 includes a cylinder 4, a spring assembly 5, and a central shaft 6. The positioning plate 8 has a pin hole 9, and the pin 10 of the jacking part 3 is mated with the pin hole 9. The positioning shaft 7 is socketed with the positioning disc 8, and the two are rotated clockwise through a one-way bearing. The fixing bracket 1 is provided with a sensor, and the sensor is arranged above the positioning plate 8 for sensing the position of the pin hole 9 . Jacking part 3 comprises servomotor 12, is positioned at described servomotor 12 top and is provided with support 13, and one end of described support 13 has ejector 14, and described ejector 14 is provided with pin 10.

[0014] Its working process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com