Drilling perpendicularity monitoring system

A monitoring system and verticality technology, which is applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problem of inability to accurately determine the direction of inclination, cannot realize verticality monitoring, and cannot be applied to various curved surfaces to be processed, etc. problem, to achieve the effect of saving resources and strong portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

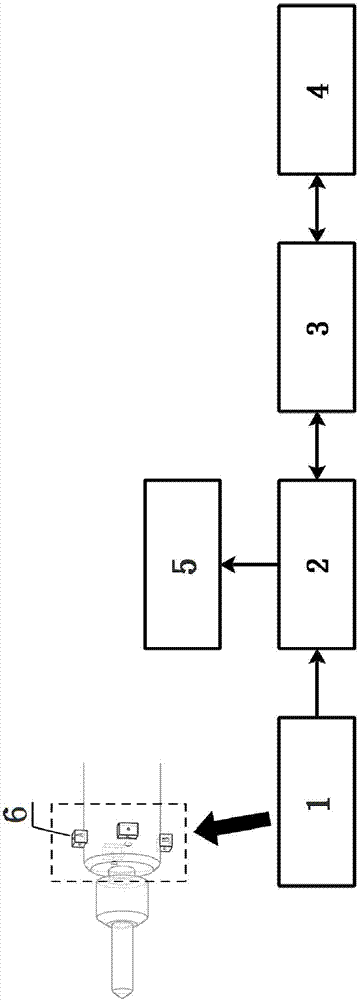

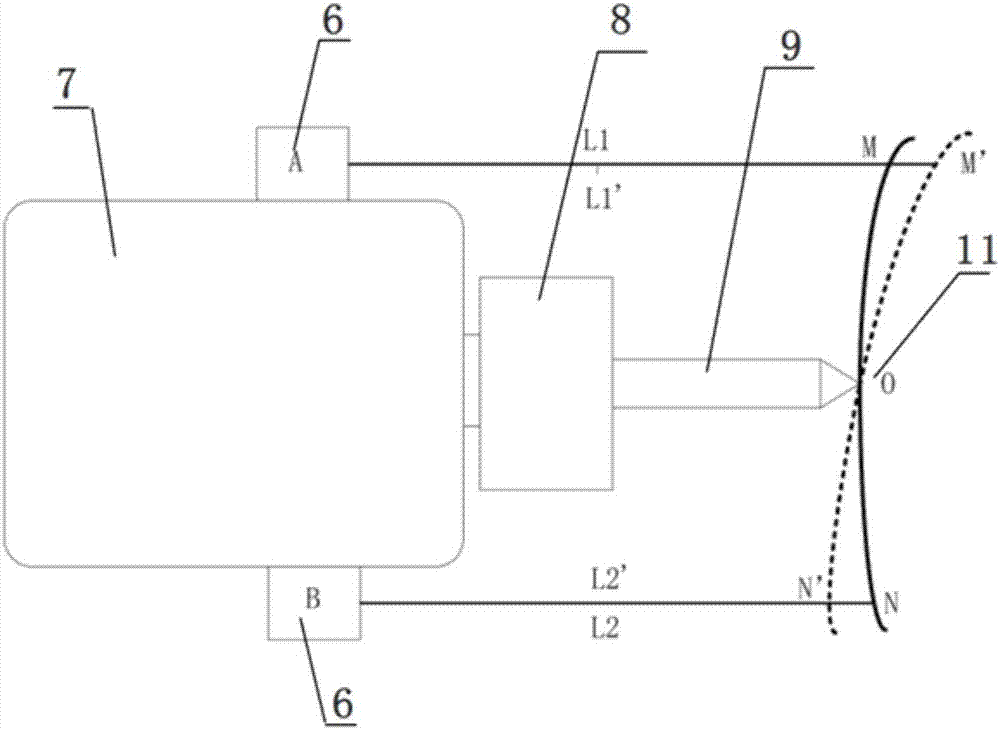

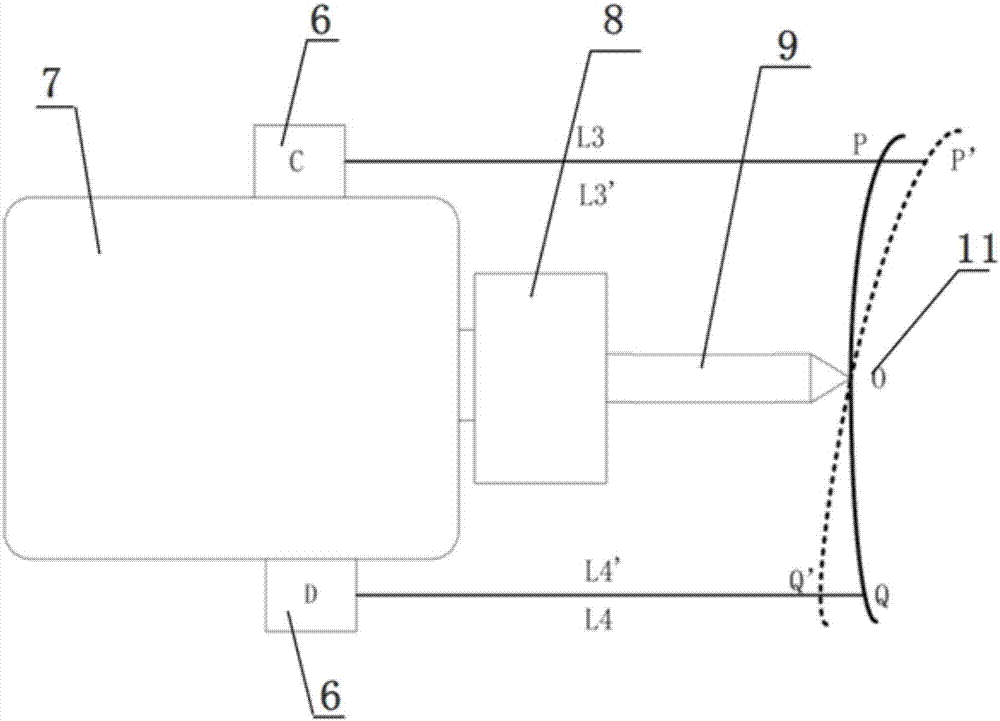

[0039] A drilling verticality monitoring system includes a sensing module 1 , a control module 2 , a communication module 3 , a host computer 4 and a display module 5 . The sensing module 1 is composed of symmetrically distributed laser ranging modules 6 . Use the laser distance measuring module 6 to measure the distance to the surface to be processed, calculate the verticality of the drill gun through the control module 2, send it to the display module 5 for displaying the verticality, and transmit the data to the host through the communication module 3 Machine 4 meets the needs of digital measurement and control of equipment.

[0040] The device is mainly aimed at real-time monitoring of the verticality of boreholes on irregular curved surfaces and cylindrical curved surfaces, and can also take into account the vertical drilling of plane and regular curved surfaces.

[0041] The sensing module 1 needs to adopt four ranging modules 6, A, B, C, and D at the same time, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com