A color mixing 3D printer nozzle and printing method

A technology of 3D printers and nozzles, applied in 3D object support structures, metal processing equipment, manufacturing tools, etc., can solve the problems of uneven color mixing of materials, easy blockage of color mixing nozzles, etc., and achieve the effect of sufficient materials, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

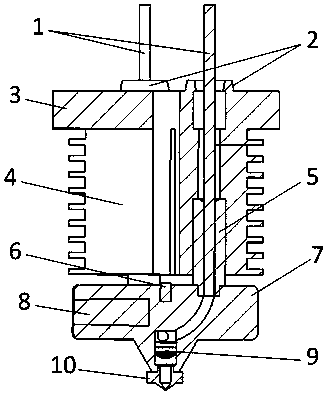

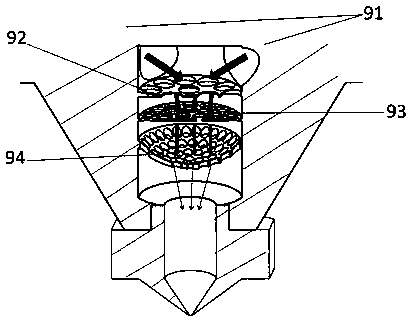

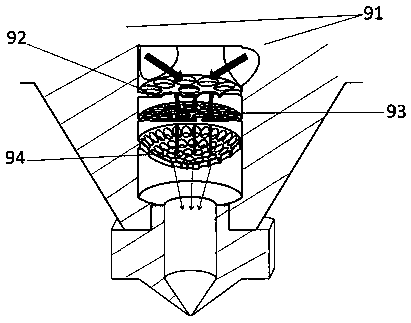

[0015] refer to figure 1 and figure 2 , the color mixing nozzle of the fused deposition type color 3D printer of the present invention includes the three primary color filaments 1, the three primary color filaments 1 are inserted into the feed port 2, the fixing device 3 is fixed on the printer frame, and there are screw holes around the fixing device 3 for installation Cooling fan, the lower part is connected to the cooling device 4, each cooling device is wrapped with a throat 5, the throat is connected to the heating block 7, a temperature sensor 6 is installed in the middle of the heating block, used to detect and control temperature changes, the cooling device It is a fan-shaped heat dissipation mechanism with ups and downs, which is assembled outside the throat to absorb and dissipate its heat. It is an improved heat dissipation device for specific applications of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com