Preparation method of high-purity lithium silicate solution

A lithium silicate, high-purity technology, applied in silicates, alkali metal silicates, chemical instruments and methods, etc., can solve the problems of low modulus, high cost, low concentration of active silicic acid, etc., and achieve a preparation method. Simple, high performance and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

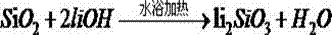

[0017] A preparation method of high-purity lithium silicate solution, comprising the following steps:

[0018] (1) Refining of acidic silica sol: Soak the acidic silica sol with an acid of PH: 2-5 for 0.5-2h, then pass the acidic silica sol through a strongly acidic cation exchange column at a flow rate of 10-30L / min; finally obtain the concentration It is 5-8% acidic silica sol; used to neutralize Na in acidic silica sol + .

[0019] (2) Under stirring, dissolve the lithium source compound in deionized water, the concentration range of preparation is: 1-10wt% solution, and the stirring time is 0.5-12h;

[0020] (3) In a water bath at 40-80°C, slowly add the solution in (1) to the solution prepared in (2) according to the li:Si molar ratio of 2-2.1:1, and stir continuously for 0.5-5h to form dilute silicon lithium acid solution;

[0021] (4) Refining of dilute lithium silicate solution: Dilute lithium silicate aqueous solution passes through a strong acid cation exchange co...

Embodiment 1

[0030] (1) Refining the acidic silica sol, first soak the acidic silica sol in hydrochloric acid with a pH of 4 for 1 hour, and then pass the acidic silica sol through the exchange column of strong acidic styrene-based cation exchange resin at a flow rate of 12L / min , to obtain a concentration of 6wt%, SiO 2 The mass percentage is the refining acidic silica sol of 30%, takes by weighing 243g refining acidic silica sol;

[0031] (2) According to the molar ratio li:Si=2:1, weigh 5gliOH powder and dissolve it in 95g deionized water, stir for 3h to obtain: 100g, 5wt% liOH aqueous solution;

[0032] (3) Slowly add the refined acidic silica sol into the prepared liOH aqueous solution, and stir for 2 hours in a water bath at 50°C to make a dilute lithium silicate solution;

[0033] (4) Pass the dilute lithium silicate solution through the exchange column of strongly acidic styrene-based cation exchange resin at a flow rate of 15L / min to neutralize excess li + ;

[0034] (5) Finall...

Embodiment 2

[0036] (1) Refining the acidic silica sol, first soak the acidic silica sol in acetic acid with a pH of 5 for 1.5 hours, and then pass the acidic silica sol through the exchange column of strong acidic styrene-based cation exchange resin at a flow rate of 15L / min, get concentration 5wt%, SiO 2 The mass percentage is the refining acidic silica sol of 35%, takes by weighing 371.4g refining acidic silica sol;

[0037] (2) According to the molar ratio li:Si=2:1, weigh 8gliOH powder and dissolve it in 92g deionized water, and stir for 6h to obtain: 100g, 8wt% liOH aqueous solution;

[0038] (3) Slowly add the refined acidic silica sol into the prepared liOH aqueous solution, and stir for 4 hours in a water bath at 60°C to make a dilute lithium silicate solution;

[0039] (4) Pass the dilute lithium silicate solution through the exchange column of strongly acidic styrene-based cation exchange resin at a flow rate of 18L / min to neutralize excess li + ;

[0040] (5) Finally, the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com