A kind of on-line rapid spheroidizing annealing method of gcr15 bearing steel after hot rolling

A spheroidizing annealing and bearing steel technology, applied in the field of bearing steel heat treatment, can solve the problems of long spheroidizing time and shortening spheroidizing annealing time, and achieve the effects of short isothermal time, low rolling resistance and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

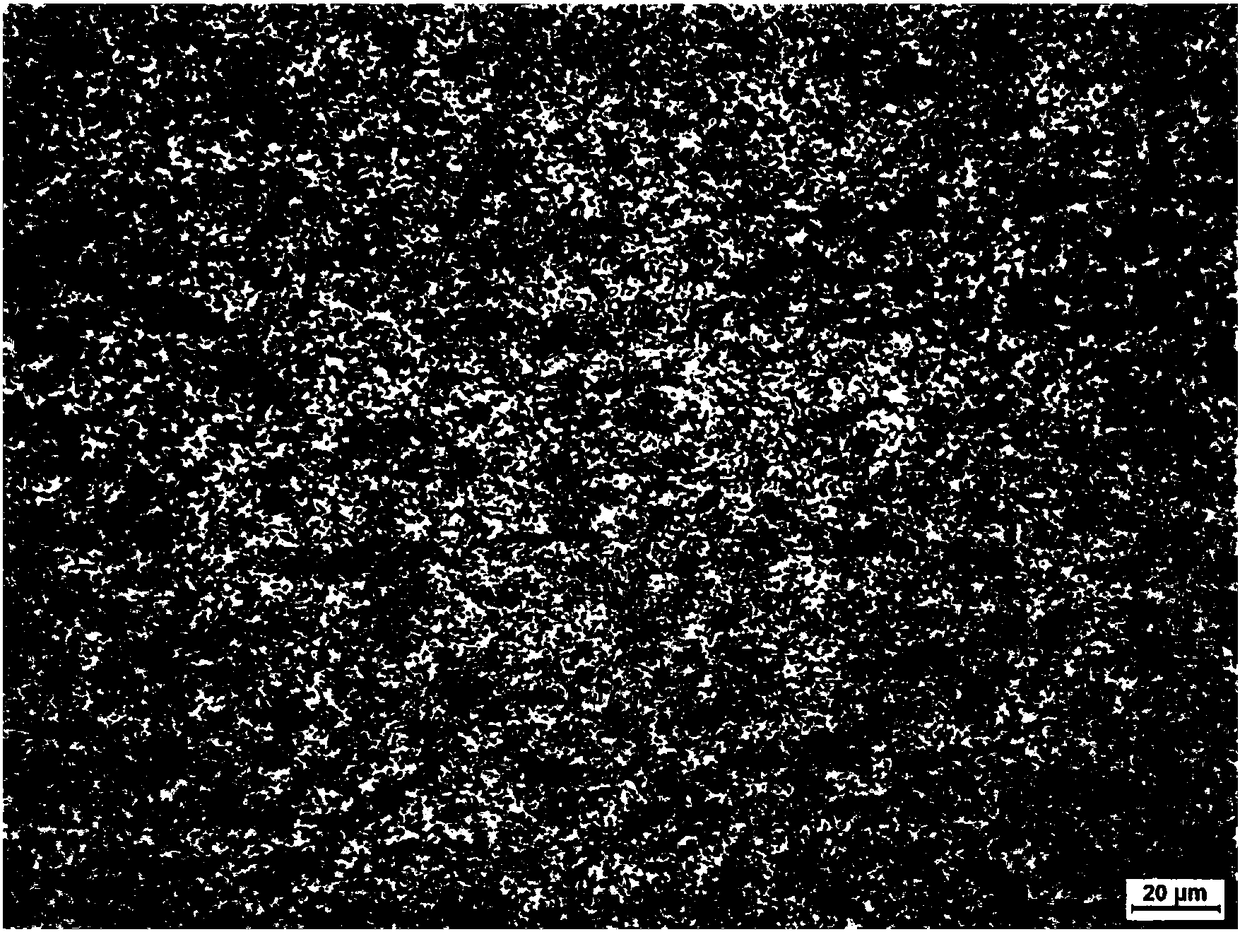

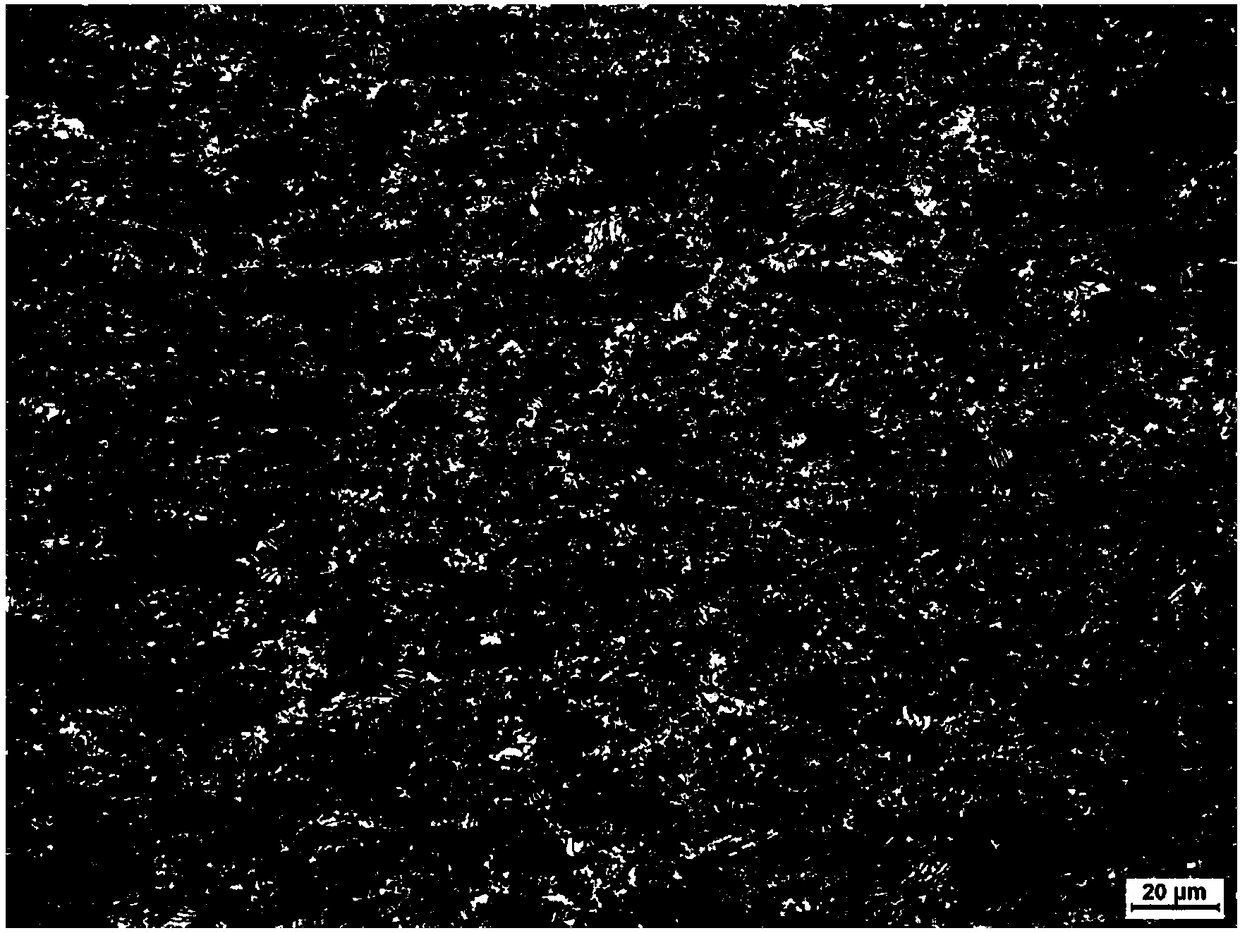

Examples

Embodiment 1

[0035] The online rapid spheroidizing annealing method of the GCr15 bearing steel in this embodiment is carried out according to the following steps:

[0036] 1. Heat the sample to be rolled to 1000°C in a high-temperature box-type resistance furnace, and treat it isothermally for 30 minutes.

[0037] 2. The initial thickness of the sample is 25mm. After isothermal treatment, a single-pass rolling is carried out at 1000°C to refine the austenite grains. The reduction is 7mm, and the thickness after rolling is about 18mm.

[0038] 3. After the first pass of rolling, air-cool and wait until the temperature reaches 780°C, and carry out three consecutive passes of rolling. About 760°C.

[0039] 4. Put the rolled steel plate into the east and west through-type heat treatment furnaces for isothermal treatment. The isothermal temperature is 720°C, and the isothermal time is 4h. After the isothermal treatment, the furnace is cooled to 600°C, and the furnace-cooled plate is air-cooled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com