Low-carbon silicon-manganese bainite high-strength steel and production method thereof

A carbon-silicon-manganese system and production method technology, applied in the field of low-carbon silicon-manganese bainitic high-strength steel and its production, can solve the problems of complex production process, low production efficiency and high production cost, and achieve short isothermal time and low cost. Low, the effect of improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

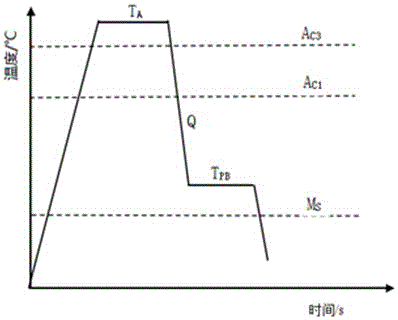

[0019] Embodiment 1: The production method of the low-carbon silicomanganese-based bainitic high-strength steel adopts the following process steps.

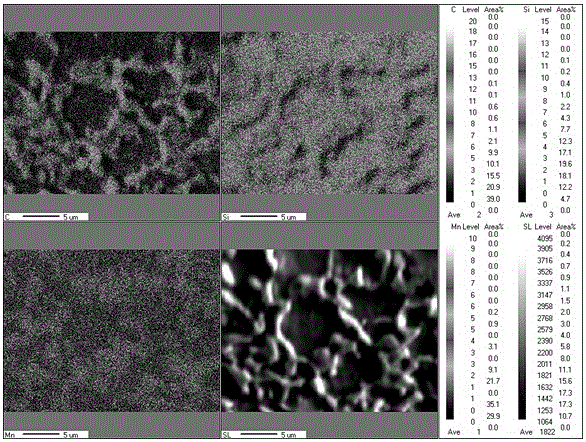

[0020] (1) After the molten steel is smelted and cast into billets, it is forged into slabs; the mass percentages of chemical components in the slabs are: C0.15%, Si1.8%, Mn1.5%, P0.04%, S0 .02%, the balance is Fe and unavoidable impurities.

[0021] (2) Hot rolling and cold rolling process: the slab is hot rolled and cold rolled to obtain the final rolled plate; the hot rolling process is followed by rough rolling and finish rolling; the starting temperature of rough rolling is 1030°C, and the rough rolling pass The deformation is 25%; the total deformation of the finish rolling is 55%, the final rolling temperature is 830°C, and the thickness of the hot rolling final rolling is 5mm; then it is cold-rolled to 2mm through the cold rolling process.

[0022] (3) Heat treatment process: the final rolling plate is heated to 780°C at...

Embodiment 2

[0024] Embodiment 2: The production method of the low-carbon silicomanganese-based bainitic high-strength steel adopts the following process steps.

[0025] (1) After molten steel is smelted and cast into blanks, it is forged into slabs; the mass percentages of chemical components in the slabs are: C0.17%, Si1.56%, Mn1.8%, P0.05%, S0 .03%, the balance is Fe and unavoidable impurities.

[0026] (2) Hot-rolling and cold-rolling process: hot-rolling and cold-rolling the slab to obtain the final-rolled plate; hot-rolling is followed by rough-rolling and finish-rolling; The amount is 35%, the total deformation of the finish rolling is 50%, the finish rolling temperature is 850°C, and the thickness of the hot rolling finish rolling is 5mm; then it is cold rolled to 2mm through the cold rolling process.

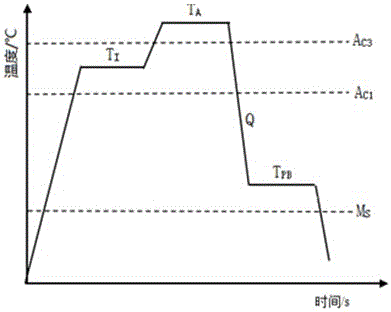

[0027] (3) Heat treatment process: the final rolling plate is heated up to 800°C at 10°C / s, and held for 1800s; then heated to 950°C at 12°C / s, held for 600s; quenched in a salt ba...

Embodiment 3

[0029] Embodiment 3: The production method of the low-carbon silicomanganese-based bainitic high-strength steel adopts the following process steps.

[0030] (1) After molten steel is smelted and cast into blanks, it is forged into slabs; the mass percentages of chemical components in the slabs are: C0.22%, Si1.2%, Mn1.6%, P0.04%, S0 .02%, the balance is Fe and unavoidable impurities.

[0031] (2) Hot-rolling and cold-rolling process: hot-rolling and cold-rolling the slab to obtain the final-rolled plate; hot-rolling is followed by rough-rolling and finish-rolling; The amount is 30%, the total deformation of the finish rolling is 60%, the finish rolling temperature is 840°C, and the thickness of the hot rolling finish rolling is 6mm; then it is cold rolled to 3mm through the cold rolling process.

[0032] (3) Heat treatment process: the final rolling plate is heated up to 800°C at 8°C / s and held for 1200s; then heated to 980°C at 10°C / s and held for 600s; quenched in a salt ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com