Replacement equipment of railroad sleeper

A technology for replacing equipment and sleepers, which is applied to roads, tracks, laying tracks, etc., can solve the problems of low automation, low work efficiency, and high labor costs, and achieve the effects of high operating efficiency, easy operation, and high automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

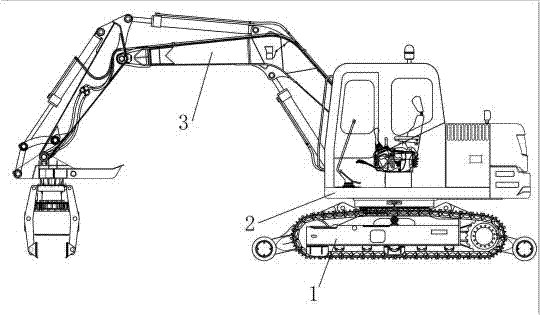

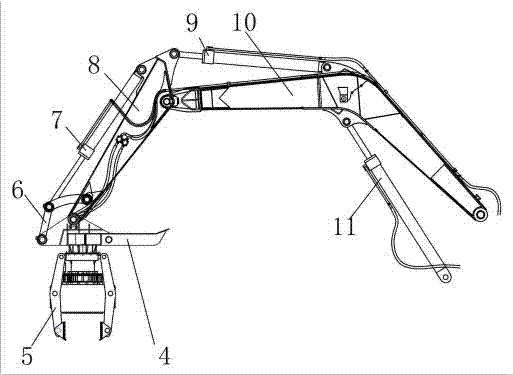

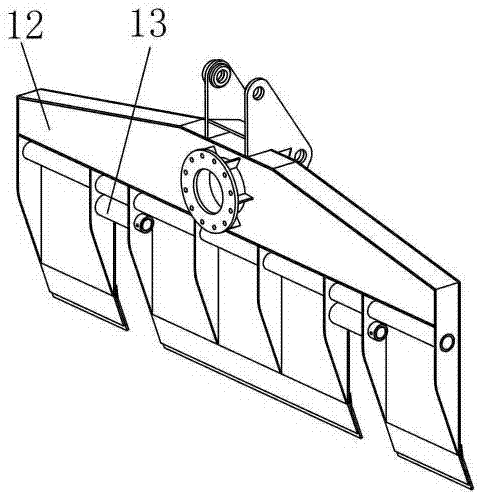

[0029] like Figure 1 to Figure 10 Shown: a kind of railway sleeper replacement equipment, it is characterized in that, comprises getting off the car assembly 1, getting on the car assembly 2, working device 3 and guiding mechanism 24, wherein:

[0030] Described getting off assembly 1 comprises getting off frame 23, walking assembly 22, and running assembly 22 is installed on the bottom both sides of getting off frame 23, is used for realizing the walking function of equipment whole;

[0031] The boarding assembly 2 is installed on the upper part of the disembarking assembly 1, and the boarding assembly 1 is also provided with a travel control device 29, which is arranged in the driver's compartment, and is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com