Signal conversion shaft and superfill monitoring device for cast-in-situ piles using the signal conversion shaft

A signal conversion and monitoring device technology, which is applied in the test of basic structure, construction, basic structure engineering, etc., can solve the problems of waste of concrete for subsequent construction, the inability to guarantee the bottom of heavy objects or bamboo poles, and the increase in the production cost of the shaft body. The effect of control accuracy and perfusion efficiency, high usability and promotion value, and saving equipment maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

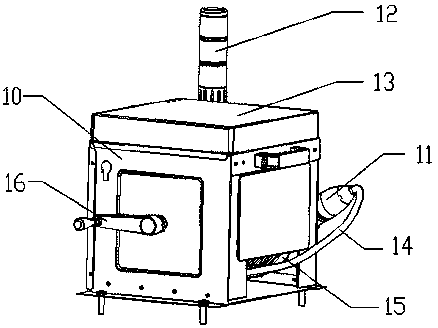

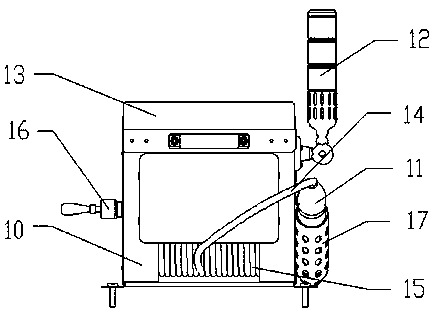

[0029] The invention discloses a signal conversion shaft and a monitoring device for overfilling of cast-in-situ piles used in the process of pouring concrete by using the signal conversion shaft.

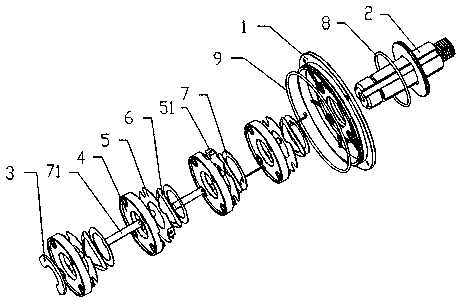

[0030] Such as figure 1 As shown, a signal conversion shaft includes a left end cover (not shown in the figure) and a right end cover 1, which is characterized in that it also includes a fixed shaft 2 that passes through the right end cover 1 and is fixedly connected with the right end cover 1, And a rotating mechanism arranged between the left end cover and the right end cover 1 and rotatably sleeved on the fixed shaft 2, the rotating mechanism is electrically connected to the fixed shaft 2, and the rotating mechanism is connected to the fixed shaft 2 An E-shaped retaining ring 3 is also arranged between the left end caps to realize tight fitting inside the rotating mechanism.

[0031] The rotating mechanism includes at least two sets of matching rotating assemblies, and each gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com