Structure and construction method for frame-shear wall structure application fabricated structure self-insulating strip

A frame-shear structure and assembled technology, which is applied in thermal insulation, building structure, formwork/formwork/working frame, etc., can solve the problems of difficult construction, affecting construction progress, and long construction period, so as to avoid oxidation damage , The effect of reducing the risk of shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

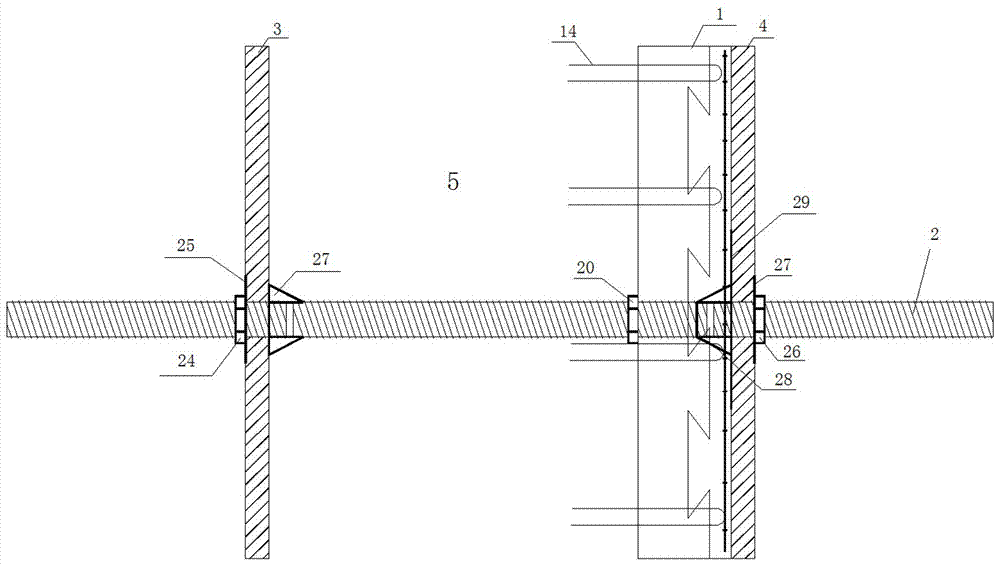

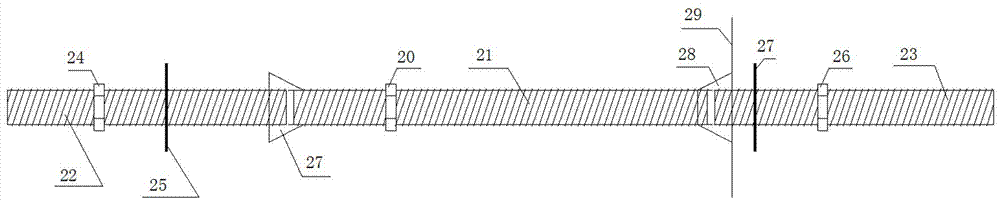

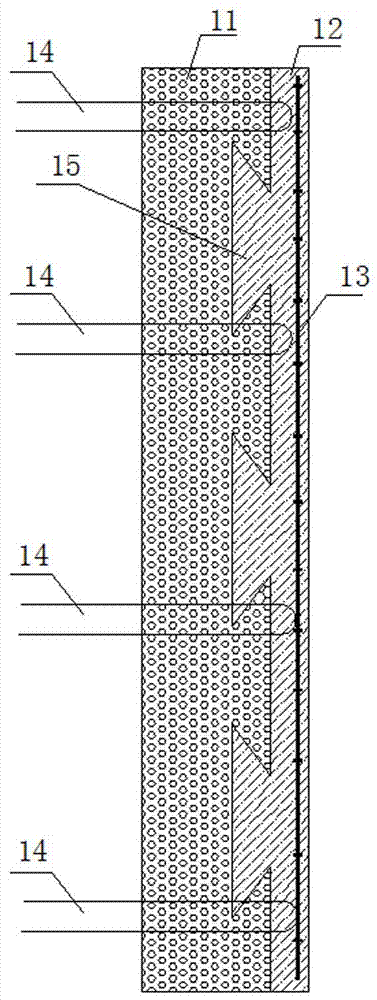

[0035] Example: such as Figure 1-3 As shown in the figure, a frame-shear structure exterior wall is constructed with prefabricated structure self-insulation slats, including inner formwork 3, outer formwork 4, prefabricated structure self-insulation slats 1 and built-in wall-through anchors 2, and built-in through-wall anchors Bolt 2 is made up of two fixed formwork screws 22,23 and an intermediate support screw 21, and the two ends of the intermediate support screw 21 are respectively connected with the fixed formwork screws 22,23 on both sides by inner and outer conical nuts 27,28. , The small ends of the outer conical nuts 27, 28 are towards the center.

[0036] The fixed formwork screw rod 22 on the inner side is screwed with an inner baffle 25 and an inner nut 24, and the inner template 3 is threaded on the fixed formwork screw 22 between the inner baffle 25 and the inner tapered nut 27 and is tightened and fixed;

[0037] The fixed formwork screw 23 on the outside is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com