Compressor and heat pump system

A technology of heat pump system and compressor, which is applied in the direction of pump control, pump components, mechanical equipment, etc., can solve the problems of compressor wear and burnout, improve working stability, avoid abnormal wear or compressor burnout, and avoid abnormal Effects of worn or compressor burnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

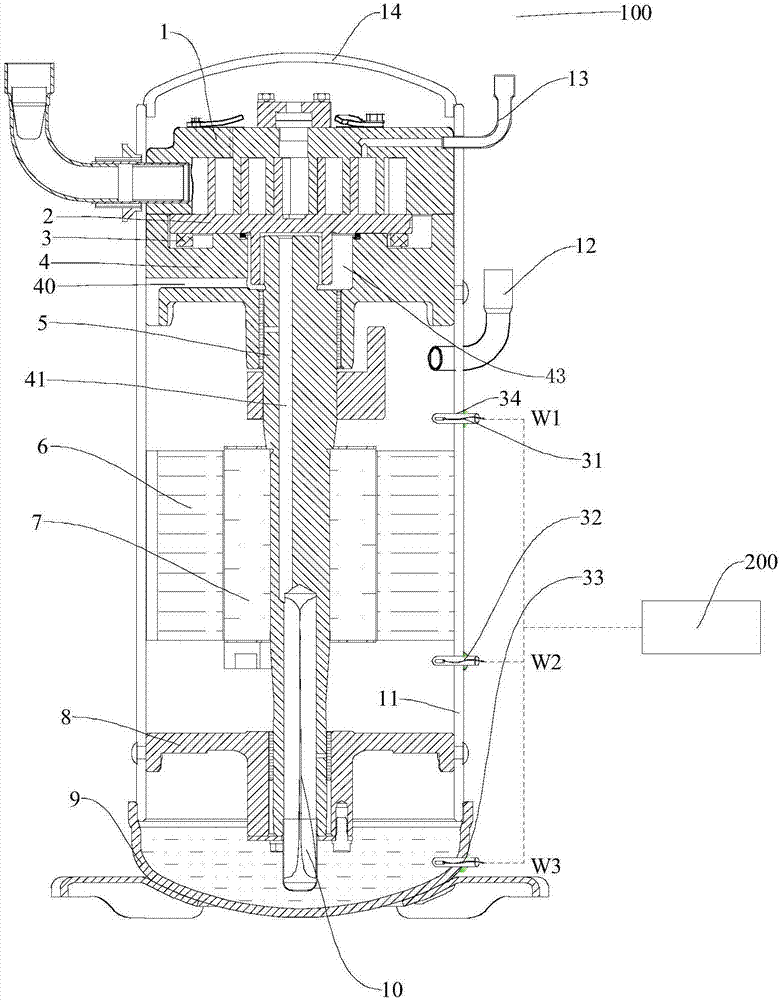

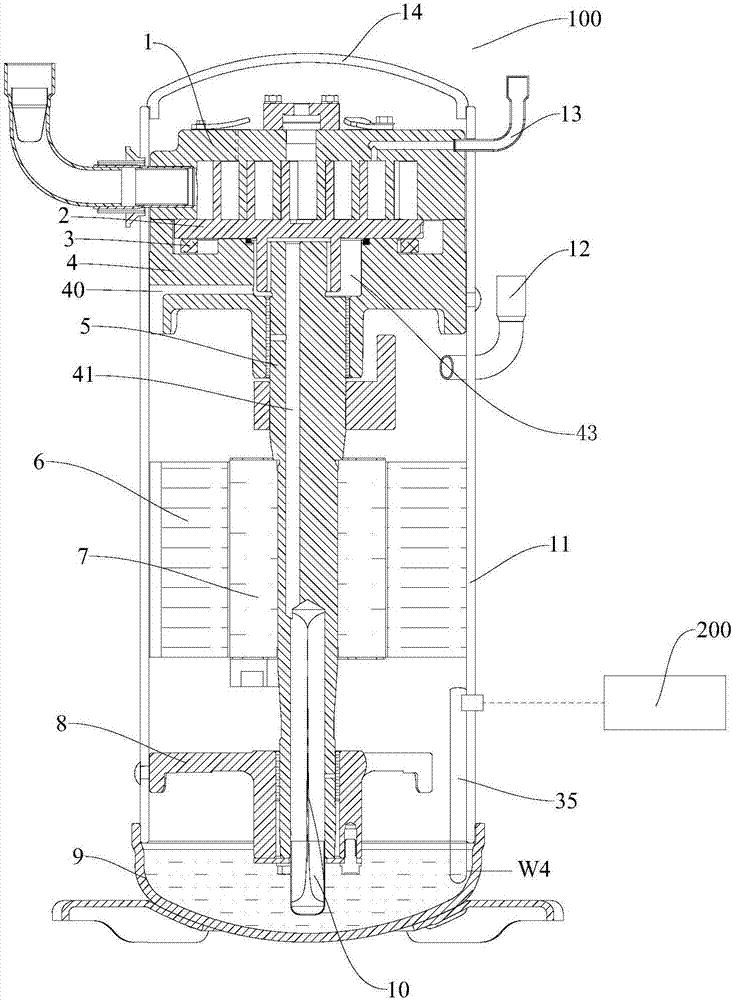

[0072] Such as image 3 As shown, the main structure of the compressor in this embodiment is the same as that in Embodiment 1. The lower space of the stator 6 is attached to the inner surface of the housing 11, and a liquid level sensor 35 can be installed axially, which is connected to the Data acquisition center, and pre-calibrate the minimum oil level position W4, the liquid level sensor 35 can directly measure the oil level height, if the oil level is above the minimum oil level, no oil return control is required; if the oil level reaches the minimum oil level or below, turn on the oil return control to ensure that the compressor always has enough lubricating oil. The liquid level sensor 35 can be fixed on the inner wall of the housing 11 by means of spot welding, etc., and the data line passing through the housing 11 is fixed with the housing by means of glass surrounding the data line, etc., and realizes the sealing at this place.

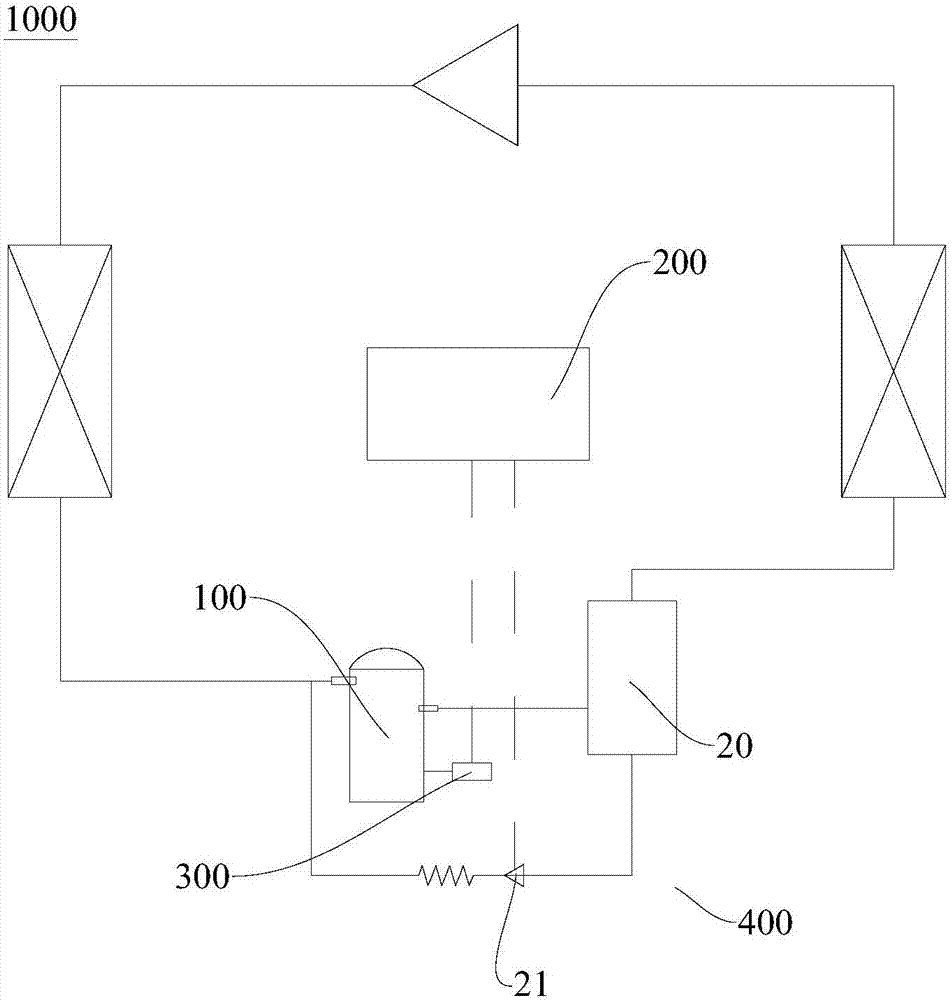

[0073] The heat pump system 1000 acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com