Rolling shaft supporting bearing of hot air rotary furnace

A technology for supporting bearings and rotary furnaces, applied in the directions of shafts and bearings, bearing components, and rigid supports for bearing components, etc., which can solve problems such as easy deformation, increased clearance between rollers and bearing housings, and impact on the reliability of rollers. , to achieve the effect of preventing gap changes and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

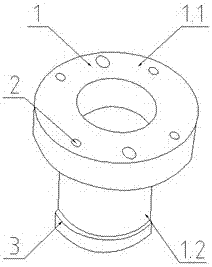

[0017] Such as figure 1 As shown, a hot blast rotary furnace roller support bearing in this embodiment includes a bearing body 1, and the bearing body 1 includes a round pipe section 1.1, and a shaft hole 1.3 is opened in the center of the round pipe section 1.1. A circular boss 1.2 is provided at the upper end of the circular pipe section 1.1, and a plurality of cooling holes 2 are opened on the circular boss 1.2 along its radial direction, and a reinforcement ring 3 is provided at the lower end of the circular pipe section 1.1.

[0018] In addition to the above-mentioned embodiments, the present invention also includes other implementations, and any technical solution formed by equivalent transformation or equivalent replacement shall fall within the protection scope of the claims of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com