Biochemical treatment method of refinery wastewater

A technology for oil refinery wastewater and biochemical treatment, applied in natural water treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as harsh start-up conditions and poor universality of granular sludge, and save infrastructure Investment and operating costs, improving the effective utilization rate, and enhancing the effect of degradation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

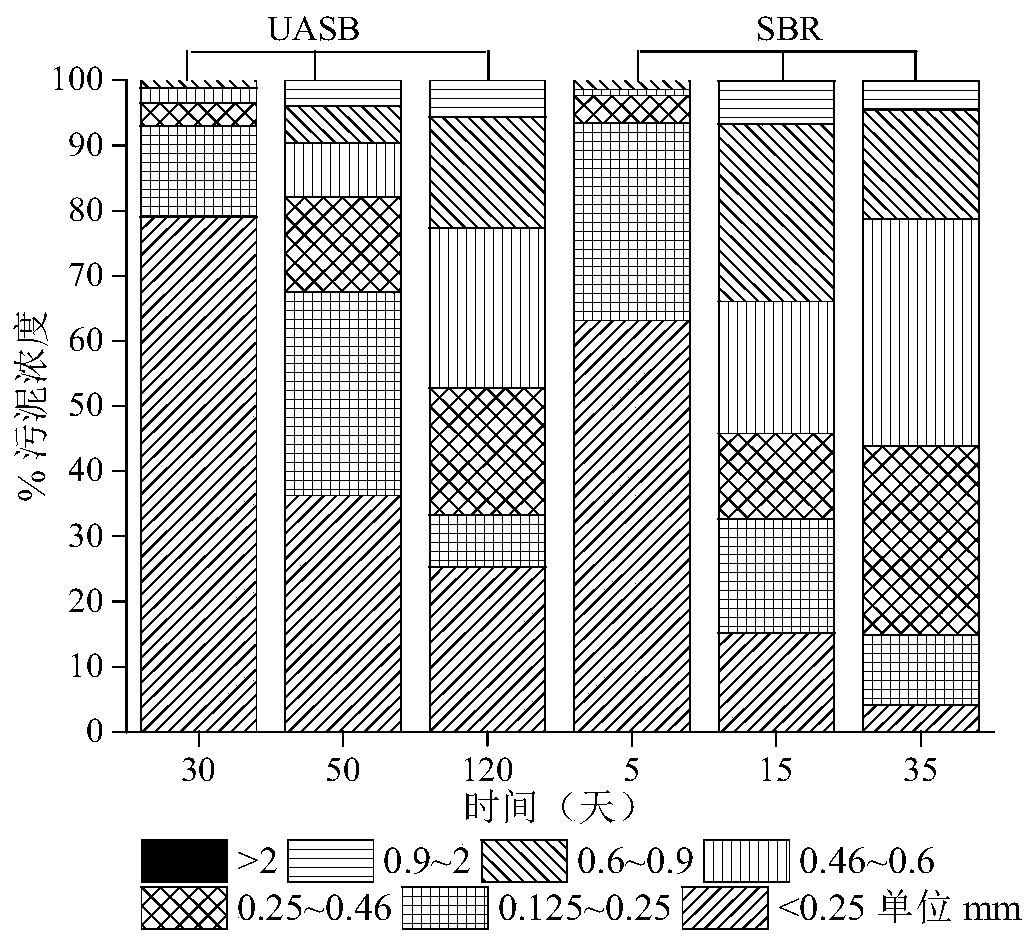

Embodiment 1

[0111] The treatment object of this embodiment is the oily waste water of a certain refinery. After the oily waste water is diluted and deoiled pre-treated, the oil content is 150-170 mg / L, the COD is 800-1000 mg / L, and the ammonia nitrogen is 8-25 mg / L. L of refinery wastewater to be treated. According to the volume of UASB and SBR, the amount of treated water in this implementation is 0.2m 3 / d.

[0112] The first influent is the diluted product of refinery wastewater to be treated, which is used for the cultivation and domestication of anaerobic granular sludge. The oil content of the first influent is 120mg / L, and the COD is 500-600mg / L;

[0113] The second influent is the diluted product of refinery wastewater to be treated, which is used for the cultivation and domestication of aerobic granular sludge. The oil content of the second influent is 70mg / L, and the COD is 200-300mg / L;

[0114] The present embodiment comprises the following steps to the biochemical treatment ...

Embodiment 2

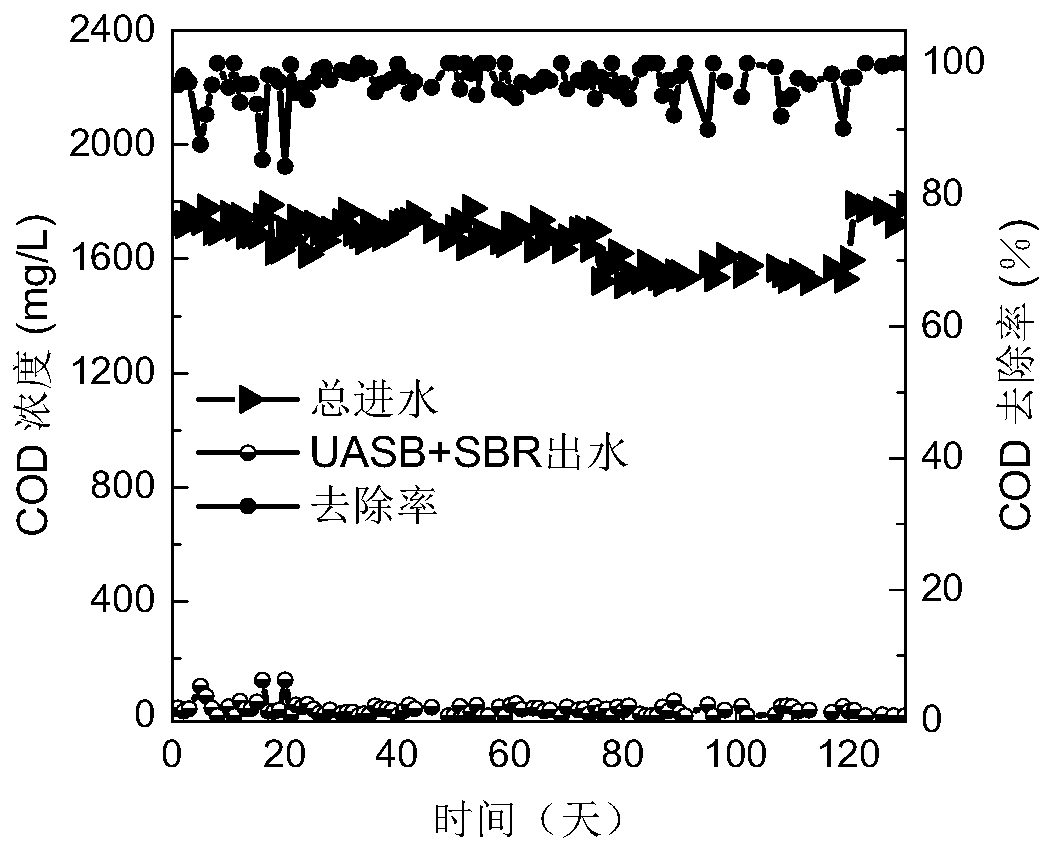

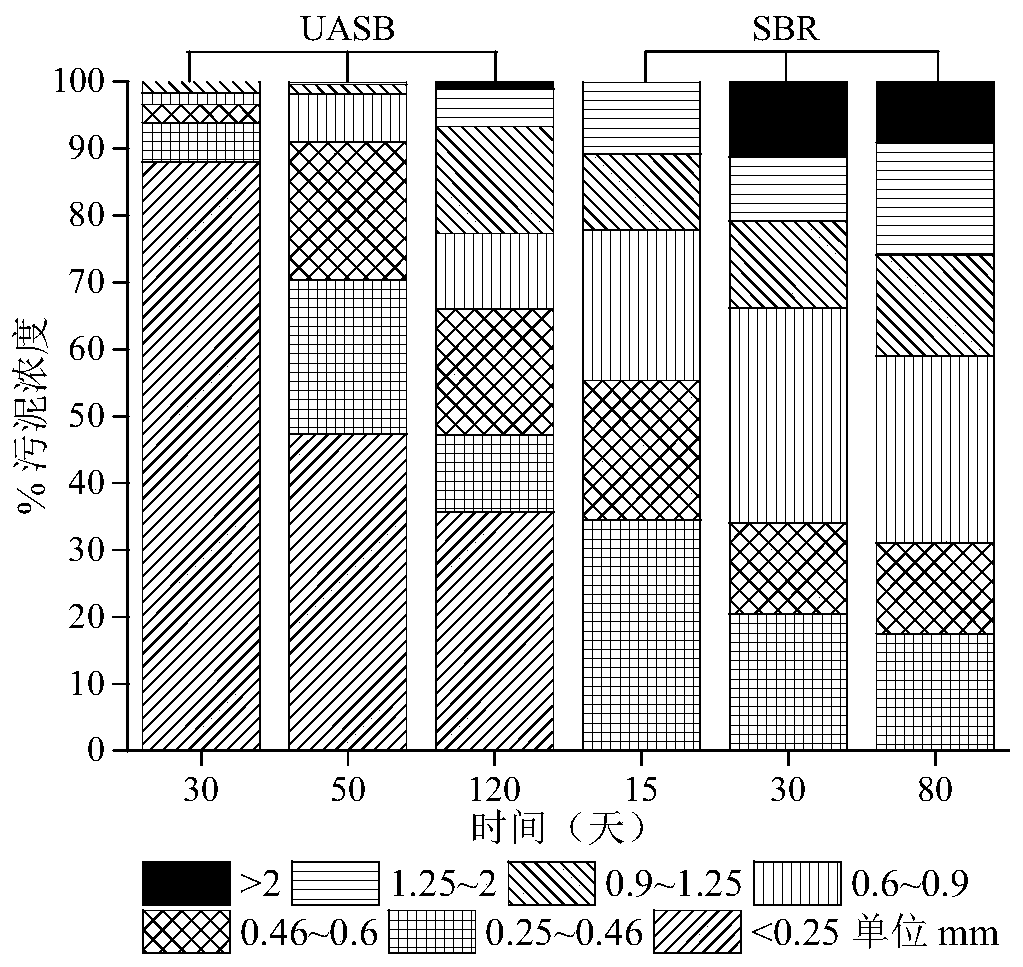

[0148] The treatment object of this embodiment is oily wastewater from heavy oil refineries. After dilution treatment and deoiling pretreatment, the oily wastewater will have an oil content of 250-280 mg / L, COD of 1500-2500 mg / L, and ammonia nitrogen of 8- 25mg / L of refinery wastewater to be treated. According to the volume of UASB and SBR, the amount of treated water in this implementation is 1.8m 3 / d.

[0149] The first influent is the diluted product of refinery wastewater to be treated, which is used for the cultivation and domestication of anaerobic granular sludge. The oil content of the first refinery wastewater is 120mg / L, and the COD is 500-600mg / L;

[0150] The second influent is the diluted product of refinery wastewater to be treated, which is used for the cultivation and domestication of aerobic granular sludge. The oil content of the second influent is 70mg / L, and the COD is 200-300mg / L;

[0151] The present embodiment comprises the following steps to the bioc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com