Preparation process of negative ion environment-friendly degradable vacuum blister glue

A vacuum blister and preparation process technology, which is applied in the field of anion-friendly and degradable vacuum blister glue preparation technology, can solve problems such as uneven heating, large material size gap, and insufficient environmental protection, and achieve optimal degradability, enhanced performance, and Effects that are easy to use in batches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

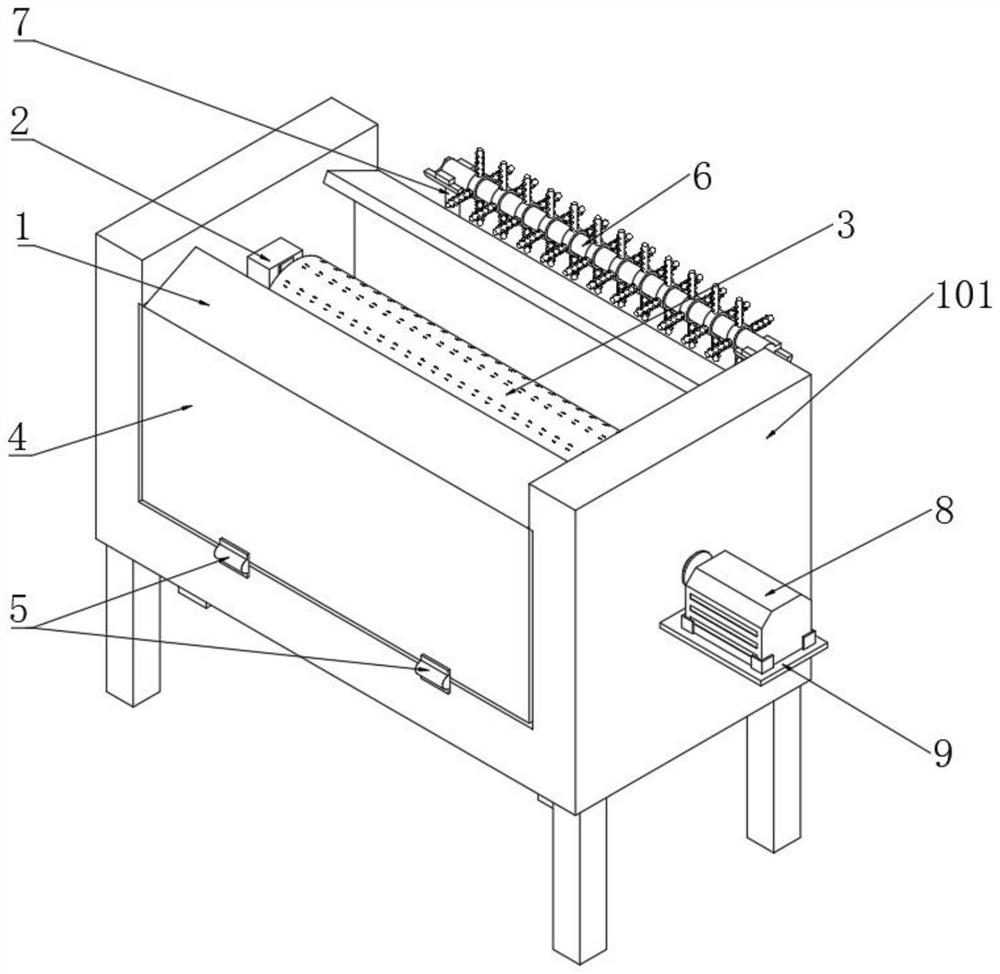

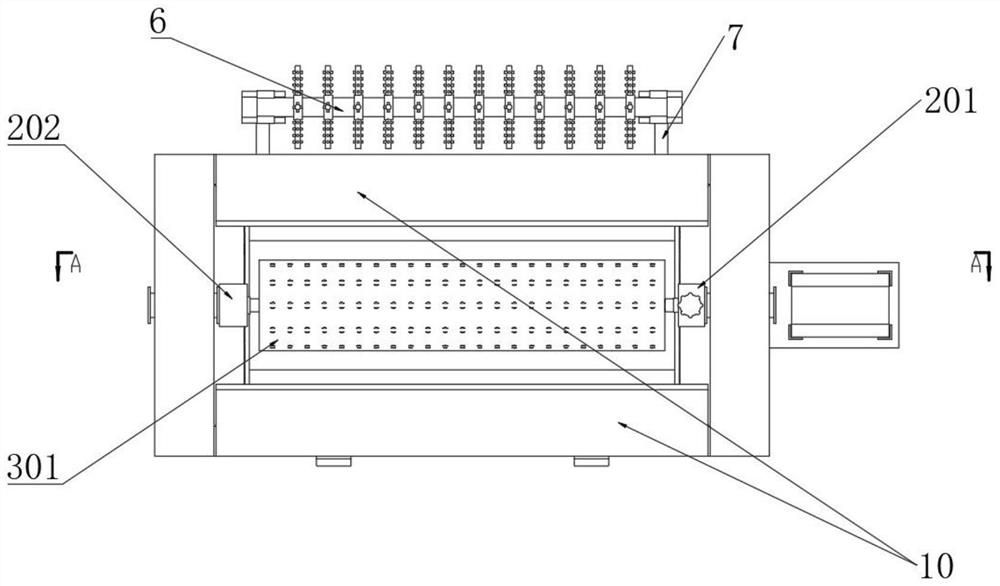

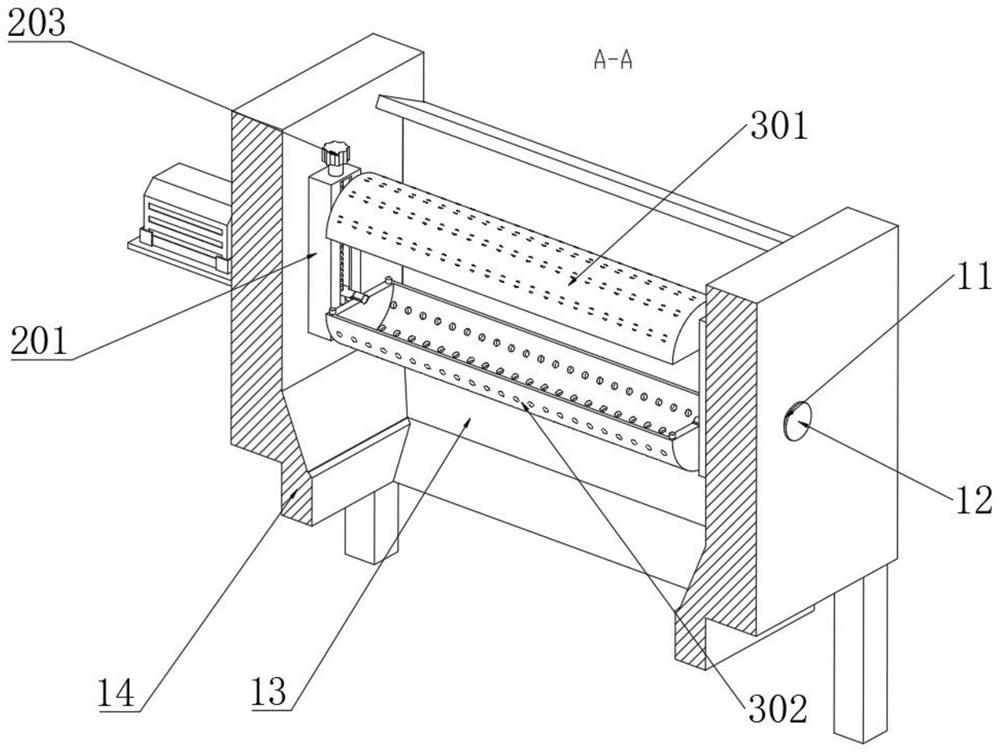

[0035] Such as Figure 1-10 As shown, the glue preparation process of negative ion environment-friendly degradable vacuum suction plastic includes the following steps:

[0036] S1: The material is preheated and liquefied, and the constituent materials of the vacuum absorbing plastic are pretreated first. The constituent materials of the vacuum absorbing plastic include: thermoplastic polyurethane elastomer rubber, thermoplastic polyurethane elastomer rubber, PUD emulsion, water-based blocked isocyanate, water-based sealed Isocyanate, wherein the thermoplastic polyurethane elastomer rubber is placed in the screening assembly 3, and then the auxiliary device 1 is used to screen the particle size of the material and the larger particles are segmented, and then the processed vacuum plastic composition material is subjected to high temperature Heating, so that the vacuum plastic composition material changes from solid to liquid;

[0037] S2: Catalytic reaction of materials, put th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com