High efficiency bio-augmentation treatment method for printing and dyeing wastewater

A printing and dyeing wastewater, bio-enhancing technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, adsorbed water/sewage treatment, etc., can solve the problem of poor shock load resistance, unstable effluent quality and poor denitrification effect. and other problems, to achieve the effect of enhancing the anti-shock load capacity, enhancing the sedimentation performance, and enhancing the denitrification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

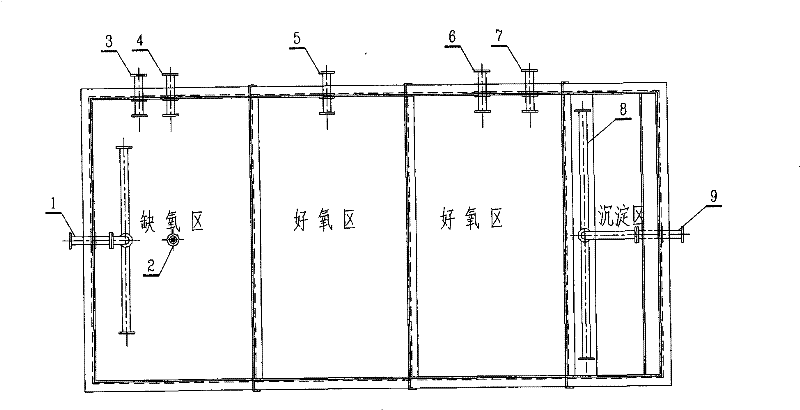

[0021] After pretreatment, the wastewater from a printing and dyeing enterprise enters the high-efficiency A / O pool through the water inlet pipe (self-flowing or pumping) after being hydrolyzed and acidified in a self-flowing way. The COD is 464.4mg / L, and the NH 3 -N is 35.34mg / L, TN is 42.33mg / L, TP is 6.1mg / L, and the chromaticity is 260 times. Add methanol to it, the dosage of methanol is 20~30mg / L in the front section, and 20~30mg / L in the back section. The dosage in the oxygen zone 2 / 3 is mg / L. The high-efficiency A / O pool adopts 100% external return (through the external return pipe) and 300% internal return (through the internal return pipe). Stirrer power is 12W / m 3 , the wastewater treated in the anoxic zone enters the aerobic zone, and the dosage of powdered activated carbon is 50mg / L. The residence time is 20h. Aeration (provided through the aeration tube) is provided according to the air-water ratio of 20:1. The wastewater treated in the aerobic zone enters t...

Embodiment 2

[0023] Other operations are as in Example 1. But do not add powdered activated carbon. The effluent quality COD is 178.3mg / L, NH 3 -N is 3.34mg / L, TN is 12.6mg / L, TP is 1.2mg / L, and the chromaticity is 120 times.

Embodiment 3

[0025] Other operations are as in Example 1. But methanol is added in the front section once. The effluent quality COD is 154.4mg / L, NH 3 -N is 3.34mg / L, TN is 32.4mg / L, TP is 0.9mg / L, and the chromaticity is 80 times.

[0026] Example 3

[0027] Other operations are as in Example 1. But the internal reflux ratio is 200%. The effluent quality COD is 144.4mg / L, NH 3 -N is 2.34mg / L, TN is 28.4mg / L, TP is 1.2mg / L, and the chromaticity is 90 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com