Method for large spur gear profile deviation in-site measurement adopting precise core rod measuring head

A mandrel and probe technology, applied in the field of large-scale gear measurement, can solve the problems of low measurement efficiency, large gear inertia, poor measurement conditions, etc., and achieve the effect of improving measurement efficiency and reducing length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

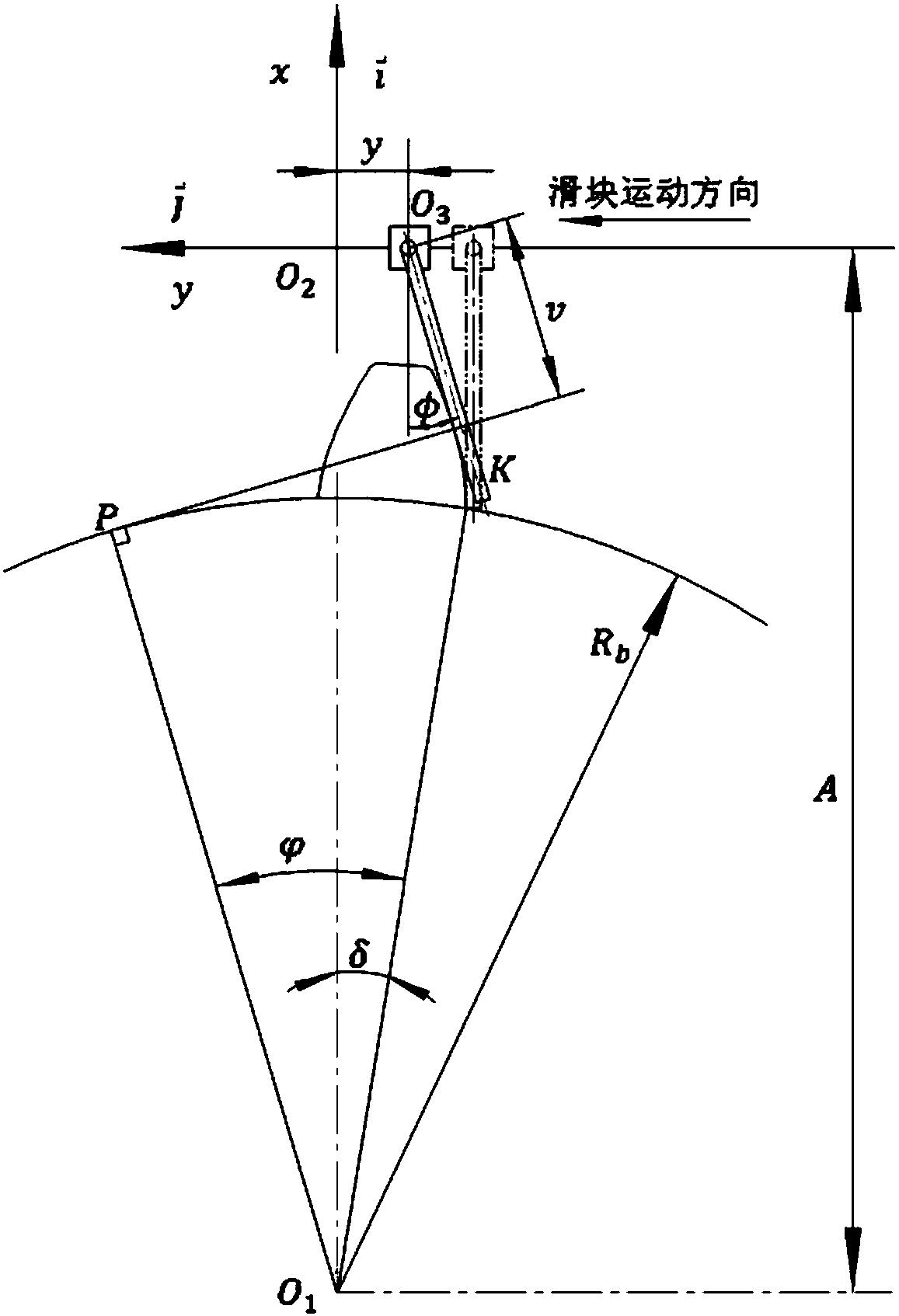

[0030] This embodiment discloses a method of using a precision mandrel probe to measure the profile deviation of a large spur tooth in situ, specifically:

[0031] (1) Determine the measured tooth profile of the tested gear, and select a certain tooth profile of the tested gear as the measured tooth profile;

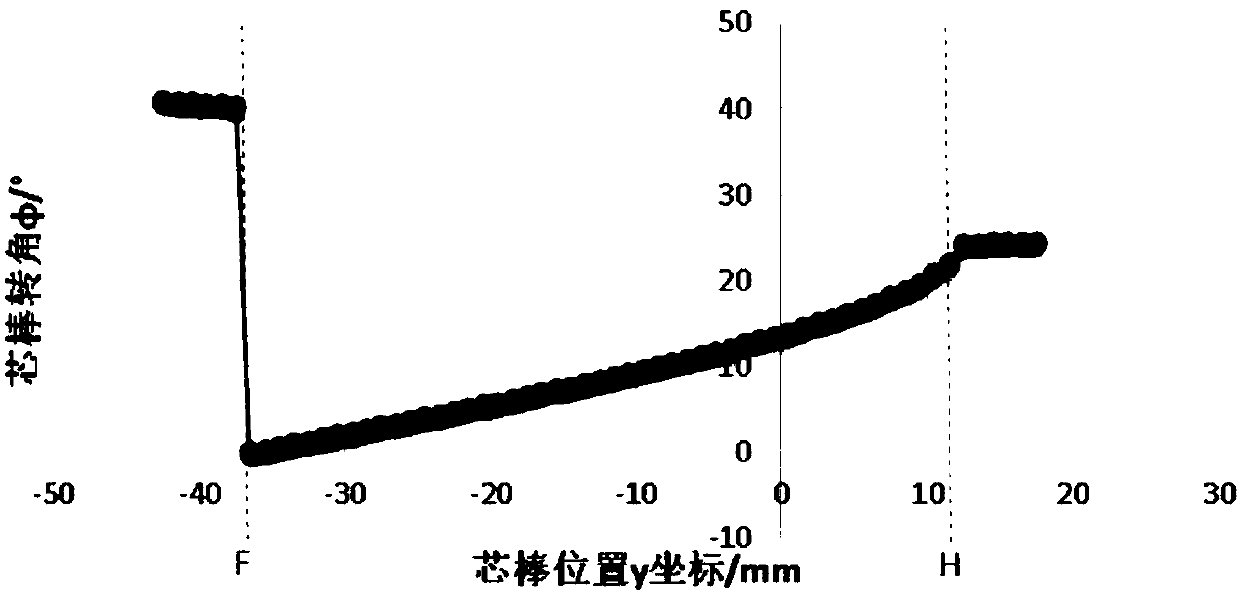

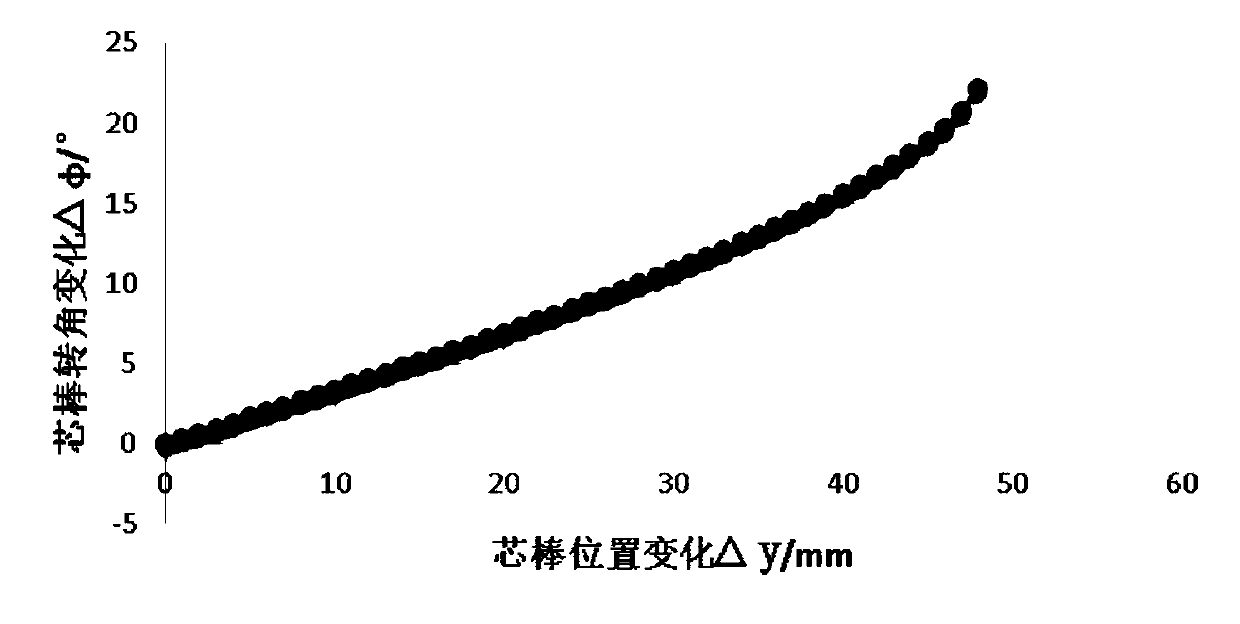

[0032] (2) Based on the end face of the ring gear and the base cylinder of the large gear, locate and install the precision mandrel probe. The gear to be tested is fixed, and the slider is moved. The mandrel probe enters the measuring tooth groove, and the mandrel probe The head is not in contact with the tooth profile. This position is called the tooth profile measurement zero position. The mandrel probe can move along a straight line that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com