Underground gas storage well safety status grade evaluation method

A level assessment and safety level technology, applied in the direction of measuring devices, instruments, fluid tightness testing, etc., can solve the problems of underground gas storage wells such as lack of pertinence, poor applicability, and lack of operability, so as to achieve economical efficiency Effects related to safety, ensuring safe use, and avoiding over-inspection or under-inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

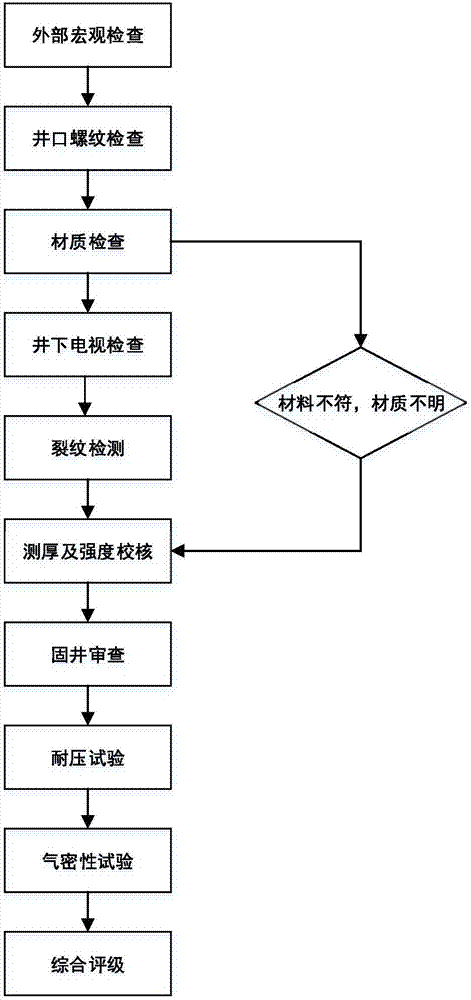

[0082] An underground gas storage well, through external macroscopic inspection, there is no leaking or sinking well, the safety status of the project is grade 1; after the inspection of the wellhead thread, 2 threads are damaged, the safety status of the project is grade 4; Inspection, there is no problem, the safety status of the project is level 1; underground TV inspection, it is found that the scale is fully covered without any rust, the safety status of the project is level 1; the internal inspection of the gas storage well shows that there is no crack, the The safety status level of the project is level 1; the ultrasonic thickness measurement of the gas storage well, after passing the 3-year residual wall thickness strength check, the safety status level of the project is level 4; the inspection of the cementing data found that no cement cementing was carried out but the cementing was carried out. Reinforced concrete is reinforced and passed the reinforcement strength ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com