Portable ultrasonic flaw detection and scanning device capable automatically crawling on inner wall of pipeline and application method of portable ultrasonic flaw detection and scanning device

An automatic crawling and scanning device technology, applied in the direction of material analysis, measuring devices, instruments, etc. using sound waves/ultrasonic waves/infrasonic waves, can solve problems such as difficult to scan the steel pipe surface, dangerous operation, long time, etc., to reduce labor Intensity, enhanced security, and reduced inspection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

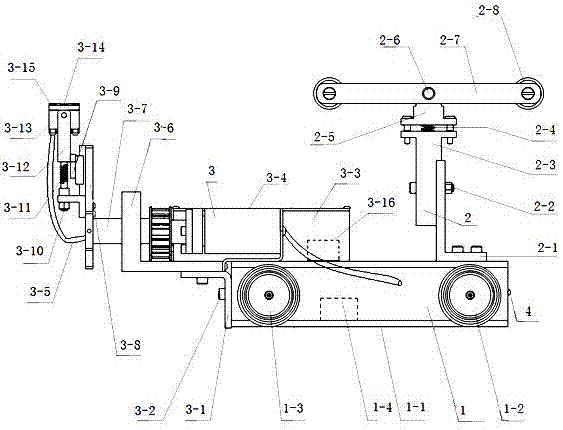

[0010] Taking the pipe to be tested as a 219▬244mm steel pipe, the maximum crawling distance of the present invention is 7.5m. The crawling motors 1-4 and the rotating motors 3-16 all use geared motors. The speed ratio: crawling 1367:1; rotating 188:1, the main water pipe The diameter is 6mm, the ultrasonic probes 3-14 are 5MHz, K3 type oblique probes, and the direction of the sound beam is perpendicular to the axis of the steel pipe as an example to further illustrate with the accompanying drawings.

[0011] Such as figure 1 , 2 As shown, the present invention is an aluminum alloy body, including a crawler 1, a support structure 2, an automatic coupling flaw detection device 3, and a remote control component 4. The crawler 1 includes a box body 1-1, wheels 1-2, and axles 1- 3. The crawling motor 1-4, the crawling motor 1-4 is fixed in the box body 1-1, the two wheel shafts 1-3 are fixed on the box body 1-1, one of which is connected with the crawling motor 1-4 shaft, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com