An easy-to-open skylight optical cable and its manufacturing method

A fiber optic cable and optical fiber loose technology, which is applied in the manufacturing field of easy-open skylight cable and easy-open skylight cable, can solve the problems of not being able to accurately grasp the position and depth of the skylight of the cable, damaging the cable, and easily cutting the optical fiber in the cable, so as to reduce the damage of the fiber Events, difficulty reduction, and effects of avoiding fiber damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

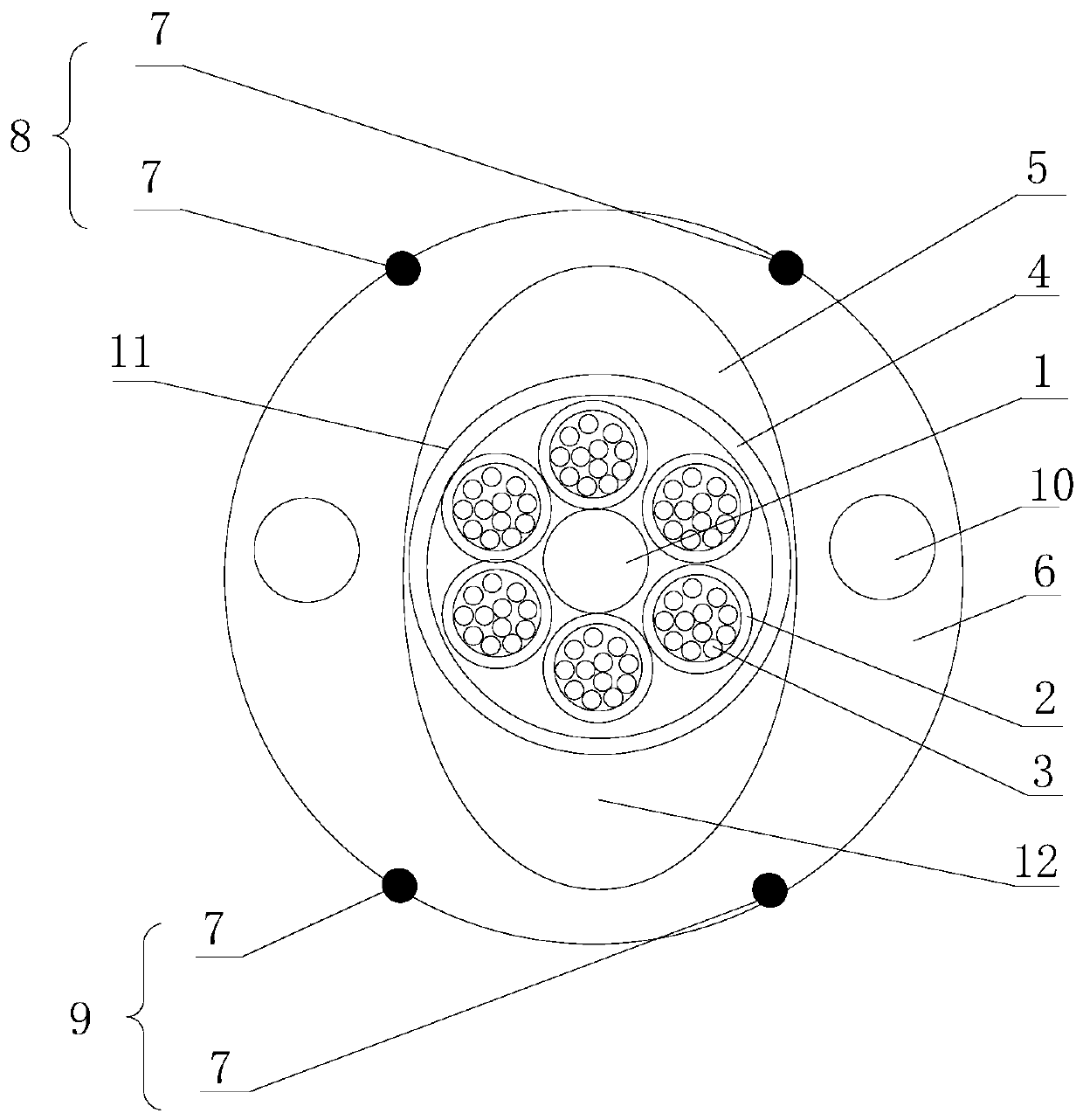

[0042] see figure 1 As shown, the present invention provides an easy-to-open skylight cable, comprising an outer sheath 6 and an inner layer 11, the outer sheath 6 is hollow to form a housing cavity 5, and the housing cavity 5 has a long end and a short end, and the inner layer 11 is accommodated in The housing chamber 5, and the inner layer 11 is provided with an optical fiber unit, and a gap 12 is formed between the long end of the housing chamber 5 and the outer wall of the inner layer 11, and the inner layer 11 is clamped at the short end by the inner wall of the outer sheath 6 , the outer surface of the outer sheath 6 is provided with at least one pair of identification lines 7 extending along the cable length direction of the outer sheath 6, and the position of the pair of identification lines 7 is set so that on the cross section of the optical cable, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com