Fault Monitoring Method for Multidirectional Kica Batch Process Based on Independent Subspace

An independent subspace and fault monitoring technology, applied in program control, electrical test/monitoring, test/monitoring control system, etc., can solve problems such as insignificant monitoring effect and decreased monitoring rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0122] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

[0123] A kind of multi-directional KICA intermittent process fault monitoring method of independent subspace division of the present invention, comprises the following steps:

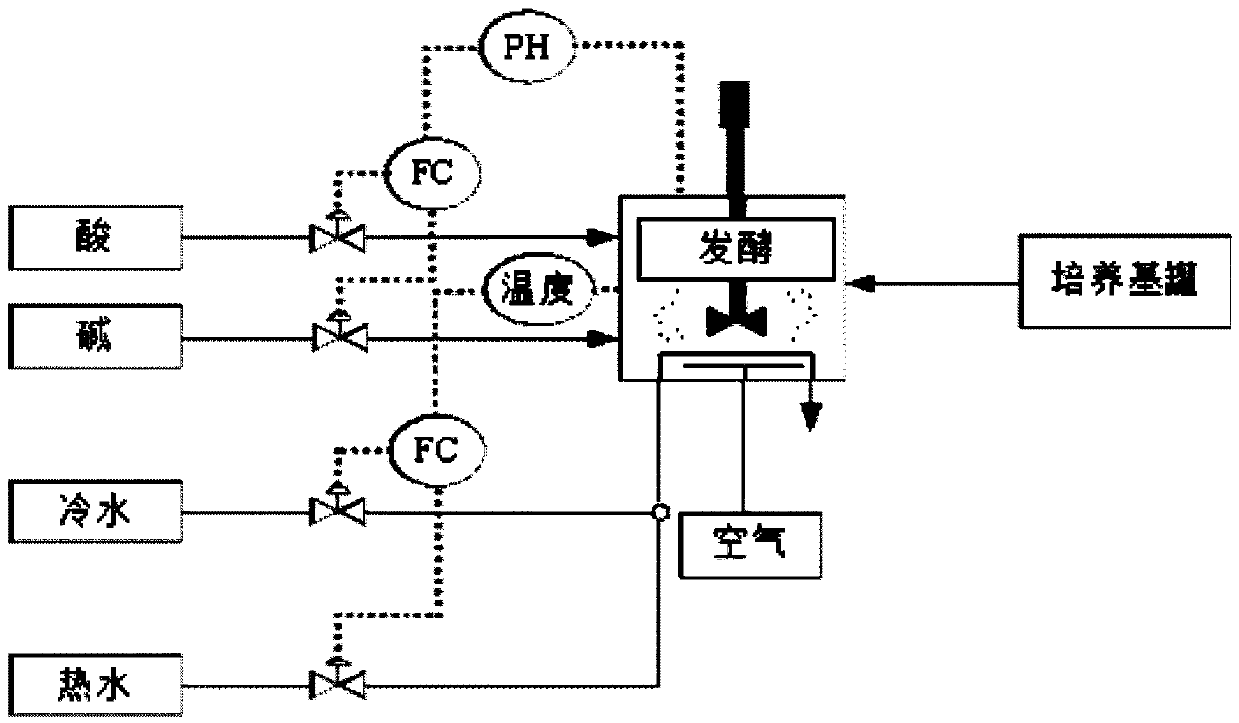

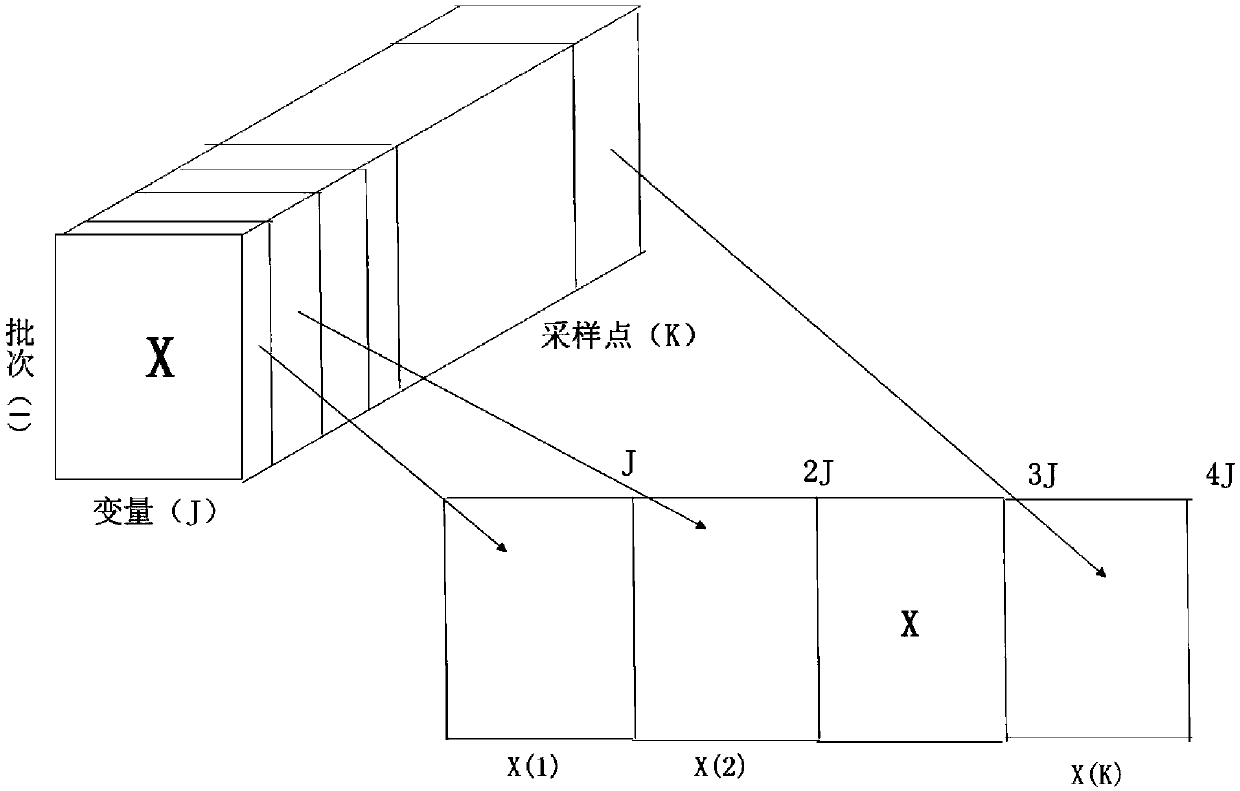

[0124] 1) Collect the 3D data X (I×J×K) of the intermittent process, apply multi-directional KICA, and expand the 3D data into 2D data in batches for processing;

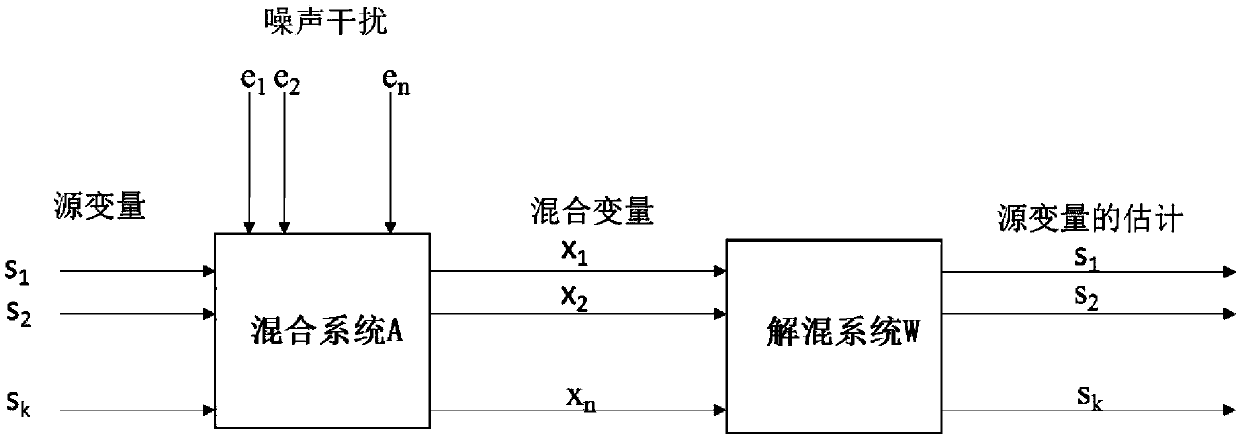

[0125] 2) Carry out offline modeling of the two-dimensional data expanded by batches, add kernel techniques on the basis of ICA, map the nonlinear data to the high-dimensional feature space, and then perform linear processing in the high-dimensional space;

[0126] 3) Apply T 2 and SPE statistics to monitor the process online; summarize the fault information obtained from each sub-data, and calculate whether the statistics exceed the limit.

[0127] In step 1), such as figure 2 As shown, the three-dimensional pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com