Display screen, display device and mobile terminal

A technology for display screens and display parts, which is applied in the directions of identification devices, printing devices, projection devices, etc., and can solve problems such as poor camera lens installation, affecting shooting effects, and camera lens shaking, so as to improve the firmness of engagement and the stability of installation The effect of reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

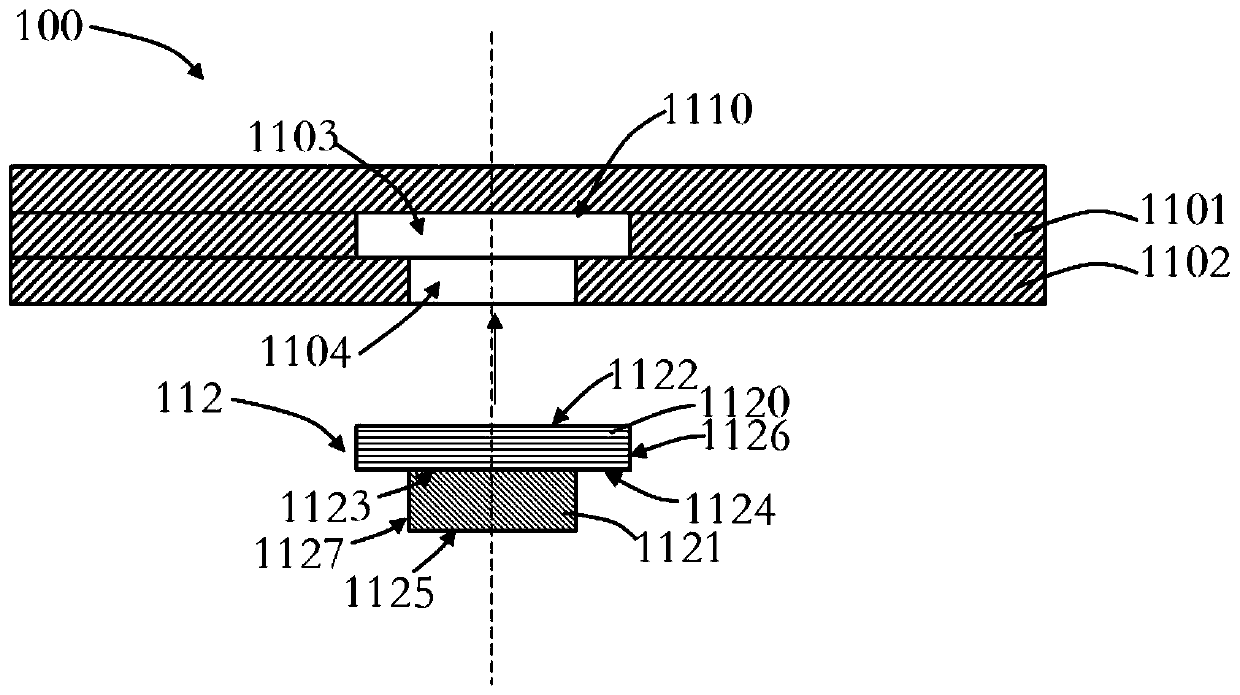

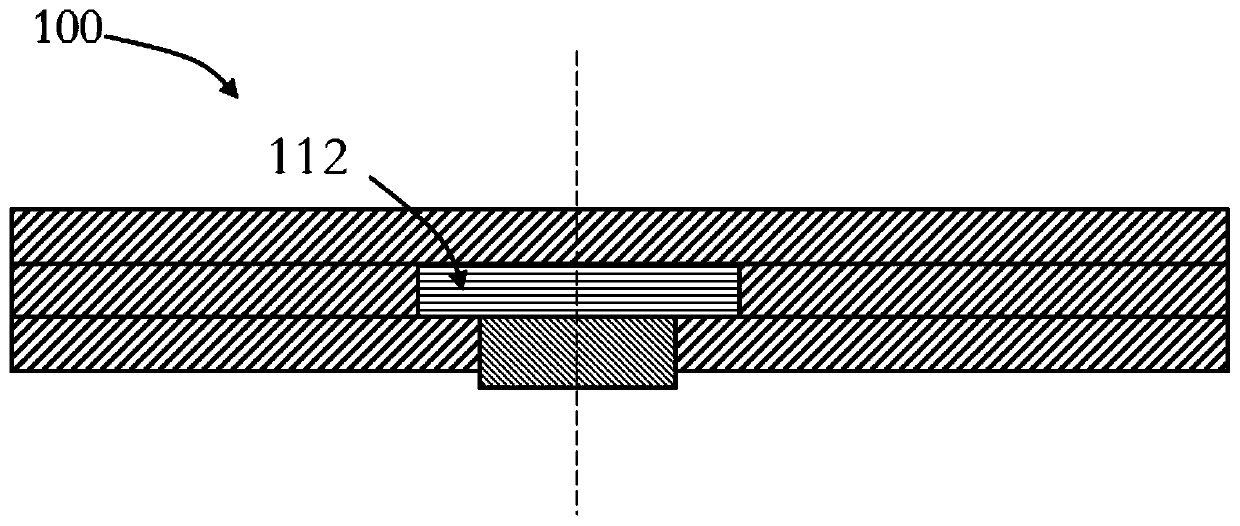

[0050] see Figure 5 As shown in FIG. 7 , the first groove 113 is disposed on the second bottom surface 1125 , and the first groove 113 is a square groove, and the first protrusion 114 is a square protrusion. Such a structural design can avoid rotational sliding between the first groove 113 and the first protrusion 114, and can further improve the alignment accuracy and installation of the camera lens 220 and the insert 112. Firmness.

no. 2 example

[0052] see Figure 8 , the first groove 113 is disposed on the second bottom surface 1125 , and the first groove 113 is provided with a concave arc surface 1131 . The first protrusion 114 has a convex arc surface 1141 matching the concave arc surface 1131 . With such a structural design, on the one hand, the concave arc surface 1131 is engaged with the convex arc surface 1141, so that the camera lens 220 is firmly installed under the display screen 100; The curved surface 1141 can be used as a concave light incident surface of the camera lens 220, and the concave light incident surface can converge light on the camera lens 220, that is, while the first protrusion 114 is used as an engaging part, It is also used as a lens element to optimize the shooting effect of the camera lens 220 .

no. 3 example

[0054] see Figure 9 , the first groove 113 is disposed on the second bottom surface 1125 , and the first groove 113 is provided with a convex arc surface 1132 . The first protrusion 114 has a concave arc surface 1142 matching the convex arc surface 1132 . With such a structural design, on the one hand, the concave arc surface 1142 is engaged with the convex arc surface 1132, so that the camera lens 220 is firmly installed under the display screen 100; The curved surface 1142 can be used as a convex light incident surface of the camera lens 220, and the convex light incident surface can diverge the light on the lens element of the camera lens 220, that is, the first protrusion 114 serves as an engaging At the same time, it also serves as a lens element to optimize the shooting effect of the camera lens 220.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com