Reed type fixture

A reed type, clamp technology, applied in coupling devices, conductive connections, electrical components, etc., can solve the problems of damage to the surface of battery tabs, inconvenient replacement, etc., and achieve high crimping reliability, convenient replacement operation, and contact resistance. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

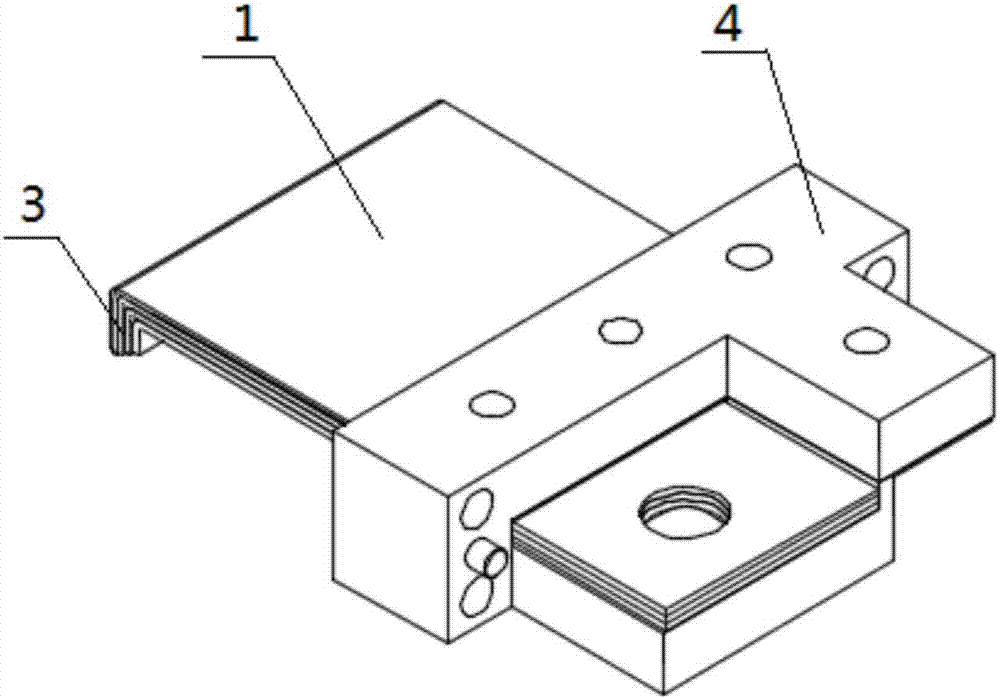

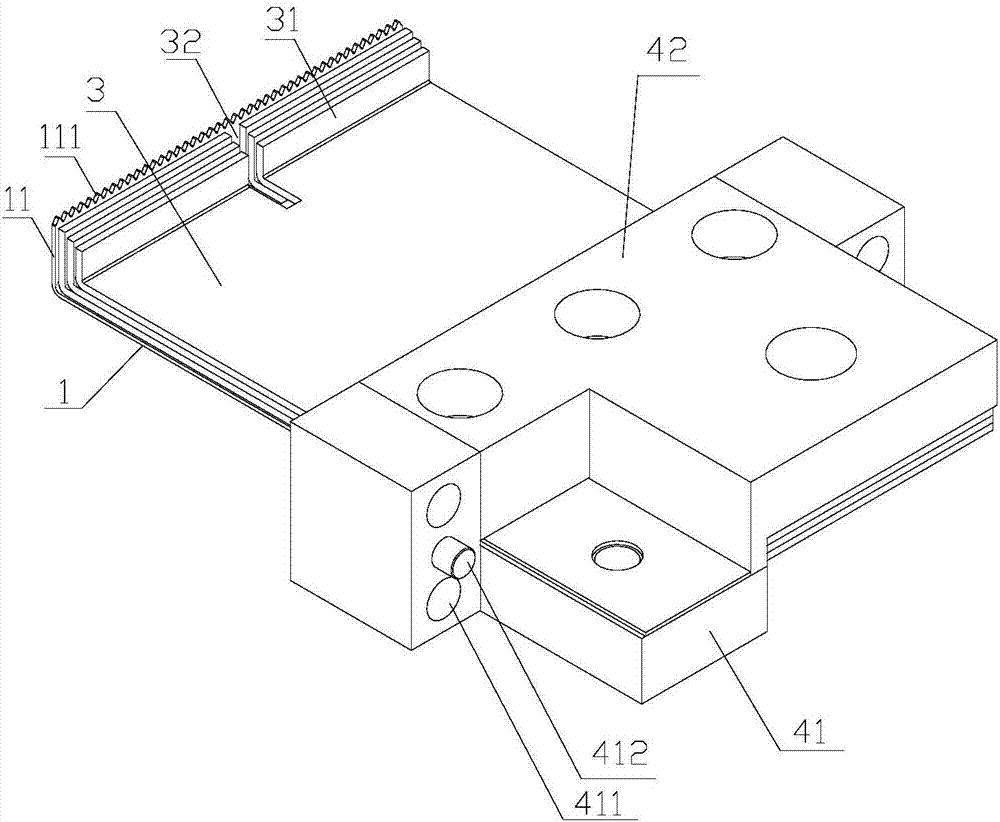

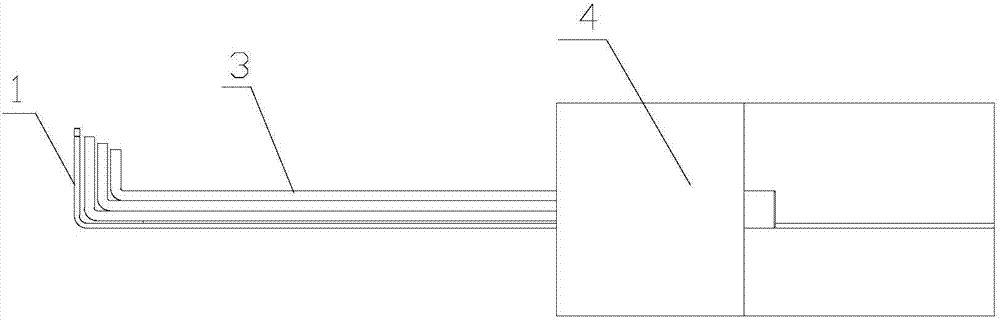

[0023] Embodiment 1 The reed clamp according to the present invention includes a voltage sheet 1, an insulating sheet 2, a plurality of current sheets 3 and a spring fixed injection molded part 4, and the front part of the voltage sheet 1 is folded down to form a first turn folded edge 11, and the edge of the first folded edge 11 is set as a zigzag 111; the front portion of the current sheet 3 is folded down to form a second folded edge 31, and the first folded edge 11 The height is consistent with the height of the second folded edge 31, forming a clamping piece for clamping the tab; the front part of the current sheet 3 is divided into left and right parts by an axial groove 32; the voltage The sheet 1, the insulating sheet 2 and the current sheet 3 are sequentially stacked layer by layer from top to bottom to form a layered structure; the spring fixed injection molding part 4 includes an upper injection molding part 41 and a lower injection molding part 42, and the upper inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com