A brushless DC motor for an electric vehicle

A brushed DC motor and electric vehicle technology, applied in the field of electric vehicles, can solve the problem of large commutation torque ripple, and achieve the advantages of reducing commutation torque ripple, high fault-tolerant operation capability and reliability, and avoiding the spread of faults. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

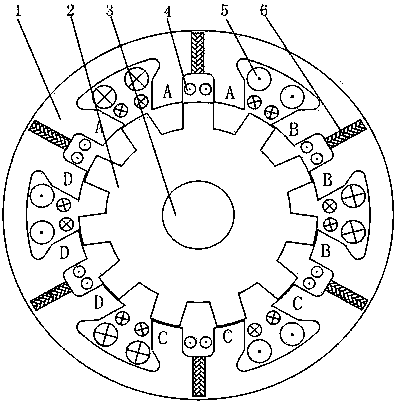

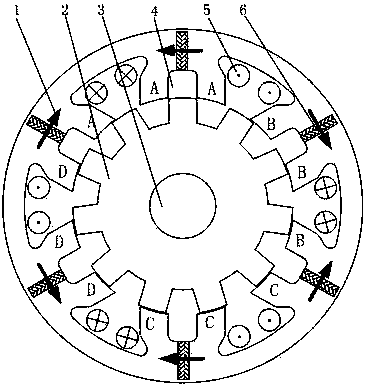

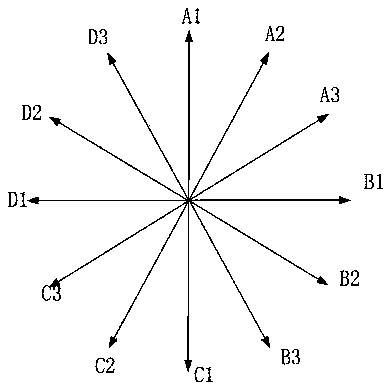

[0032] The accompanying drawings disclose, without limitation, the structural schematic diagrams of the preferred embodiments involved in the present invention; the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] figure 1 It is a structural schematic diagram of a brushless DC motor for an electric vehicle according to the present invention. The brushless DC motor of an electric vehicle comprises a stator core (1), a rotor core (2), an excitation winding (5), a permanent magnet (6), an armature winding (4) and a shaft (3), which is an inner rotor structure, The rotor core (2) is fixed on the shaft (3), and there are 11k uniformly distributed convex rotor poles on the rotor core (2), where k is a positive integer. In this embodiment, k=1.

[0034] The stator core (1) has 12k convex stator poles, the 12k stator poles are divided into 6k pairs of parallel stator poles, and the centerlines of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com