Flame-guard filter composed of a number of layer sequences, and arrangements of flame-guard filters and their use

A filter and layer sequence technology, applied in filtration and separation, dispersed particle filtration, fire rescue, etc., can solve the problems of high space requirements, high material input, limited application possibilities of flame protection filters, etc. Dangerous effect of ignition breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

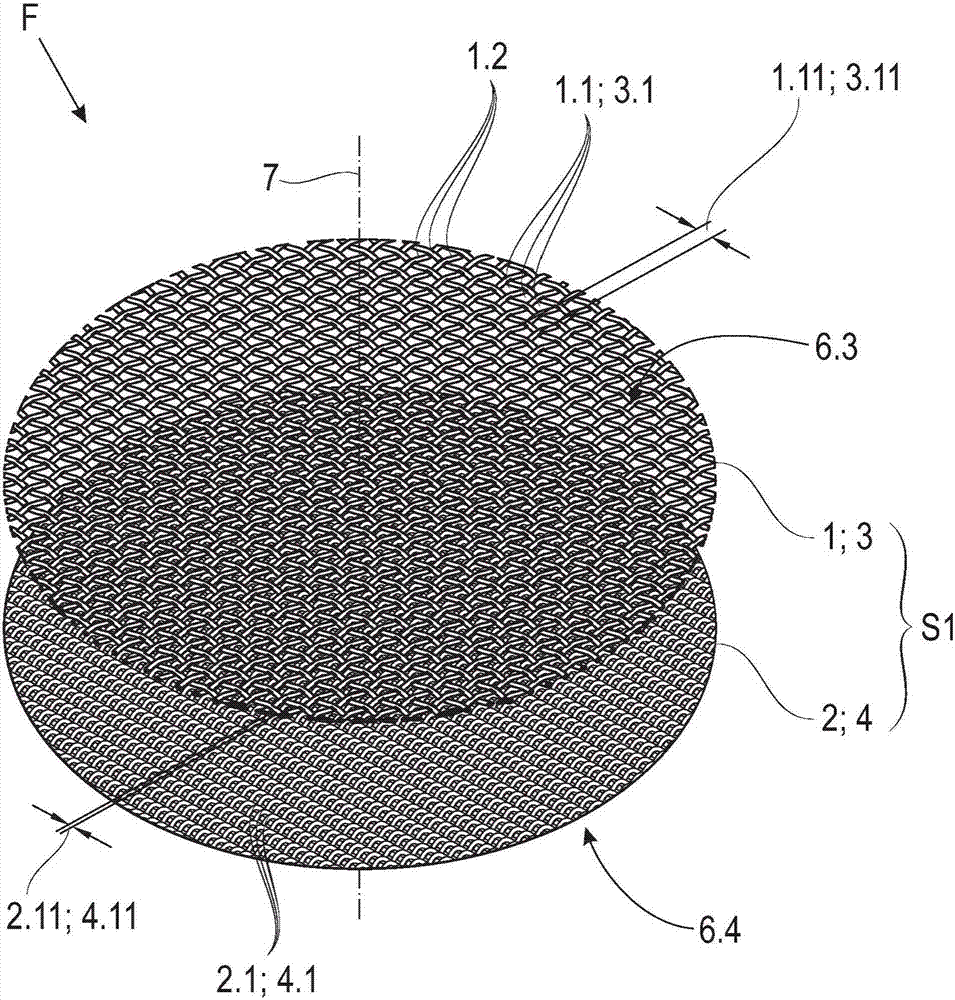

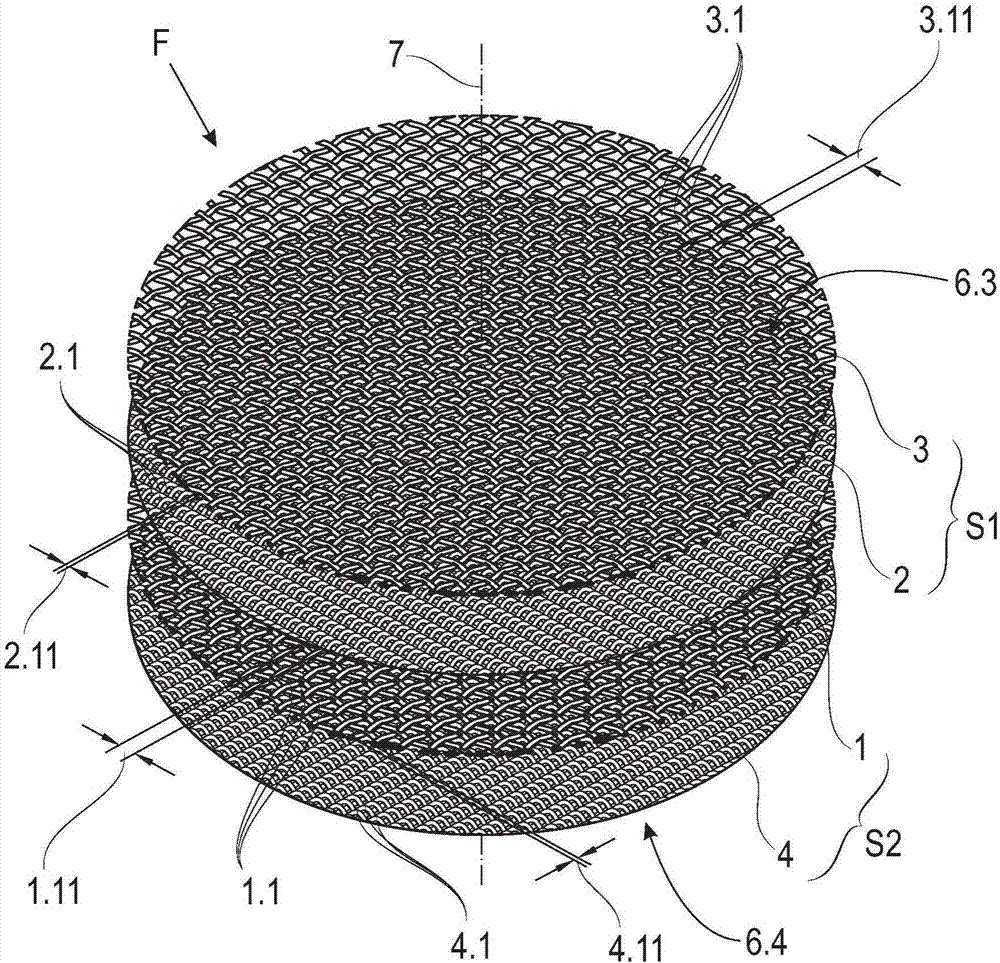

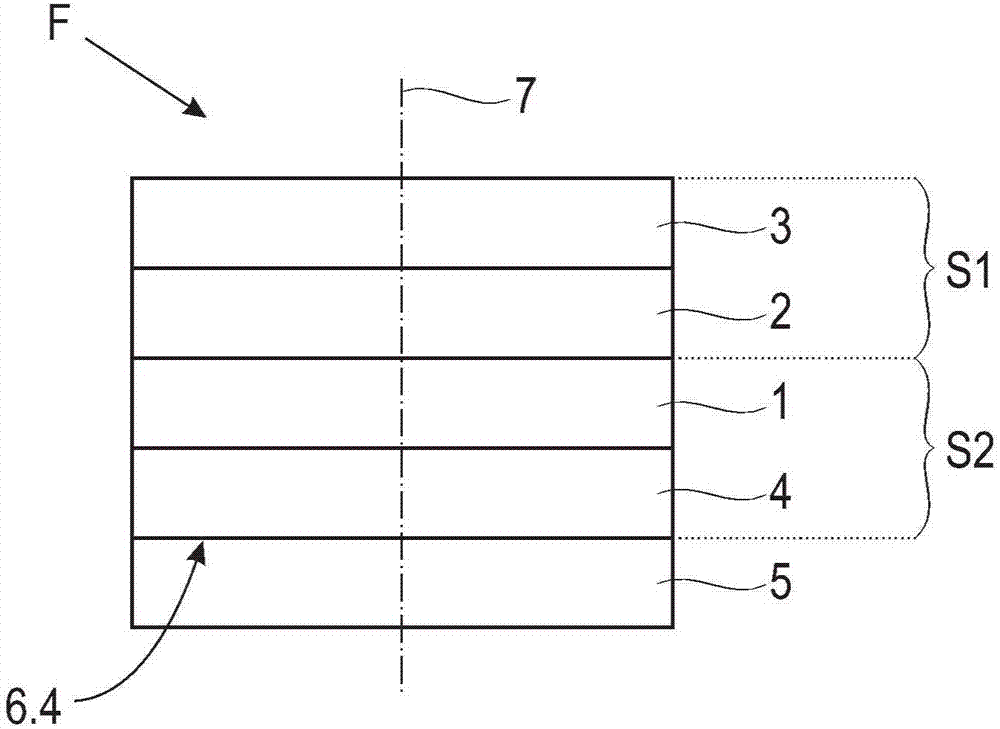

[0082] According to the flame protection filter F of the present invention in figure 1 An important element of the first embodiment schematically shown in is the first layer sequence S1 consisting of a first filter layer 1 and a second filter layer 2 along the are arranged one above the other along a common axis 7. The first filter layer 1 is formed from a metal wire fabric, has a circular cross section and has first openings 1.1. The first openings 1.1 are delimited by webs 1.2, all of the same size and of the same shape, and have a first opening width 1.11 of 400 μm as the clear width between two webs 1.2 running parallel to one another.

[0083] The second filter layer 2 is likewise formed from a metal wire fabric. The wire fabric is a plain woven wire mesh and has second openings 2.1 with a second opening width 2.11 of 150 μm.

[0084] The first filter layer 1 has free sides 6.3 and is henceforth referred to as the first end filter layer 3 . The second filter layer 2 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com