Clutch disc with torsional vibration damper

A technology of torsional vibration damper and clutch disc, which is applied in the direction of clutches, friction clutches, mechanical drive clutches, etc., can solve problems such as the deterioration of joint impact, and achieve the effect of saving components and long-term decoupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

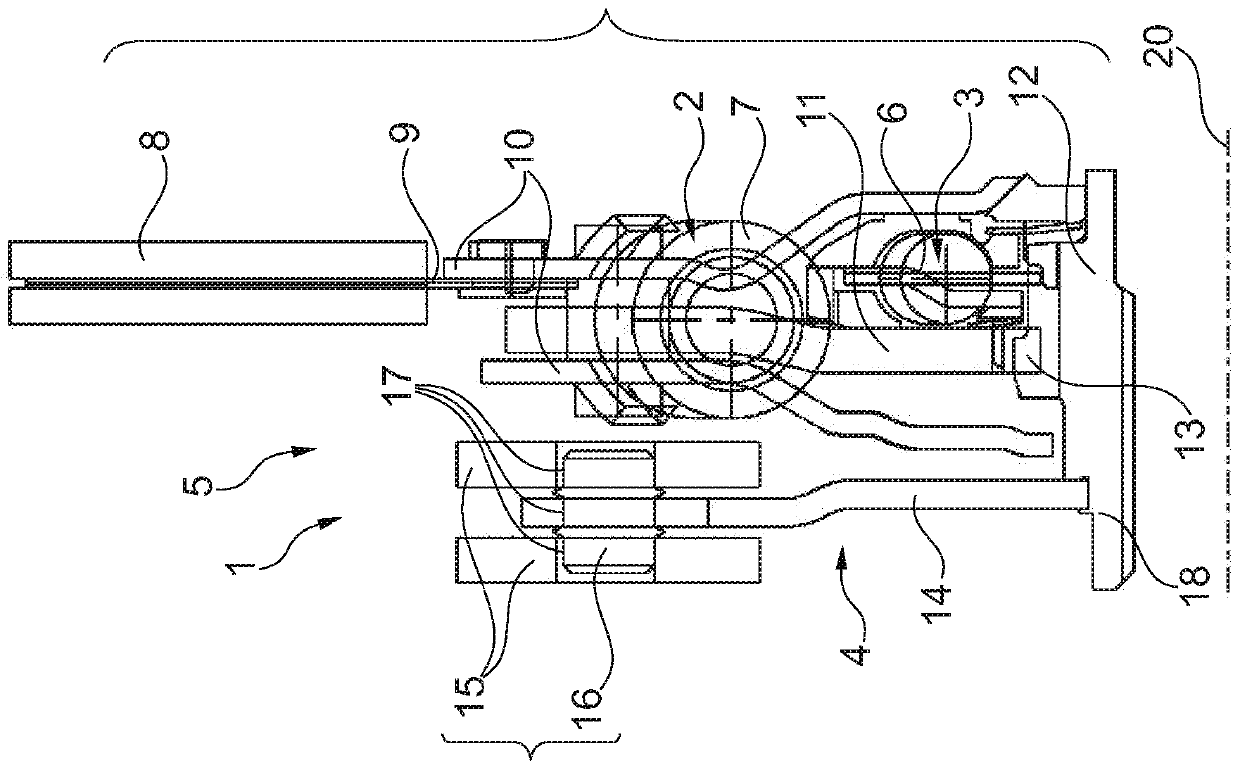

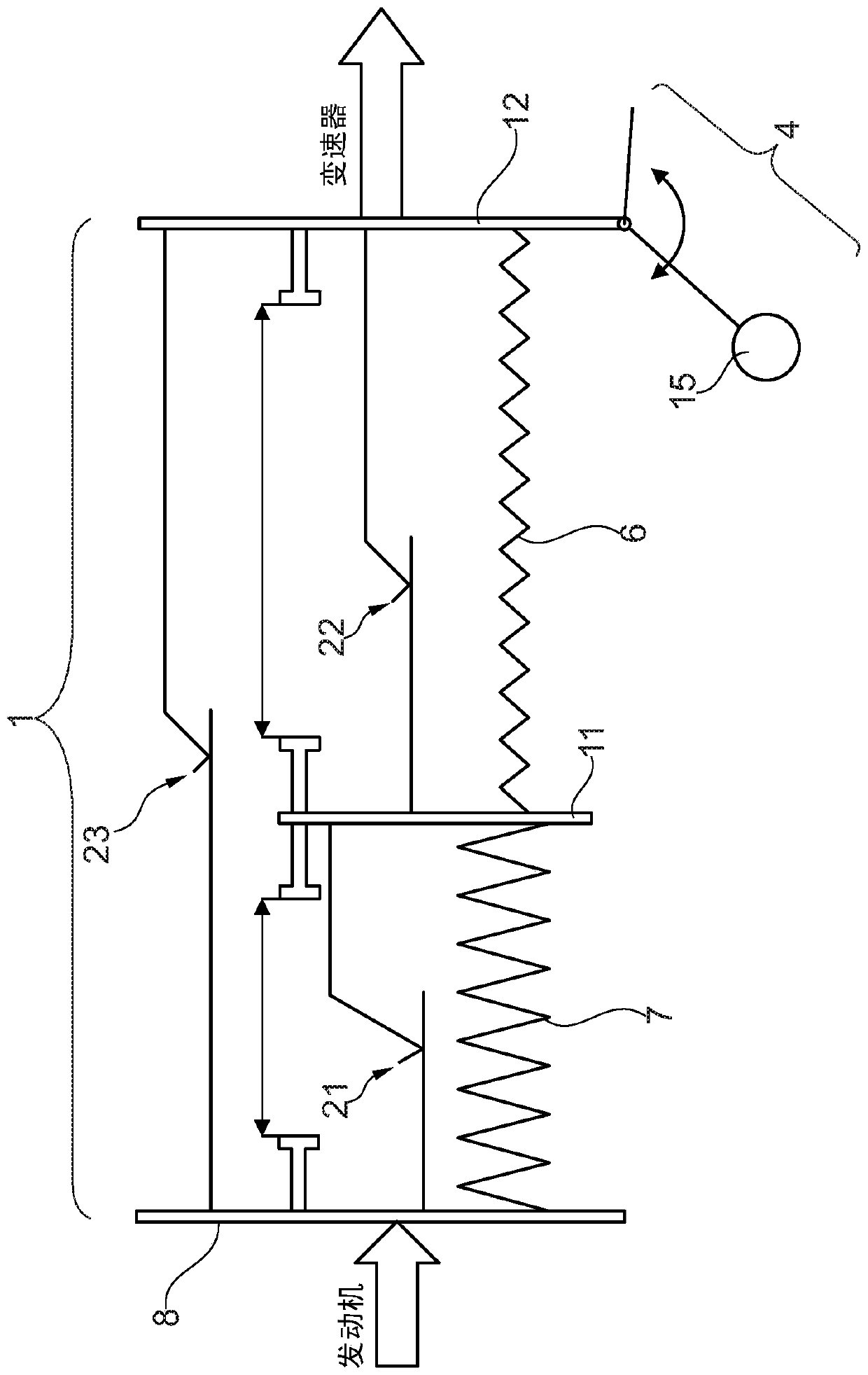

[0046] figure 1A half-sectional view of a clutch disk 1 according to the prior art is shown. The clutch disk 1 shown here is rotatable about an axis of rotation 20 , with which an axial direction or a radial direction or a circumferential direction is also defined. The axial direction is here along the axis of rotation 20 , the radial direction runs in a direction perpendicular to the axis of rotation 20 , and the circumferential direction is correspondingly defined on a trajectory around said axis of rotation 20 . This also applies correspondingly below to the illustrations in the other figures.

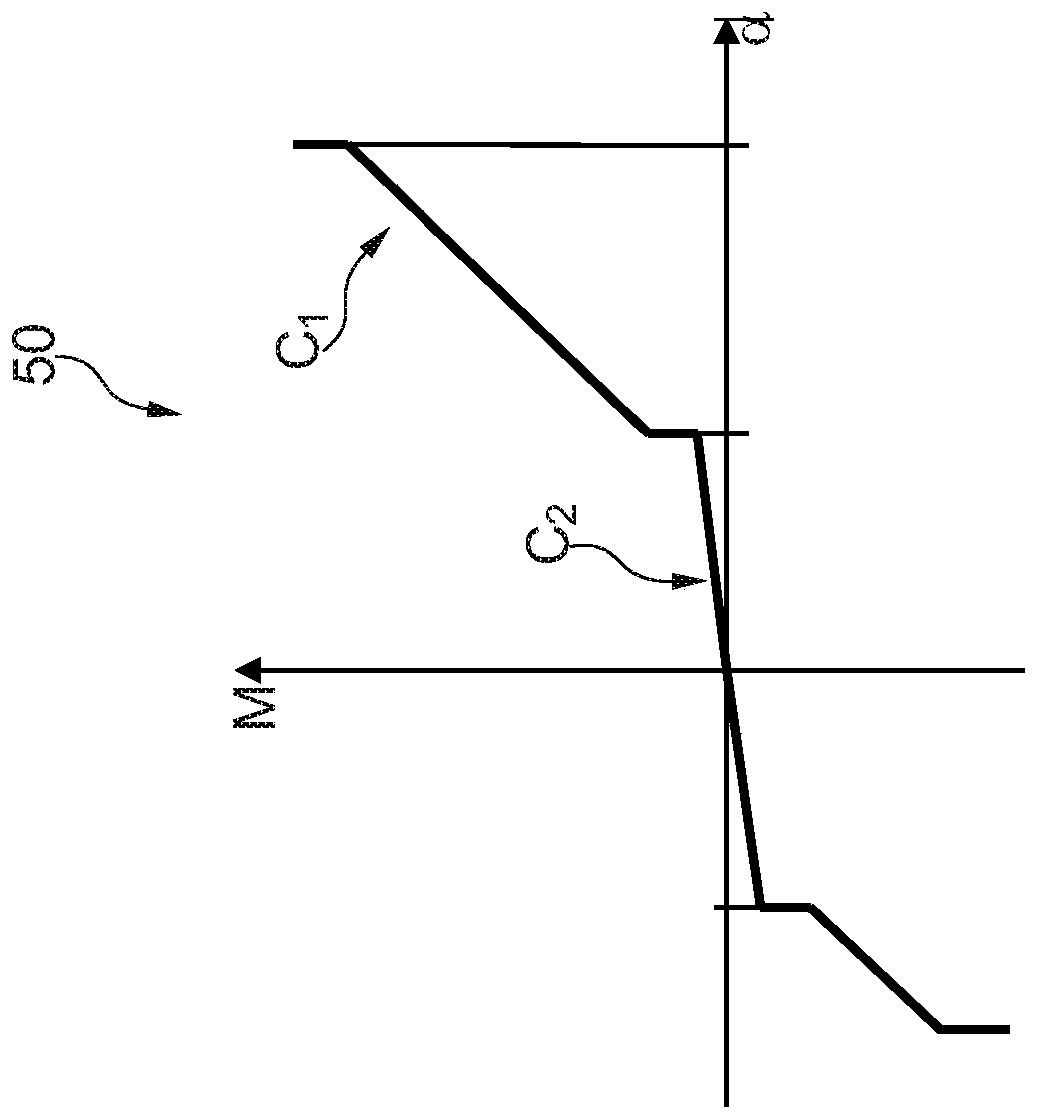

[0047] figure 2 The associated torque characteristic curve 50 of the torsional vibration damper of the clutch disk 1 is shown in a diagram. In this diagram the torque M is plotted as a function of the torsion angle α.

[0048] Here, a damper consisting of two spring dampers 2, 3 connected in series is arranged on the clutch plate 1, namely the first spring damper 2, which is de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com