Using soft-sensors in a programmable logic controller

A programming logic and soft sensor technology, applied in the direction of program control, program control, electrical program control, etc. in sequence/logic controllers, can solve problems such as complex, expensive, high development and customization costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

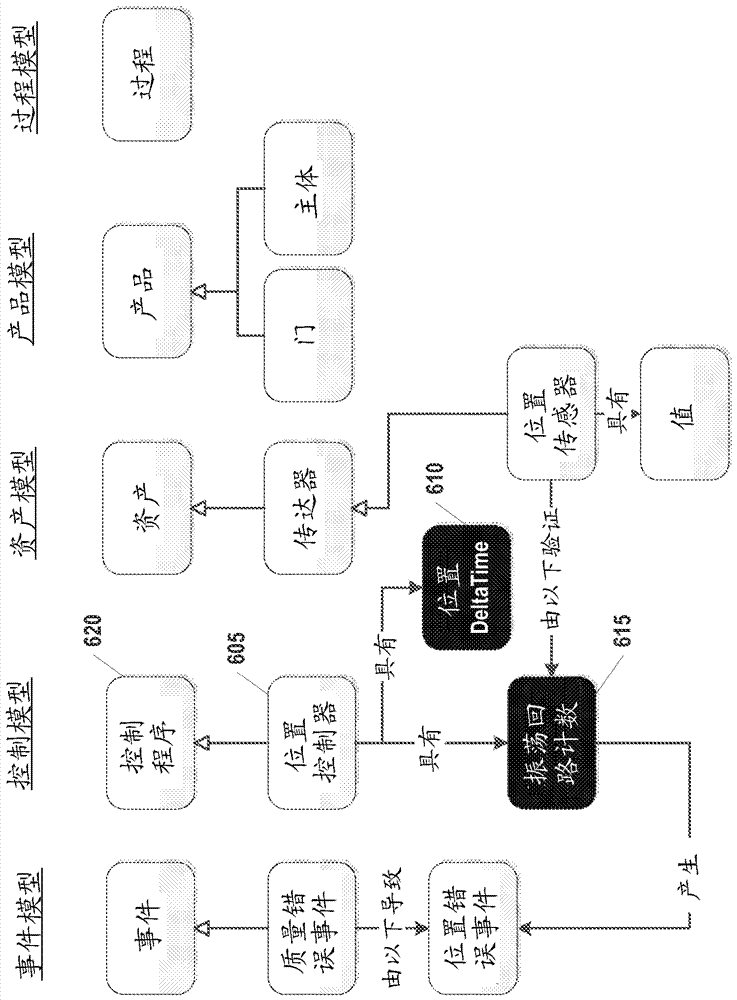

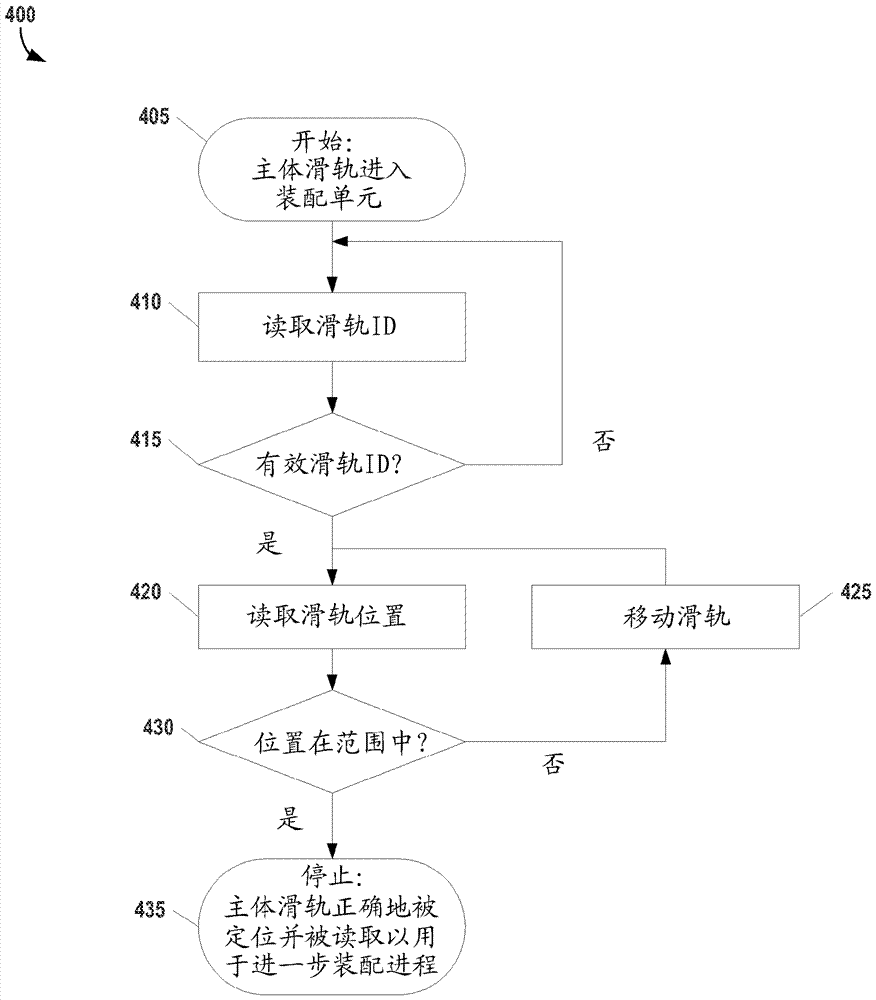

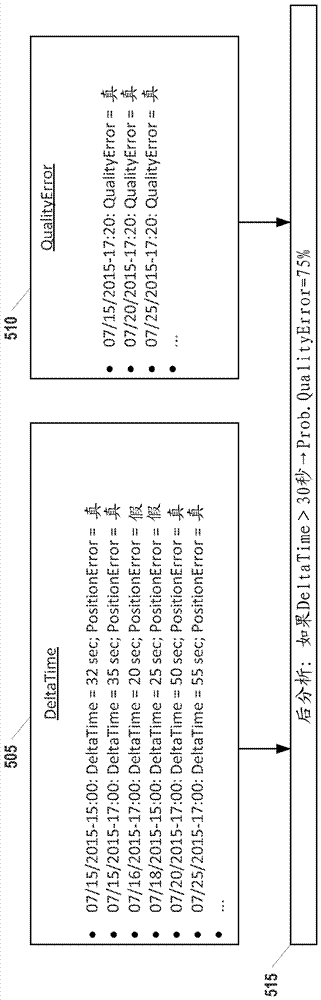

[0022] Described herein are systems, methods, and apparatus generally related to intelligent programmable logic controllers (PLCs) capable of monitoring and utilizing values associated with control level variables. These values (referred to herein as "soft sensors") are consumed at the control layer in conventional systems. That is, they are typically not used at higher levels of the automation system. Also, in some instances, the accessibility and use of such soft sensors within the controller itself may be limited. However, using the techniques described herein, soft sensor values can be captured during each scan cycle and used for further processing, such as generating data analysis or error analysis. The techniques described herein can be applied in various settings in which control systems are used, including, without limitation, industrial production environments.

[0023]Various embodiments of the invention are described in the context of a PLC that includes var...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com