A single tank multi-bed biogas fermentation device

A biogas fermentation and single-tank technology, which is applied to gas production bioreactors, biochemical instruments, waste fuels, etc., can solve problems such as uneven residence time, low organic load capacity, and uneven distribution, and achieve improved raw material utilization. Increase the appropriate concentration to ensure the effect of fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

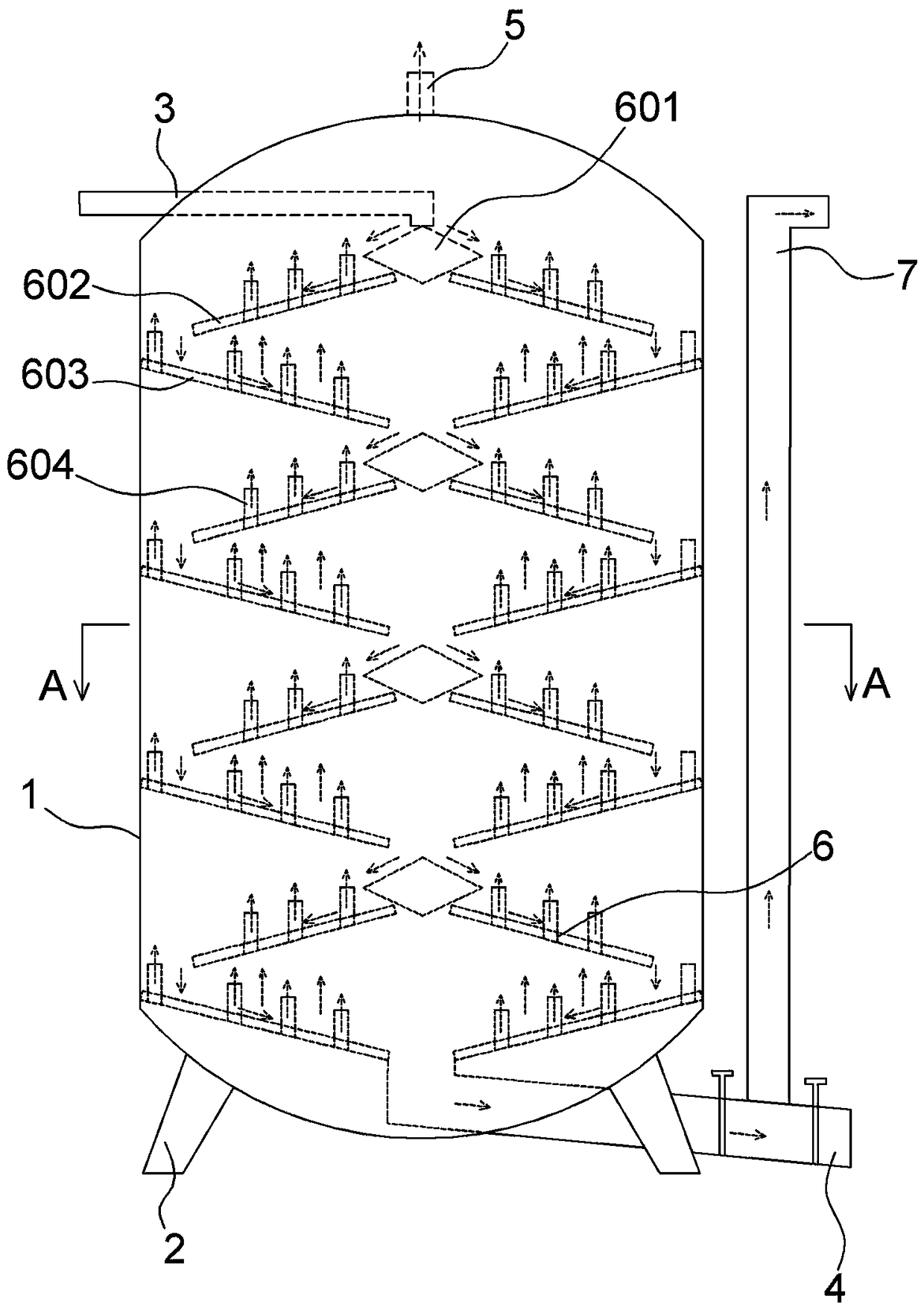

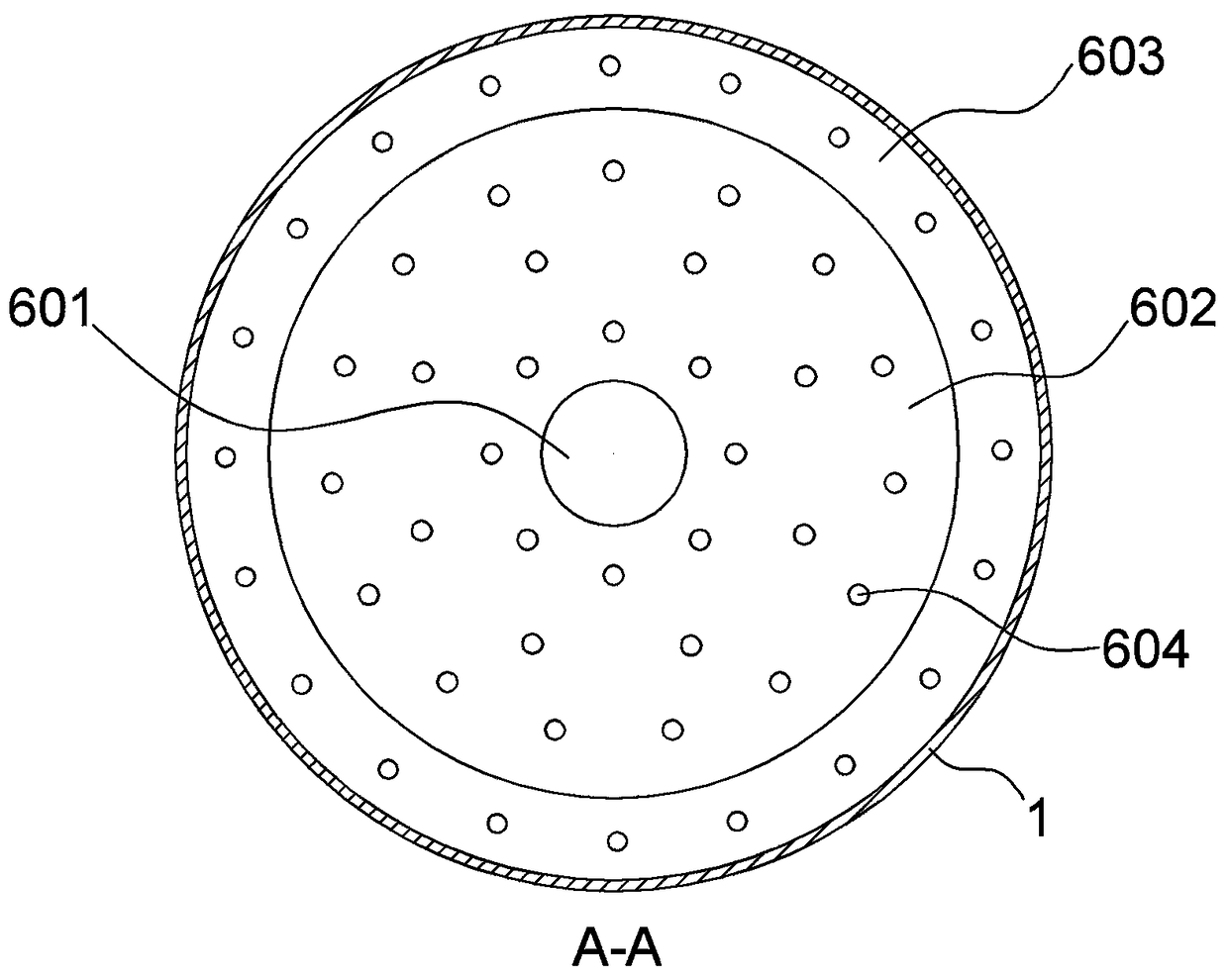

[0030]The single-pool multi-bed biogas fermentation device of the present invention includes a housing 1 and legs 2, the top side of the housing 1 communicates with the interior of the housing 1 and is provided with a feed port 3, and the bottom side of the housing 1 communicates with the inside of the housing 1. A slag outlet 4 is connected to the inside of the shell 1, a methane discharge port 5 is set at the center of the top of the shell 1, and a cloth fermentation unit 6 is stacked in the shell 1, and the cloth fermentation unit 6 includes a flow divider 601, the upper dispersion solidification bed 602, the lower polymerization solidification bed 603 and the cloth exhaust pipe 604, the flow divider 601 is fixedly arranged at the core of the housing 1, the outlet of the feed port 3 is located directly above the flow divider 601, and the cone The surface-shaped upper dispersion solidification bed 602 is arranged below the flow divider 601, and the inverted cone-shaped lower ...

Embodiment 2

[0033] The same as embodiment 1 will not be repeated, the difference is:

[0034] The longitudinal section shape of the splitter 601 is triangular.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com