A smelting method for producing ductile iron castings from scrap steel

A technology for iron castings and scrap steel, applied in the field of iron and steel casting, can solve the problems of large undercooling of molten iron, high hardness of castings, poor inking ability, etc., and achieve the effects of improving elongation, good quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

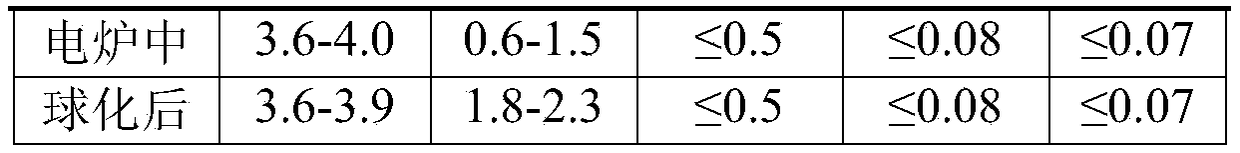

[0027] In December, it was proposed to further reduce the amount of pig iron, and to explore the quality of the scrap steel adding recarburizer ductile iron pipes. As of the 25th, the pig iron addition ratio was 26%, of which 9-14 days, a total of 14 shifts, the pig iron addition ≤ 25% There are 5 shifts; ≤20% has 5 shifts; ≤10% has 1 shift; no pig iron has 3 shifts. Spheroidization, metallography, strength, and hardness have basically no obvious changes, but the elongation increases with the increase in the proportion of scrap steel, and the results are shown below.

[0028] 1. Metallographic structure comparison

[0029] There is no difference from normal ingredients, the rate of 2 grades is 99%

[0030] 2. Comparison of mechanical properties

[0031] Table 3 Comparison of mechanical properties from January to December

[0032]

[0033] 3. Specific data will be added on December 9-16

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size distribution | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com